A kind of electrospinning equipment and its method for preparing electrospinning

An electrospinning and equipment technology, applied in the field of material preparation equipment, can solve problems such as insufficient utilization of rollers, and achieve the effects of easy industrial-scale application, improved use efficiency, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

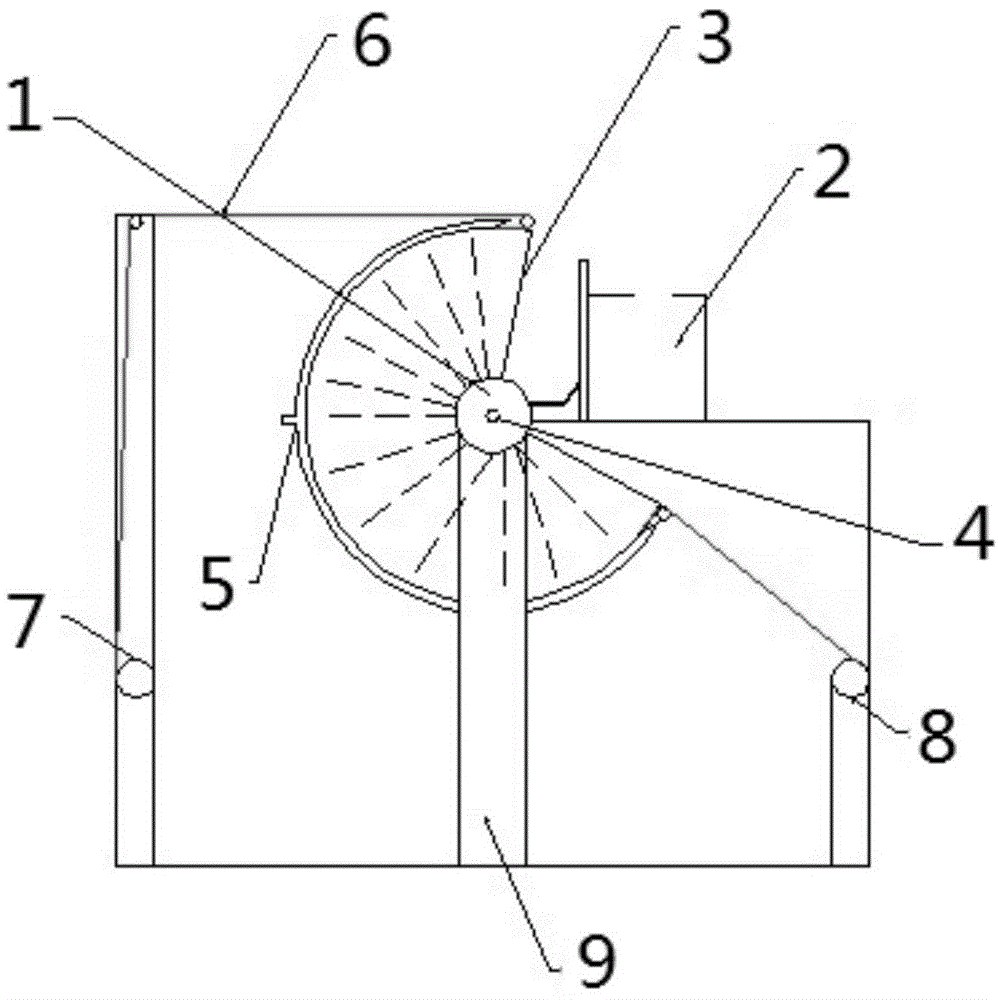

[0042] Depend on figure 1 with figure 2 As shown, the high output electrospinning equipment of the present invention comprises:

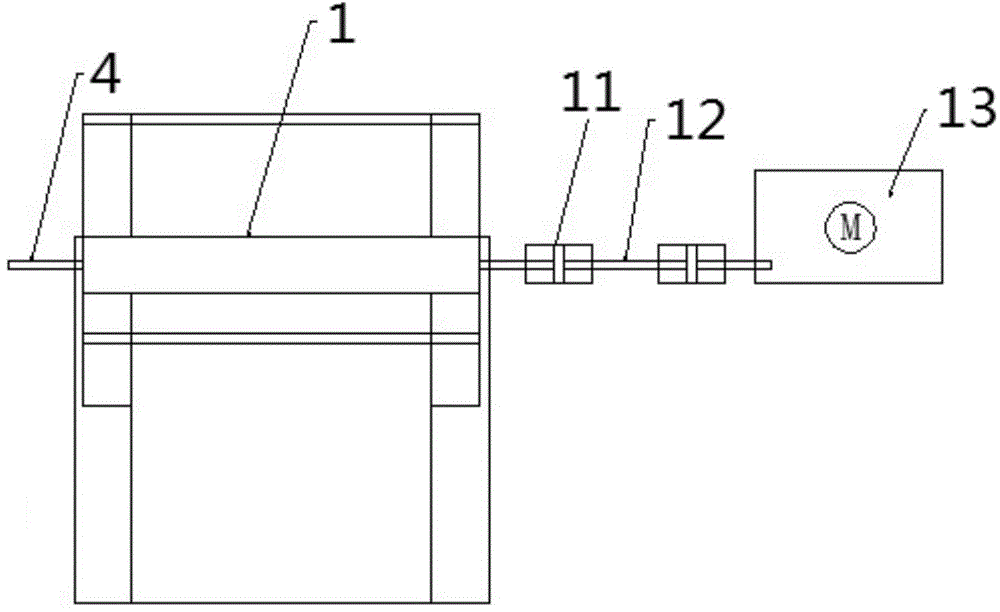

[0043] The metal spraying device 1 is a roller, one end is connected to the positive pole of the power supply through the terminal 4, and the other end is connected to the variable speed motor 13 through a coupling 11 and an insulating rod 12;

[0044] Solution supply system 2, the liquid supply port is a curved surface with the same curvature as the roller and contacts with the metal roller;

[0045] The supporting device of the arc receiving system 3 ensures that the fiber receiving cloth 6 is driven along the receiving system 3, and the arc receiving angle is 345°; the wire casing 5 is connected to the negative pole of the power supply; the driving shaft 7 is connected to the variable speed motor through a coupling to control the entire The transmission speed of the arc-shaped fiber receiving cloth; the driven shaft 8 is used for rewinding and s...

Embodiment 2

[0048] Depend on figure 1 , figure 2 , Figure 3A with Figure 3B As shown, the high output electrospinning equipment of the present invention comprises:

[0049] The metal spraying device 1 is a roller, one end is connected to the positive pole of the power supply through the terminal 4, and the other end is connected to the variable speed motor 13 through a coupling 11 and an insulating rod 12;

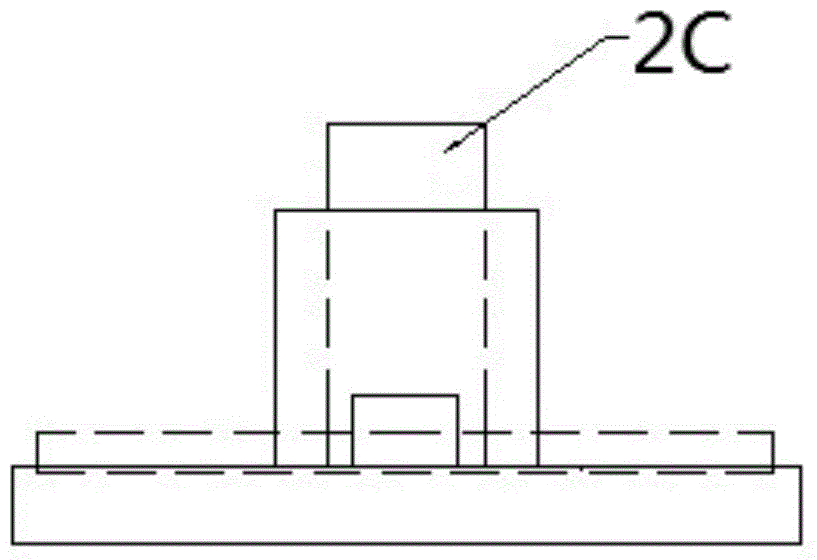

[0050] The solution supply system 2, the liquid supply port is a curved surface with the same curvature as the roller and is in contact with the metal roller, the solution supply system 2 has a sliding plate 2C, and the sliding plate 2C slides up and down to control the pressure of the liquid supply port and the amount of liquid supplied size;

[0051] The supporting device of the arc receiving system 3 ensures that the fiber receiving cloth 6 is driven along the receiving system 3, and the arc receiving angle is 300°; the wire casing 5 is connected to the negative pole of the ...

Embodiment 3

[0054] Depend on figure 1 , figure 2 , Figure 3A , Figure 3B , Figure 4A with Figure 4B As shown, the high output electrospinning equipment of the present invention comprises:

[0055] The metal spraying device 1 is a roller, one end is connected to the positive pole of the power supply through the terminal 4, and the other end is connected to the variable speed motor 13 through a coupling 11 and an insulating rod 12;

[0056] The solution supply system 2, the liquid supply port is a curved surface with the same curvature as the roller and is in contact with the metal roller, the solution supply system 2 has a sliding plate 2C, and the sliding plate 2C slides up and down to control the pressure of the liquid supply port and the amount of liquid supplied Size, the upper contact plate edge 2A has the same curved surface arc section as the metal spraying device 1 and the gap with the metal roller 4 is adjustable, and the lower contact plate edge 2B has the same curved s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com