Bell-type solid melting furnace

The technology of melting furnace and bell jar is applied in the field of bell jar type solid melting furnace, which can solve the problems of self-heavy furnace door, large volume, bad working environment, etc., and achieves the effects of easy production, simple lifting structure and reducing the degree of oxidation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below according to accompanying drawing.

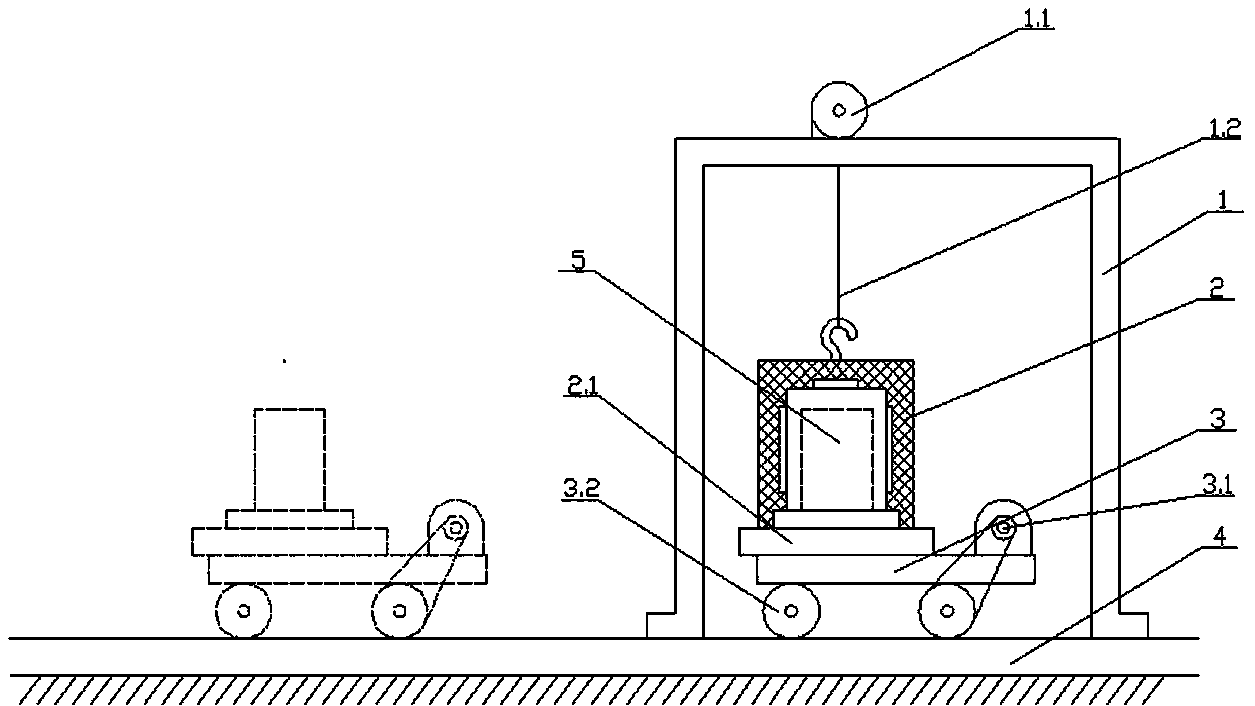

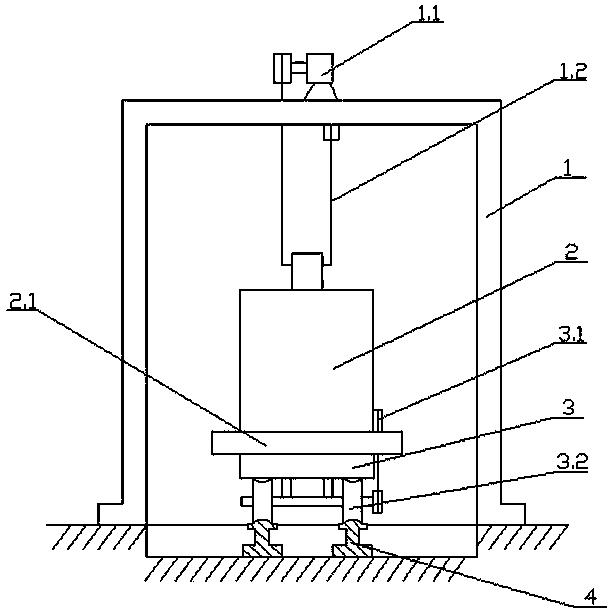

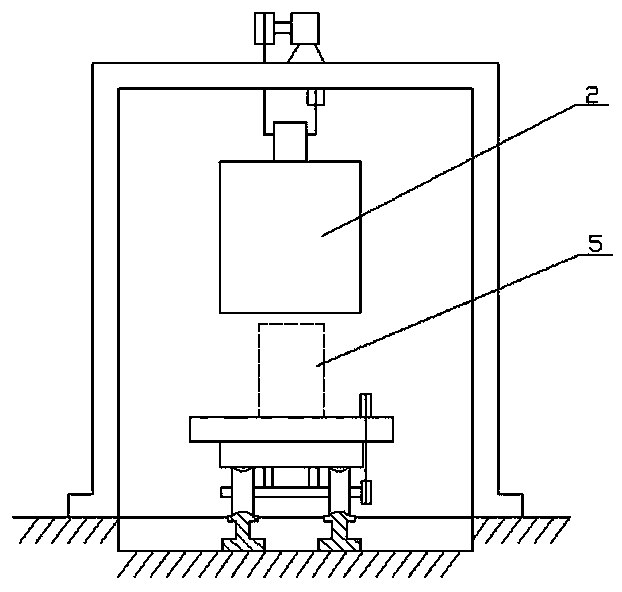

[0016] figure 1 The bell-type solid melting furnace shown includes a gantry 1, a furnace body 2, a trolley 3 and a track 4. The gantry 1 is a rectangular frame, and the gantry 1 straddling two mutually parallel tracks is fixedly connected to the ground, and a hoist 1.1 is provided in the center of the top beam for hoisting the furnace body 2 below. When the gantry 1 lifts the body of furnace 2 to the highest position, the bottom surface of the furnace bottom 2 is higher than the highest position where the workpiece 5 is loaded on the trolley 3 . The trolley 3 is a flatbed structure, the top surface is placed with a furnace bottom 2.1 made of refractory material, the bottom is provided with a roller 3.2, and the trolley 3 is driven by an external reducer 3.1 to move the roller 3.2 reciprocatingly along the track 4. Body of heater 2 is the main component among the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com