Fiber/ceramic/metal composite material bulletproof plate and manufacturing method thereof

A metal composite material, bulletproof plate technology, applied in protective equipment, ceramic layered products, chemical instruments and methods, etc., can solve the problems of poor metal bulletproof effect, layer-to-layer disintegration, etc., to achieve good toughness and prevent disintegration. effect of the phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

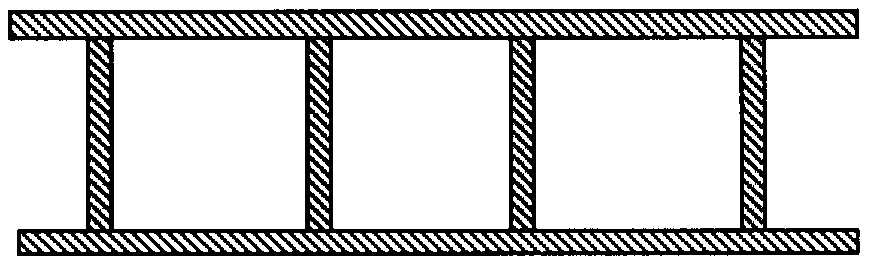

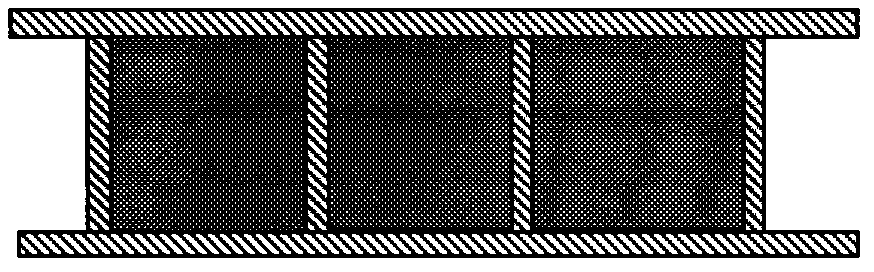

[0028] Two titanium alloy plates with a length and width of 30 mm and a thickness of 3 mm, and two titanium alloy plates with a length of 30 mm, a width of 4 mm and a thickness of 3 mm are used. Titanium alloy frame welded by laser welding. Three ultra-high molecular weight polyethylene sheets with a length of 30 mm, a width of 8 mm and a thickness of 4 mm were prepared and bonded with an adhesive to form a titanium alloy laterally restrained ultra-high molecular weight polyethylene composite sheet. The alumina ceramic plate with a length and width of 30mm and a thickness of 6mm and a carbon fiber plate with a length and width of 30mm and a thickness of 4mm are bonded together with adhesive, and then a layer of ceramic surface is formed on the surface of the ceramic by the ceramic surface alloying method. Titanium alloy, and titanium alloy laterally bound UHMWPE sheet are welded together by brazing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com