Automatic light inspection machine

A technology of automatic light inspection machine and dial, which is applied to instruments, analytical materials, optical testing flaws/defects, etc., can solve problems such as reduction, and achieve the effect of reducing costs, high work efficiency, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

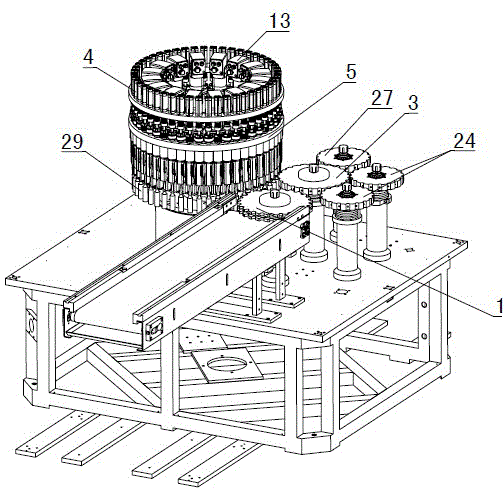

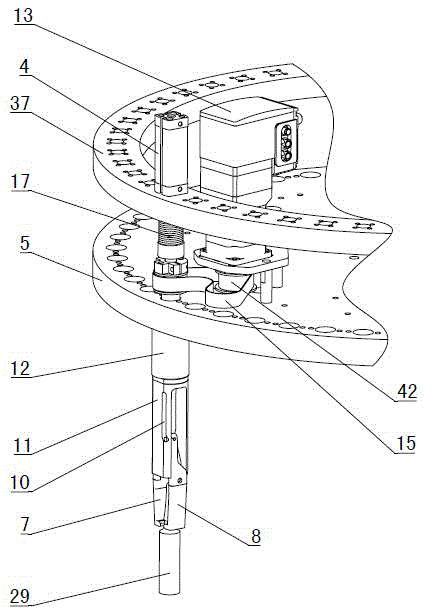

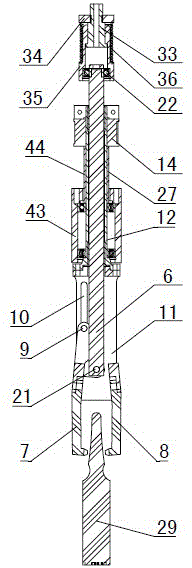

[0033] Figure 1~11 It is the best embodiment of the automatic light inspection machine of the present invention, below in conjunction with the attached Figure 1~11 The present invention will be further described.

[0034] refer to Figure 1~2 , the bottle-carrying turntable 5 is coaxially fixed on the central axis 2, the bottle-feed dial wheel 1 rotates and is fixed on the side of the bottle-in position of the bottle-carrying turntable 5, and the bottle-out dial 3 rotates and is fixed on the bottle-out position of the bottle-carrying turntable 5 On one side of the bottle-out position of the bottle-out dial 3, two bottle-picking dials 24 and one qualified bottle dial 27 are rotated. The ampoules 29 to be detected are transferred to the bottle loading carousel 5, and the synchronous tracking image acquisition mechanism collects the graphics of the ampoules 29 on the bottle loading carousel 5, and each ampule bottle 29 is marked, and the ampoules 29 are loaded with the bottle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com