High-speed engraving and milling electric spindle

An electric spindle, engraving and milling technology, applied in the directions of large fixed members, maintenance and safety accessories, drive devices, etc., can solve the problems of small power and output torque, small motor, etc., to achieve increased power, superior operating performance, and less quantity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

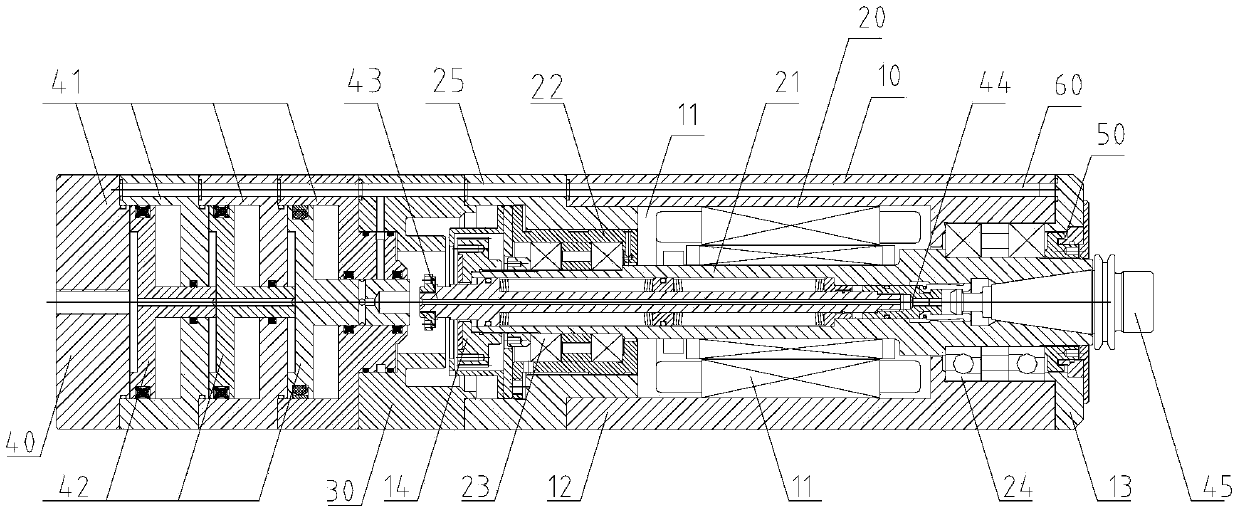

[0021] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

[0022] Please see figure 1 , a high-speed engraving and milling electric spindle of the present invention, which includes a body 10 with an inner cavity 11, a shaft system 20 arranged in the body 10, an aluminum water jacket 30, a broach system 40, an air seal system 50, and a water cooling system 60 and a drive motor (not shown). One end of the body 10 is provided with a lower cover 13 .

[0023] The rotating shaft system 20 includes a shaft core 21 , a bearing housing 22 , a first bearing 23 , a second bearing 24 and a housing housing 25 . The shaft core 21 is axially disposed in the inner cavity 11 of the machine body 10 . The first bearing 23 and the second bearing 24 are disposed at opposite ends of the shaft core 21 along the extending direction of the shaft core 21 for supporting the shaft core 21 . Wherein, the first bearing 23 is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com