Keyway machining method of same-tangency-point eccentric shaft

A processing method and eccentric shaft technology, applied in metal processing equipment, manufacturing tools, details of milling machine equipment, etc., can solve problems such as difficulty in ensuring accuracy and making waste products, so as to improve the accuracy of measurement, facilitate measurement and processing, and avoid problems. The effect of skewed keyway

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The preferred technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

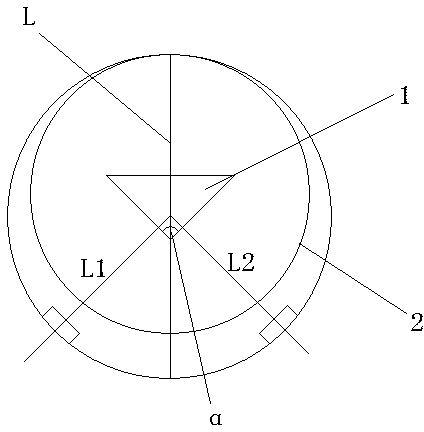

[0018] Such as figure 1 As shown, a kind of keyway processing method of the eccentric shaft at the same tangent point of the present invention comprises the following steps:

[0019] A. Draw a diameter line L on the end surface of the cylindrical casting; find three points on the circle, connect them into two line segments, and make the perpendicular bisectors of the two line segments respectively. The intersection point is the center of the circle, and draw the diameter arbitrarily through the center of the circle Line L.

[0020] B. Draw an isosceles triangle reference piece 1 whose base is perpendicular to the diameter line L on the end surface of the cylindrical casting. The center of the end surface of the cylindrical casting is located in the triangle reference piece 1. ; Define α as 80°, then the apex angle of the isoscel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com