Method for machining input shaft of main reducing gear of heavy load automobile

A main reducer and processing method technology, which is applied in the processing field of the input shaft of the main reducer of heavy-duty vehicles, can solve problems such as short service life, endangering safe driving, and low production efficiency, so as to improve product quality and production efficiency, avoid Potential safety hazards and the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

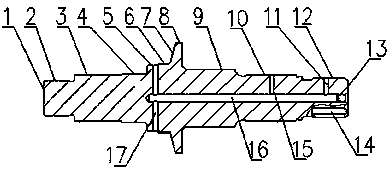

[0020] The present invention will be further described below in conjunction with accompanying drawing:

[0021] Referring to the accompanying drawings, a processing method for the input shaft of the main reducer of a heavy-duty vehicle is characterized in that it includes the following steps: 1), blanking and forging; Based on the end face 18 of the flange, rough turn the short end face and each outer circle; U-turn is based on the short end end face 1 and the outer circle of the spline A3, rough turn the long end end face 13 and each outer circle; control the runout of the outer circle, Meet the size requirements of the drawing; 3), surface treatment: quench and temper the workpiece as a whole, and the hardness of quench and temper is HRC28~32. : On the CNC lathe, take the outer circle A of the bearing gear and the end face 4 as the benchmark, finish turning the long end end face and the outer circles everywhere, and drill the center hole on the end face B13; turn around and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com