One-step molded V-shaped plate forming technology and molded V-shaped plate

A molding die and process technology, applied in the pretreatment of molding materials, manufacturing tools, wood processing utensils, etc., can solve the problems of high energy consumption and high manufacturing costs for filling core boards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

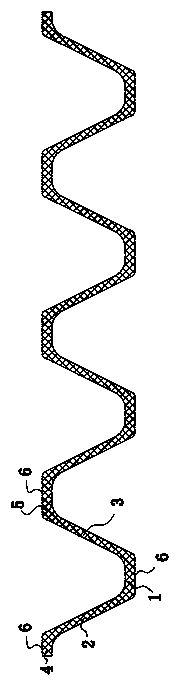

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0021] A process for one-time forming and pressing a "V" shaped plate, characterized in that it includes the following steps,

[0022] The first step is to collect the corner waste produced in the production of composite doors, put the corner waste into the pulverizer, then expose and dry, and then send the pulverized material to the glue mixer to mix the glue. The powder material is paved on the loading trolley on the conveyor belt with a fixed thickness, and then sent to the cold press by the loading trolley for pre-pressing to form a raw material slab;

[0023] In the second step, the raw material slab in the first step is transported to a mold with a "V" groove in a hot press through a conveyor belt and hot-pressed to form a "V"-shaped plate. In this embodiment, the "V"-shaped plate with stable mechanical properties is supported by the waste leftover mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com