Flexible conveying system based on RGV and AGV

A conveying system and flexible technology, which is applied in the direction of conveyors, conveyor objects, mechanical conveyors, etc., can solve the problems of high equipment and maintenance costs, low conveying efficiency, and large space occupied by tracks, so as to avoid low conveying efficiency, The effect of high conveying efficiency and low overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

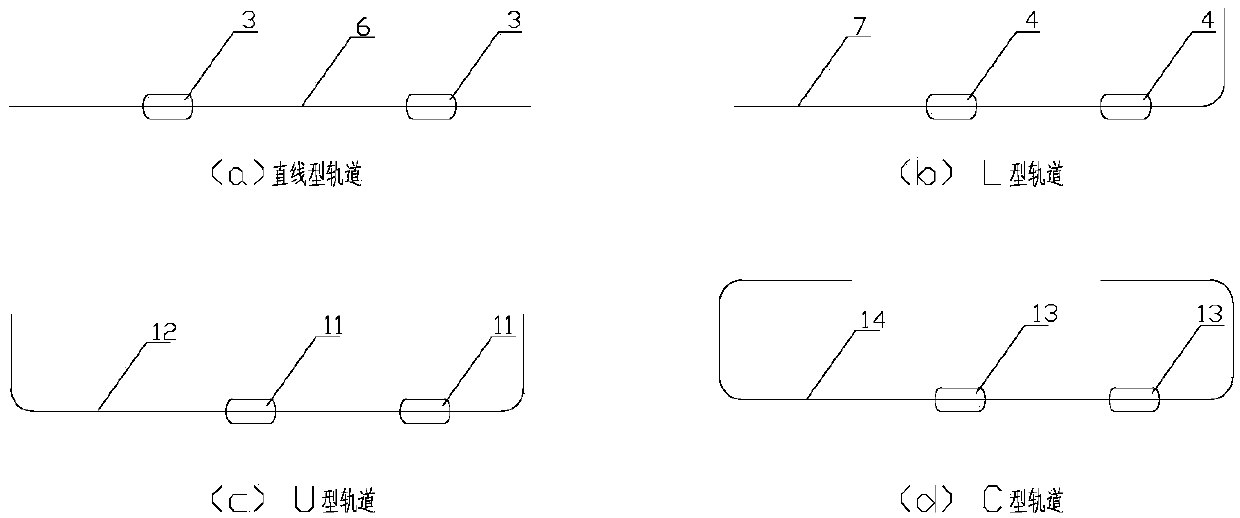

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

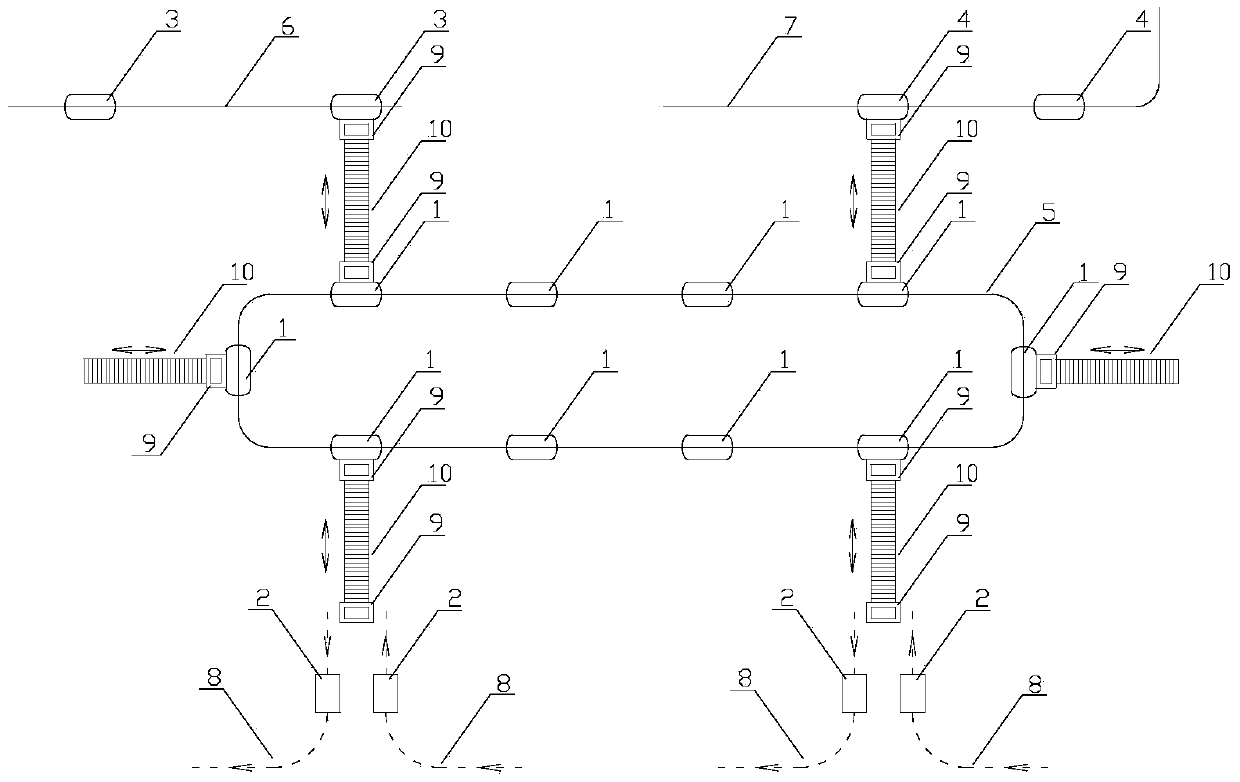

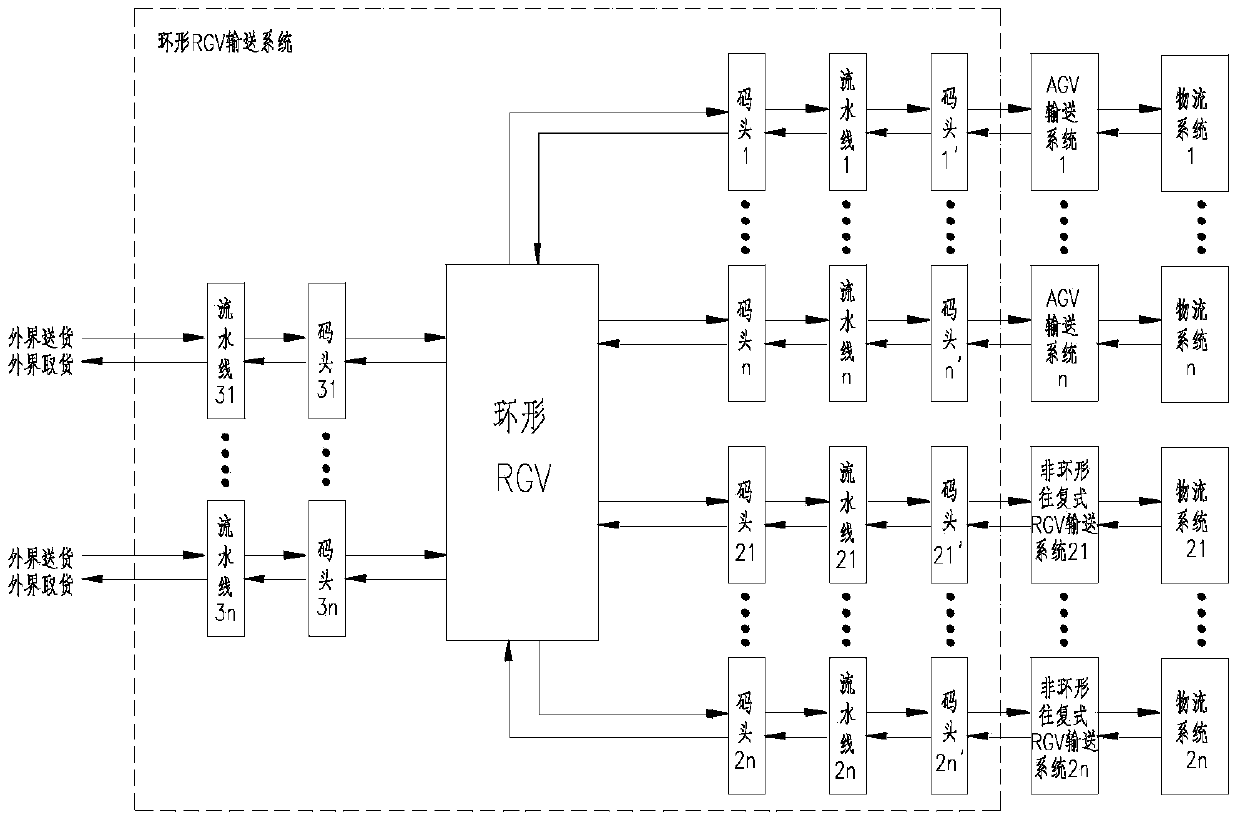

[0025] Such as figure 1 As shown, the flexible conveying system based on RGV and AGV of the present invention includes three major sub-conveying systems: an annular RGV conveying system, several AGV conveying systems and several non-circular reciprocating RGV conveying systems, and the annular RGV conveying system passes through paired The assembly line 10 between the wharf 9 and the wharf 9 is connected with the AGV conveying system and the non-circular reciprocating RGV conveying system, wherein,

[0026] The circular RGV conveying system is the hub of the entire flexible conveying system, including circular RGV1, circular track 5, wharf 9 and assembly line 10, through which logistics goods enter and exit the other two conveying subsystems, circular RGV1 is evenly distributed on circular track 5 , the wharf 9 is placed near the circular tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com