Oxygenator

A technology of oxygen generator and control valve, applied in the field of medical equipment, can solve the problems of shortened service life of molecular sieve and high working noise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings.

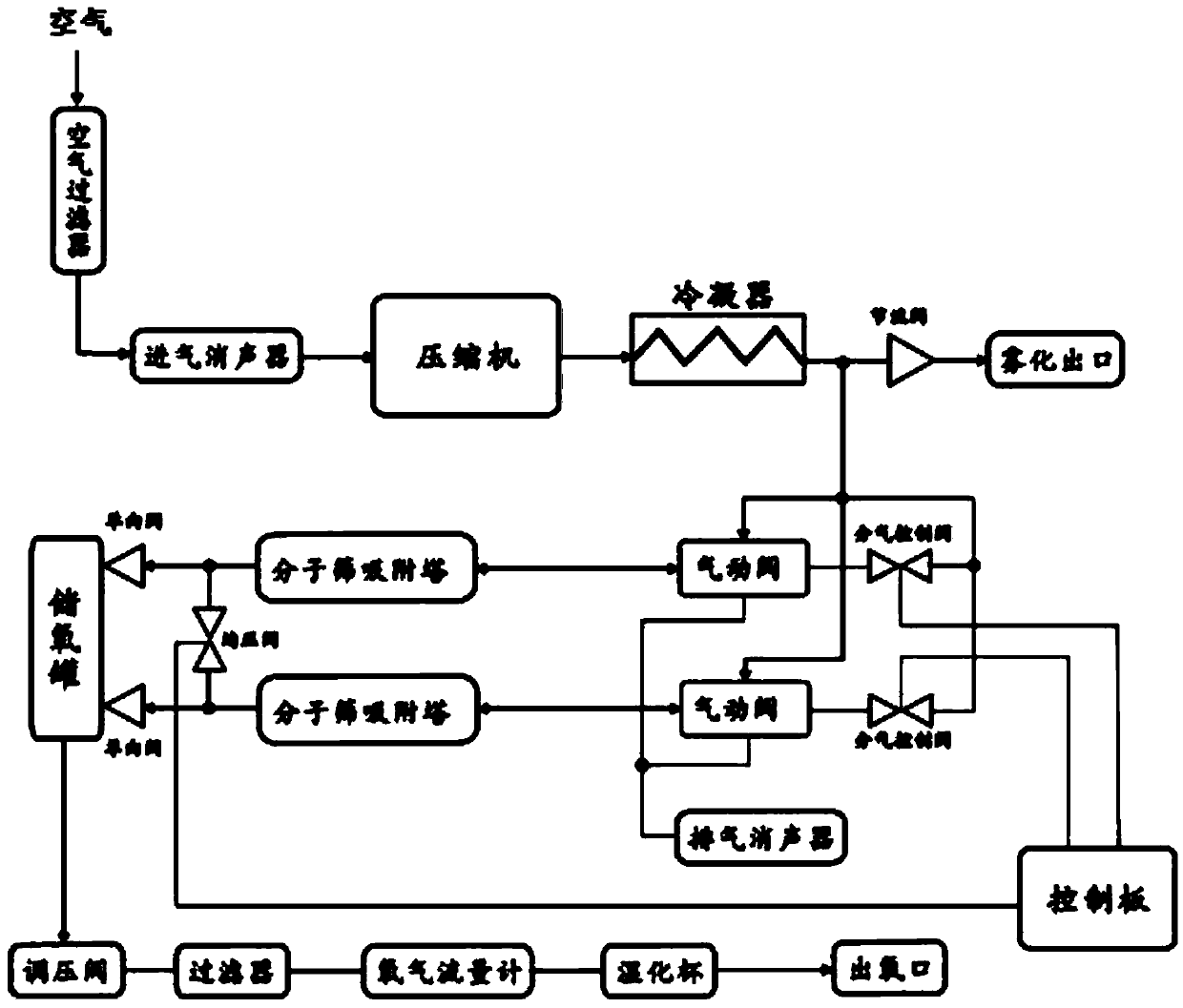

[0035] Such as figure 1 As shown, an oxygen generator is characterized in that it includes an air filter, an air inlet muffler, a compressor, a condenser, an adsorption device, an oxygen storage tank, a pressure regulating valve, a filter, and an oxygen flow meter connected in sequence. , humidification cup and oxygen outlet.

[0036] The gas outlet of the condenser is also connected with the atomization outlet, and a throttling valve is arranged between the gas outlet of the condenser and the atomization outlet.

[0037] The number of the adsorption devices is at least 2 and arranged side by side. The adsorption device includes a gas distribution control valve, a pneumatic valve and a molecular sieve adsorption tower connected in sequence. The gas inlet of the gas distribution control valve is connected to the condenser The air outlet is connected, the air outlet of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com