Method and device for controlling solid-state fermentation temperature of white spirit

A technology for solid-state fermentation and liquor, which can be used in fixed conduit components, preparation of alcoholic beverages, lighting and heating equipment, etc., and can solve problems such as unsatisfactory temperature control effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

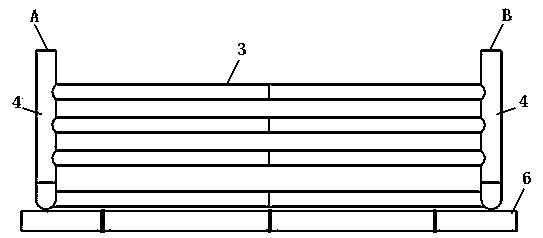

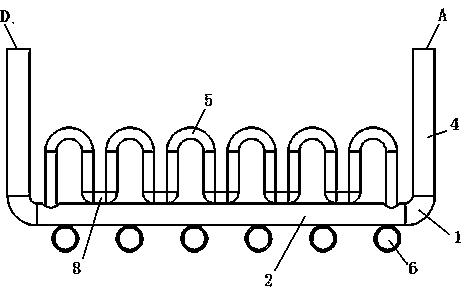

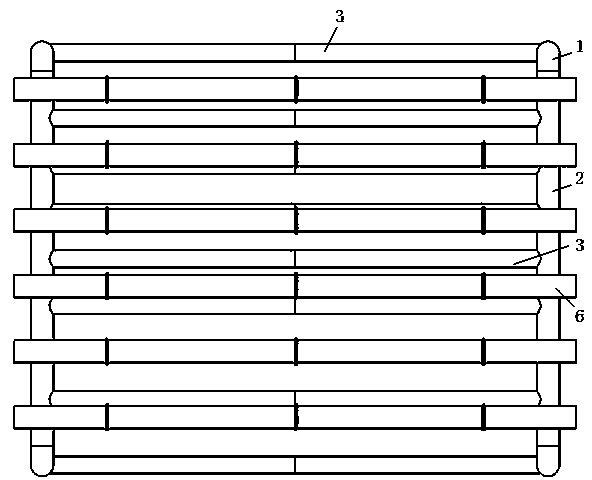

[0056] A device for controlling the fermentation temperature in a liquor solid-state fermentation cellar, comprising a heat exchange medium supply system, a temperature monitor and a heat exchange frame arranged in the cellar, the heat exchange frame has an opening on the top surface, a bottom surface and four side standing The square frame of the heat exchange tube is fixed on the surface, and one or more temperature sensors are evenly distributed on the wall of the heat exchange tube. The temperature sensor and the temperature monitor transmit the temperature data of each area through wired or wireless data transmission. The temperature monitor is provided with a display capable of displaying the temperature, and the water inlet of the heat exchange tube is connected with the heat exchange medium supply system through a valve, so as to achieve high temperature and low temperature heat exchange medium ( Such as switching between hot water and cold water), and control of the fl...

Embodiment 2

[0092] A device for controlling the fermentation temperature in a liquor solid-state fermentation cellar, comprising a heat exchange medium supply system, a temperature monitor and a heat exchange frame arranged in the cellar, the heat exchange frame has an opening on the top surface, a bottom surface and four side standing The square frame of the heat exchange tube is fixed on the surface, and one or more temperature sensors are evenly distributed on the wall of the heat exchange tube. The temperature sensor and the temperature monitor transmit the temperature data of each area through wired or wireless data transmission. The temperature monitor is provided with a display capable of displaying the temperature, and the water inlet of the heat exchange tube is connected with the heat exchange medium supply system through a valve, so as to achieve high temperature and low temperature heat exchange medium ( Such as switching between hot water and cold water), and the control of th...

Embodiment 3

[0106] A temperature control device is installed in a liquor solid-state fermentation cellar with a length of 4.1m, a width of 2.0m, and a depth of 1.8m. Select the described temperature control device described in embodiment 1 or embodiment 2. Two kinds of heat exchange plates with a length of 4m and a width of 2m and a length of 2m and a width of 2m used in the wall of the cellar are cast, two each, and the distance between each heat exchange tube of the heat exchange plate is 40cm. 2-3 temperature sensors are installed on the board. Then cast two sets of heat exchange frames (6 heat exchange frames in total) used in the three-layer cellar. Each heat exchange frame is 1.8m long, 1.6m wide, and 0.6m high. The serpentine tubes are separated by 40cm, and 3-5 temperature sensors are installed at different positions on each heat exchange surface of the heat exchange frame. The temperature sensor and temperature monitor transmit the temperature data of each area to the temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com