Quick-valve magnetic control gravity emergency drive device

A driving device and fast technology, applied in the direction of valve device, valve operation/release device, valve details, etc., can solve the problems of crude oil leakage, high maintenance cost, heavy casualties, etc., to eliminate process overpressure and realize automatic The effect of regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the present invention easier to understand, the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

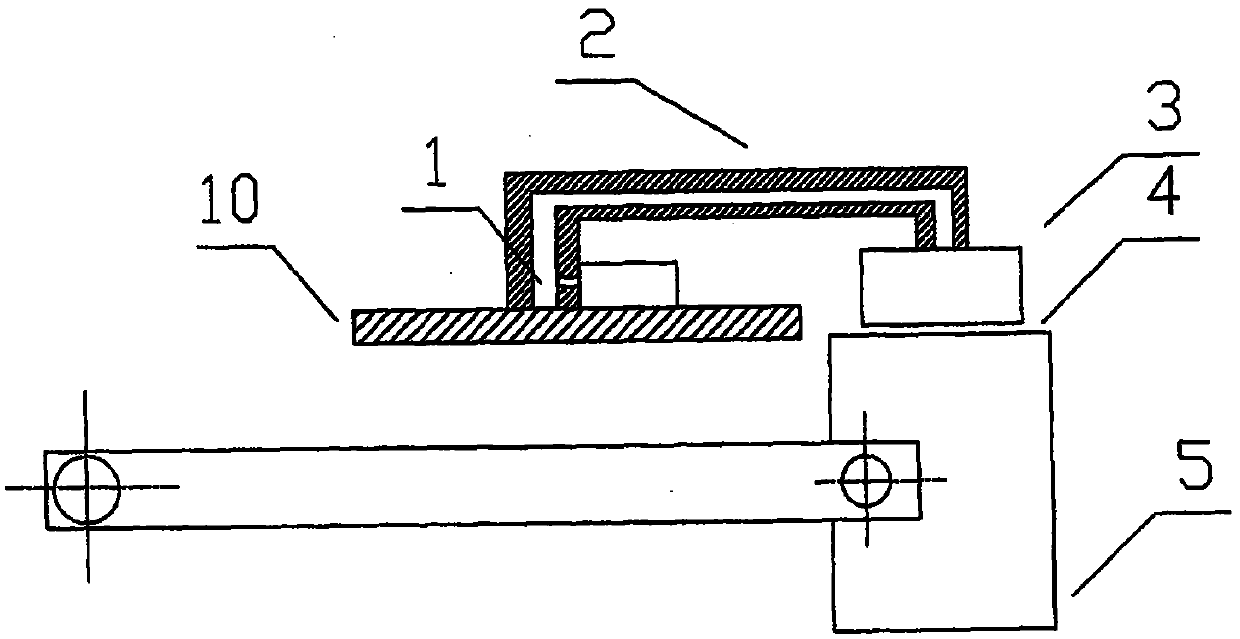

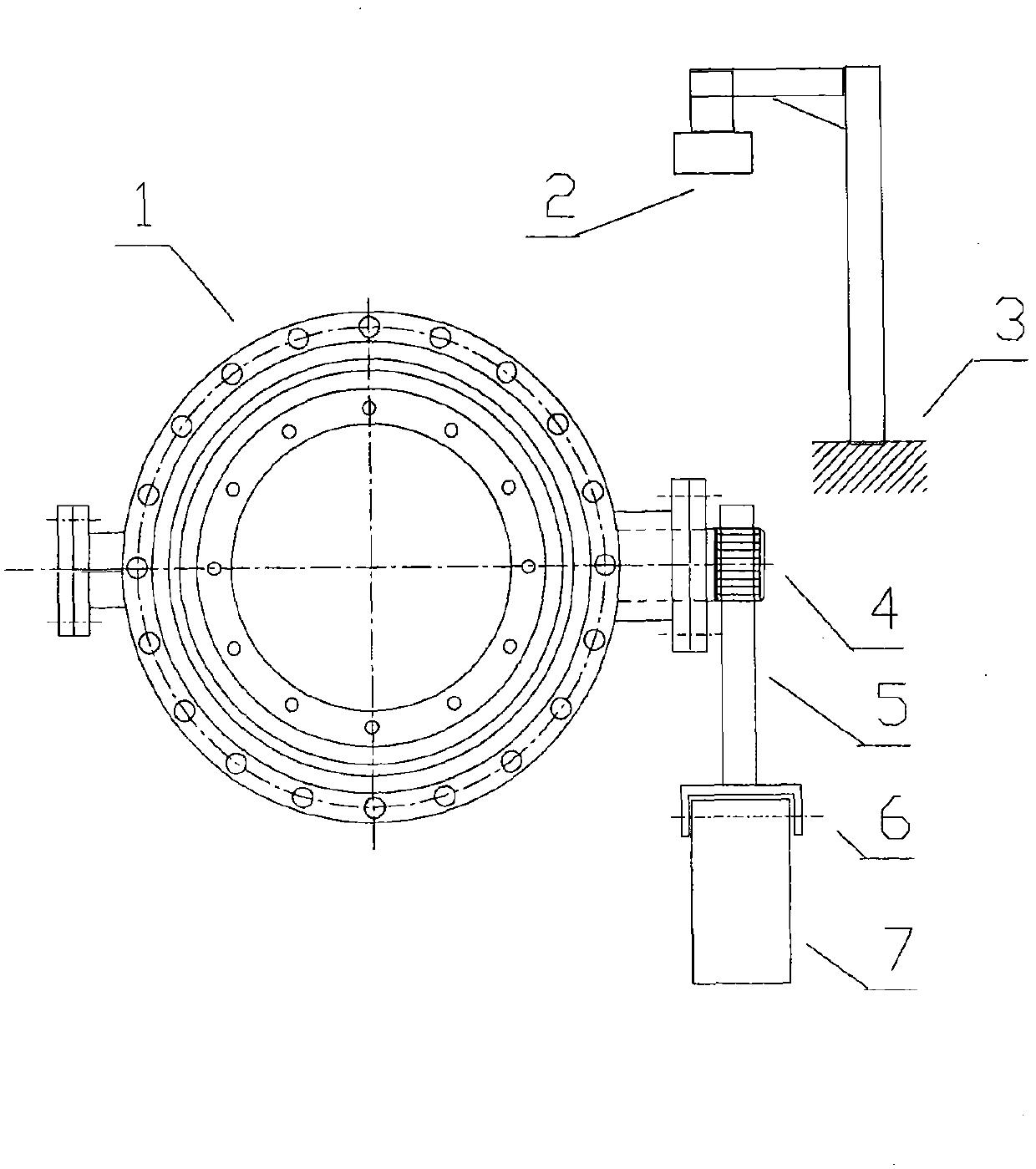

[0025] Refer to attached figure 1 , the fast valve magnetically controlled gravity emergency driving device of the present invention includes a driving device body and a mechanical framework matched with the fast valve;

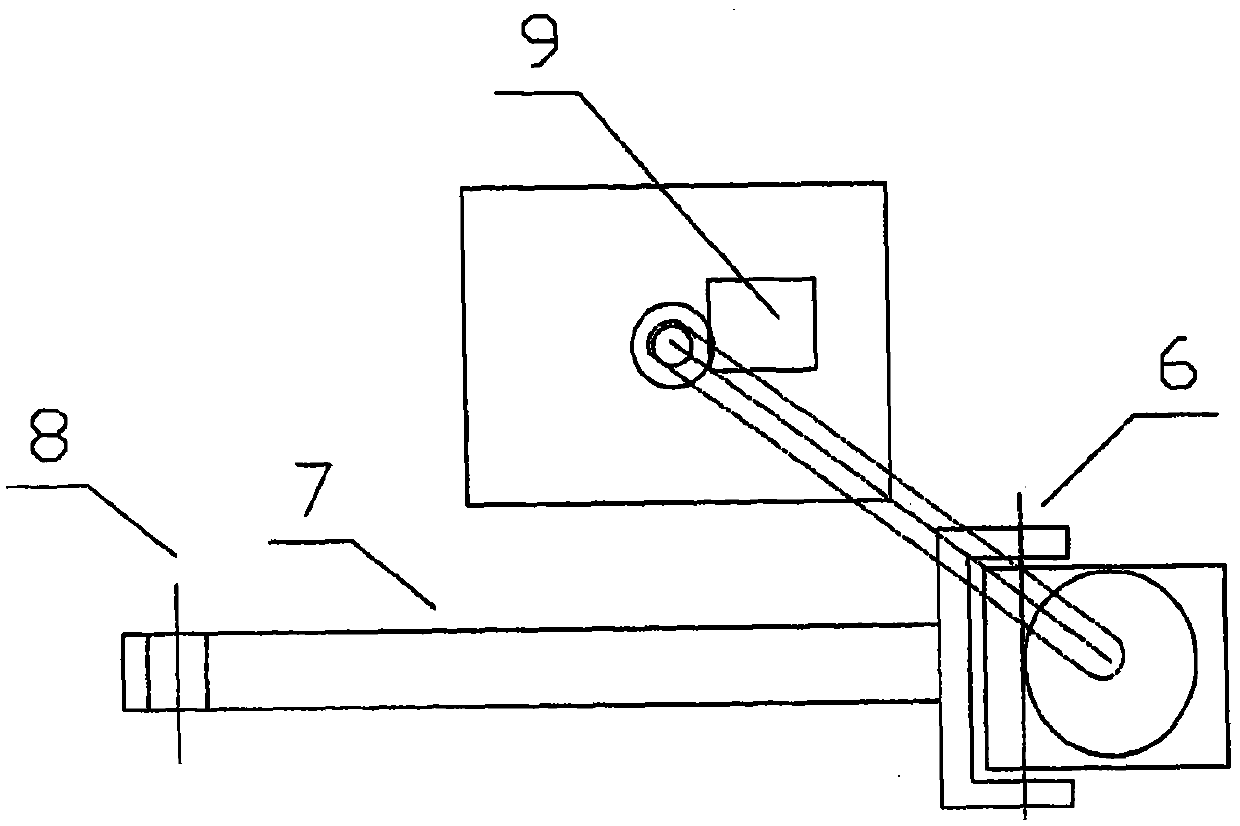

[0026] The main body of the fast valve magnetron gravity emergency driving device includes a magnetron chuck 3, and the cable of the magnetron chuck 3 passes through the magnetron chuck cable channel 1 inside the magnetron chuck steel frame 2 and the magnetic field program Controller 9 ( figure 2 ) to realize the communication connection. When combined with lever arm 7( figure 2 ) After the counterweight 5 movably connected to the connecting pin 6 contacts the magnetron sucker 3, the magnetic field program controller 9 ( figure 2 ) is magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com