Condenser for household refrigerator

A technology for condensers and refrigerators, which is used in household refrigeration devices, evaporators/condensers, household appliances, etc., can solve the problem that the condensed liquid film in the tube cannot be discharged in time, the refrigerant flow resistance in the tube is large, and the condensation heat transfer efficiency is low, etc. problems, to achieve the effect of thinning the flow boundary layer, improving the refrigeration performance and energy efficiency level, and increasing the dryness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

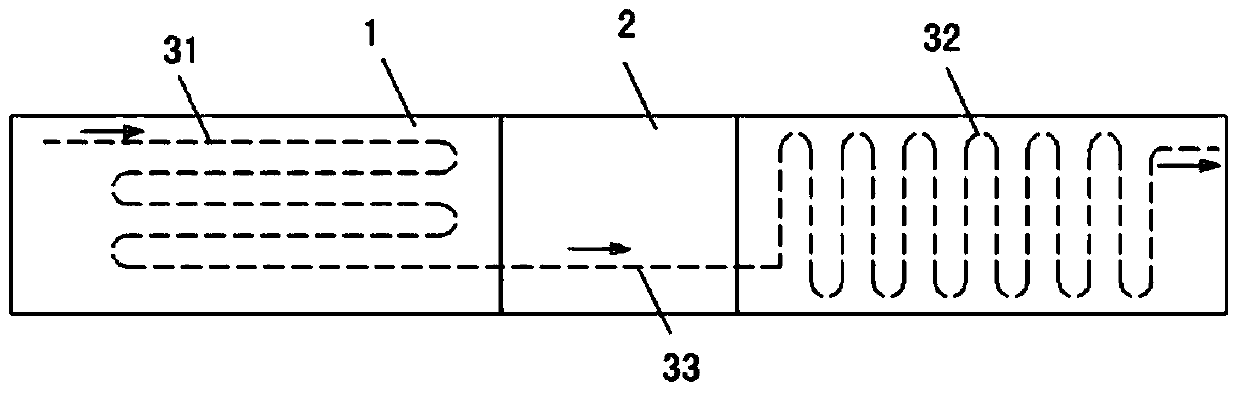

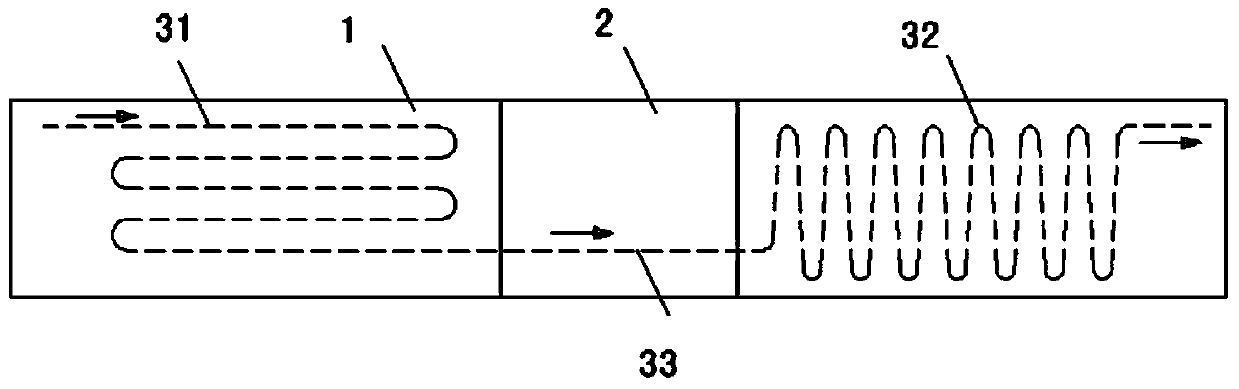

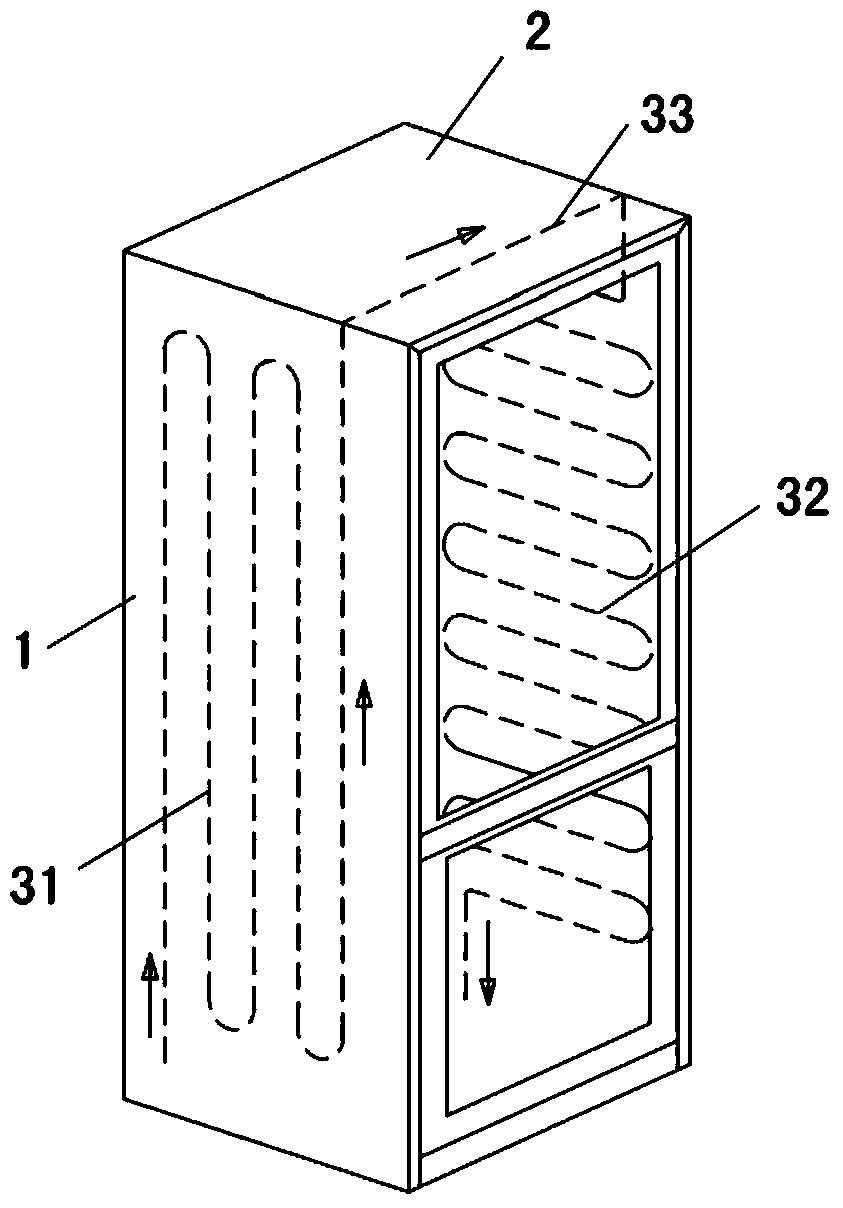

[0024] Such as figure 1 , figure 2 As shown, the condenser in this embodiment includes a vertically arranged condenser front coil 31 and a horizontally arranged condenser rear coil 32; the condenser front coil 31 and the condenser rear coil 32 are respectively attached and fixed to different refrigerators of the refrigerator. Inside the side plate 1 , the coiled pipe 31 at the front section of the condenser and the coiled pipe 32 at the rear section of the condenser are integrally arranged, and the two are connected by a condenser jumper pipe 33 arranged inside the top plate 2 of the refrigerator. The high-temperature refrigerant vapor discharged from the compressor 4 flows through the coiled pipe 31 at the front section of the condenser to the coiled pipe 32 at the rear section of the condenser; the flow direction of the refrigerant in the coiled pipe 32 at the rear section of the condenser is from top to bottom. In specific implementation, different refrigerator side panel...

Embodiment 2

[0030] Such as Figure 4 , Figure 5 As shown, the condenser in this embodiment includes a vertically arranged condenser front coil 31 and a horizontally arranged condenser rear coil 32; the condenser front coil 31 and the condenser rear coil 32 are respectively attached and fixed on the left and right sides of the refrigerator In a refrigerator side panel 1; the coiled pipe 31 of the front section of the condenser and the coiled pipe 32 of the rear section of the condenser are arranged in separate parts, and the two are welded through the connecting pipe 34. The high-temperature refrigerant vapor discharged from the compressor 4 flows through the coiled pipe 31 at the front section of the condenser to the coiled pipe 32 at the rear section of the condenser; the flow direction of the refrigerant in the coiled pipe 32 at the rear section of the condenser is from top to bottom.

[0031] Figure 5 It is a schematic diagram of the refrigerator after assembly and molding. The pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com