Method for measuring the coating amount of insulating coating on the surface of electrical steel

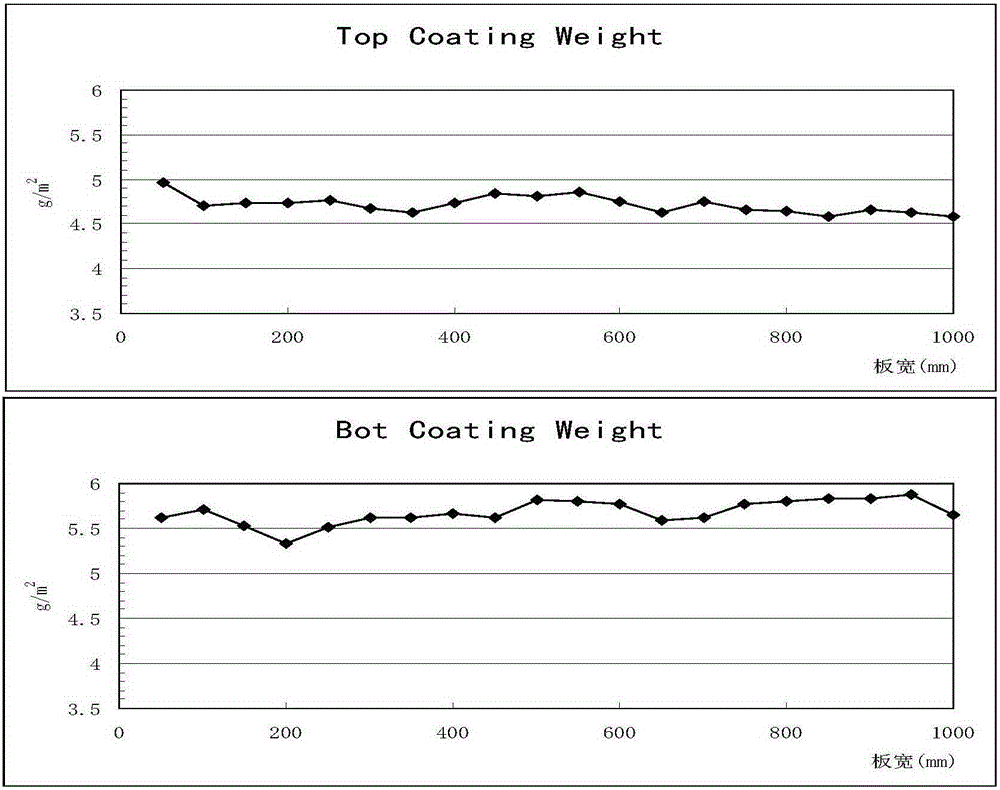

A technology of insulating coating and measuring method, which is applied in the direction of measuring devices, instruments, and using wave/particle radiation, etc., can solve problems such as cumbersome methods, inability to accurately reflect the coating amount of the board width, and low representativeness, etc., to achieve the goal of coating Precise layer control, improved measurement accuracy and repeatability, and reduced detection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific implementation.

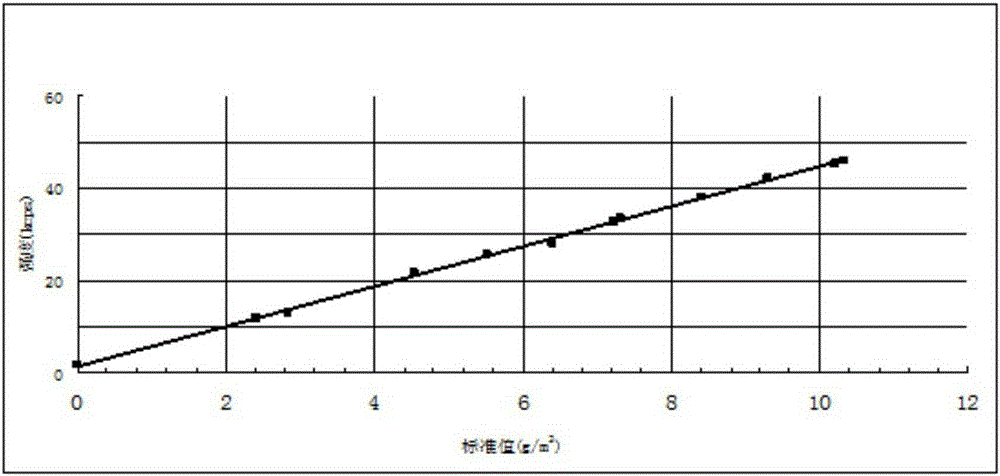

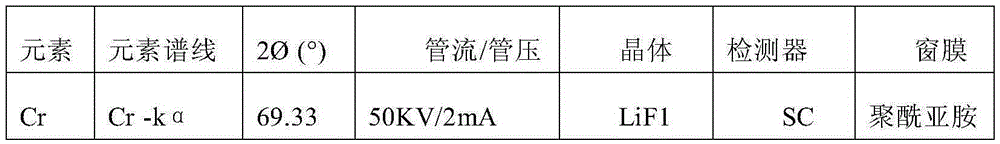

[0031] Since the electrical steel substrate does not contain or contain negligible Cr or P elements, while the currently commonly used organic coatings contain Cr or P elements, in the specific embodiment of the present invention, the electrical steel used is oriented steel, and the coating solution Contains chromate, therefore, Cr can be used as a characteristic element in this coating.

[0032] The measurement method of the insulating coating coating amount on the electrical steel surface is as follows:

[0033] 1) Select Cr as the characteristic element;

[0034] 2) Preparation of standard samples

[0035] A. Cleaning of electrical steel substrate

[0036] The size of the electrical steel substrate is not limited, and can be set independently according to actual needs, preferably 150×150mm. The surface of the substrate is req...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com