Amplitude test method of water lubrication rubber tail bearing based on machine vision technology

A rubber tail bearing and machine vision technology, which is applied to instruments, measuring devices, and measuring ultrasonic/sonic/infrasonic waves, etc., can solve the problems of large test method errors and inability to truly reflect the vibration of water-lubricated rubber tail bearings, etc., to reduce Effects of test difficulty and improved measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

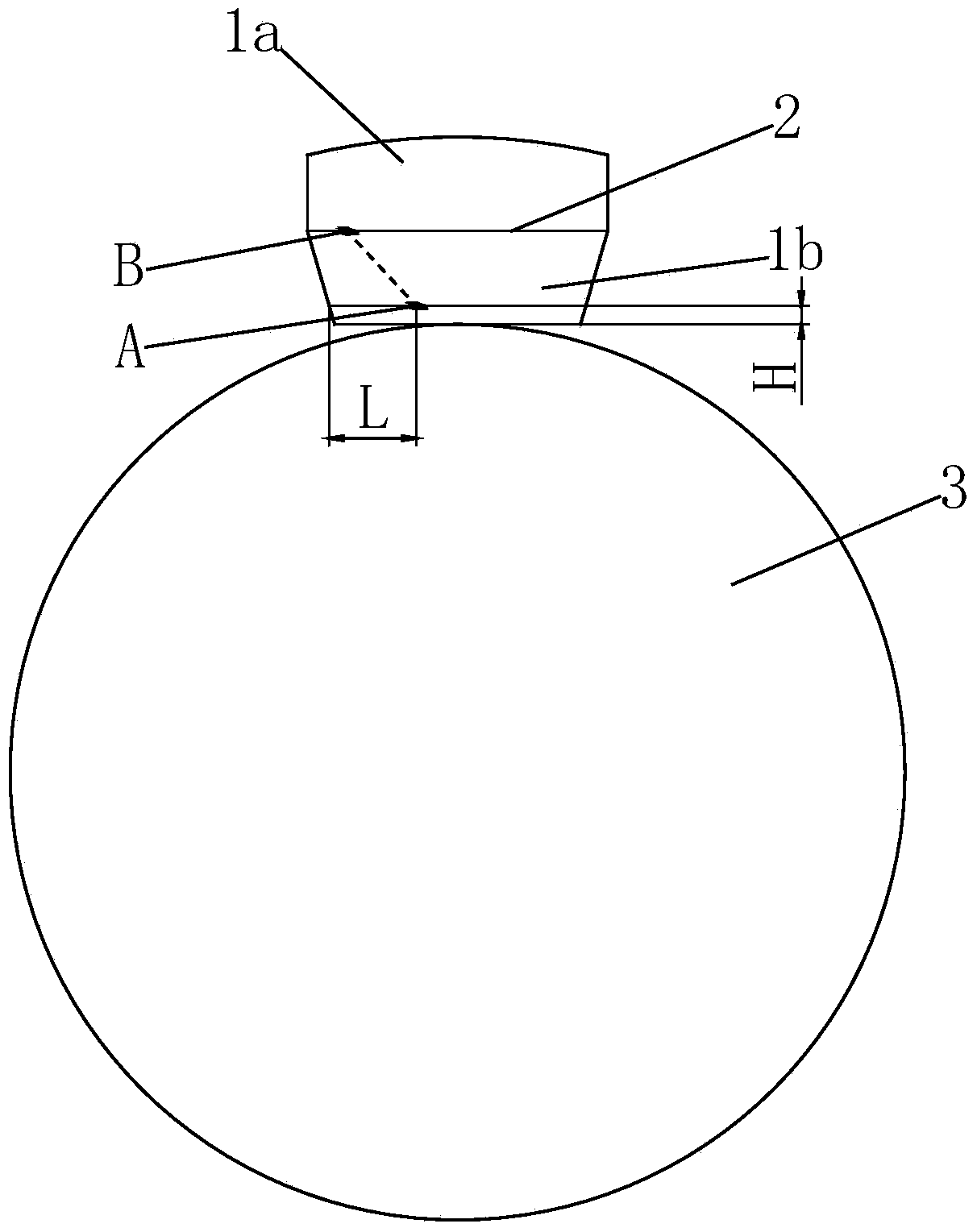

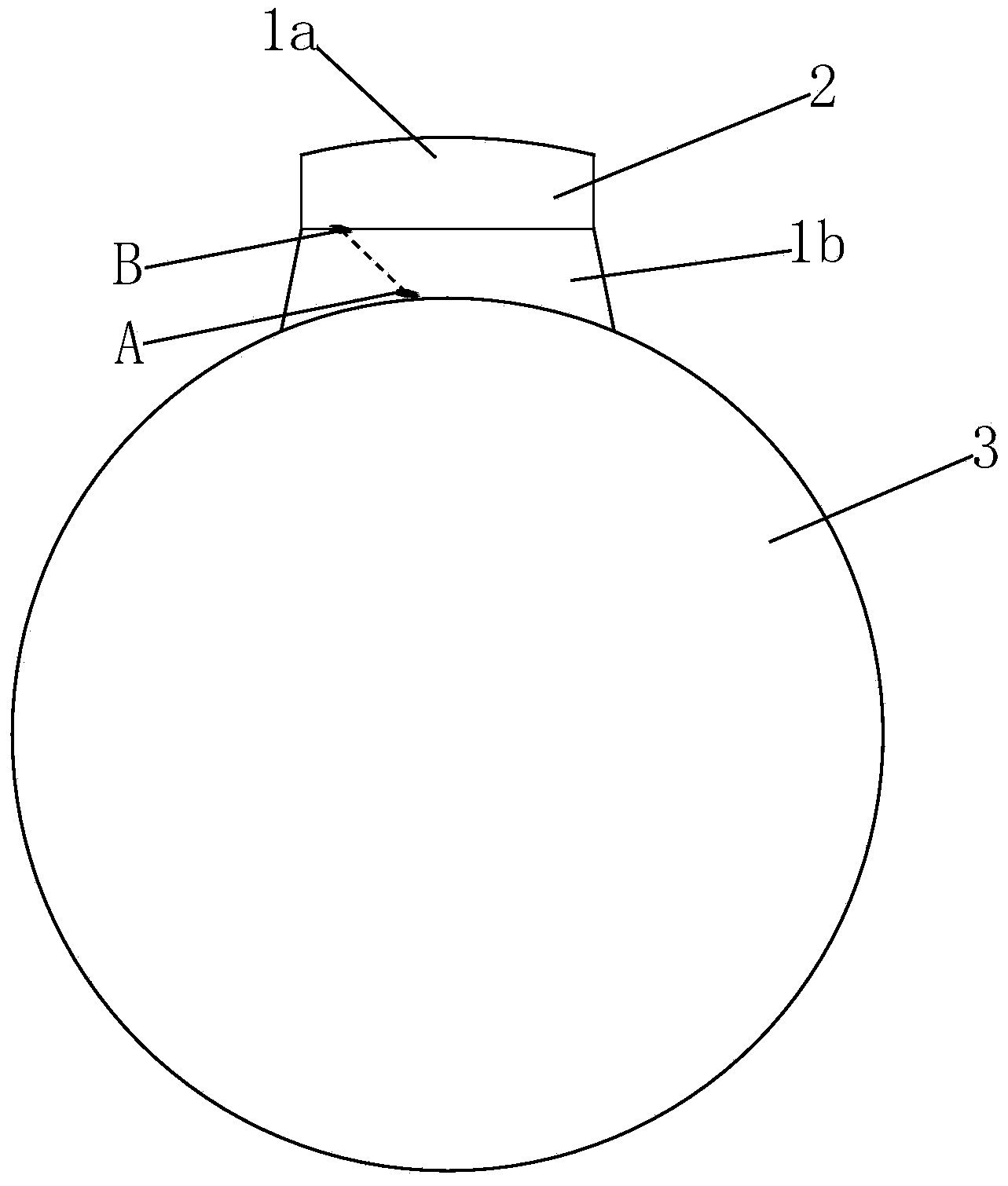

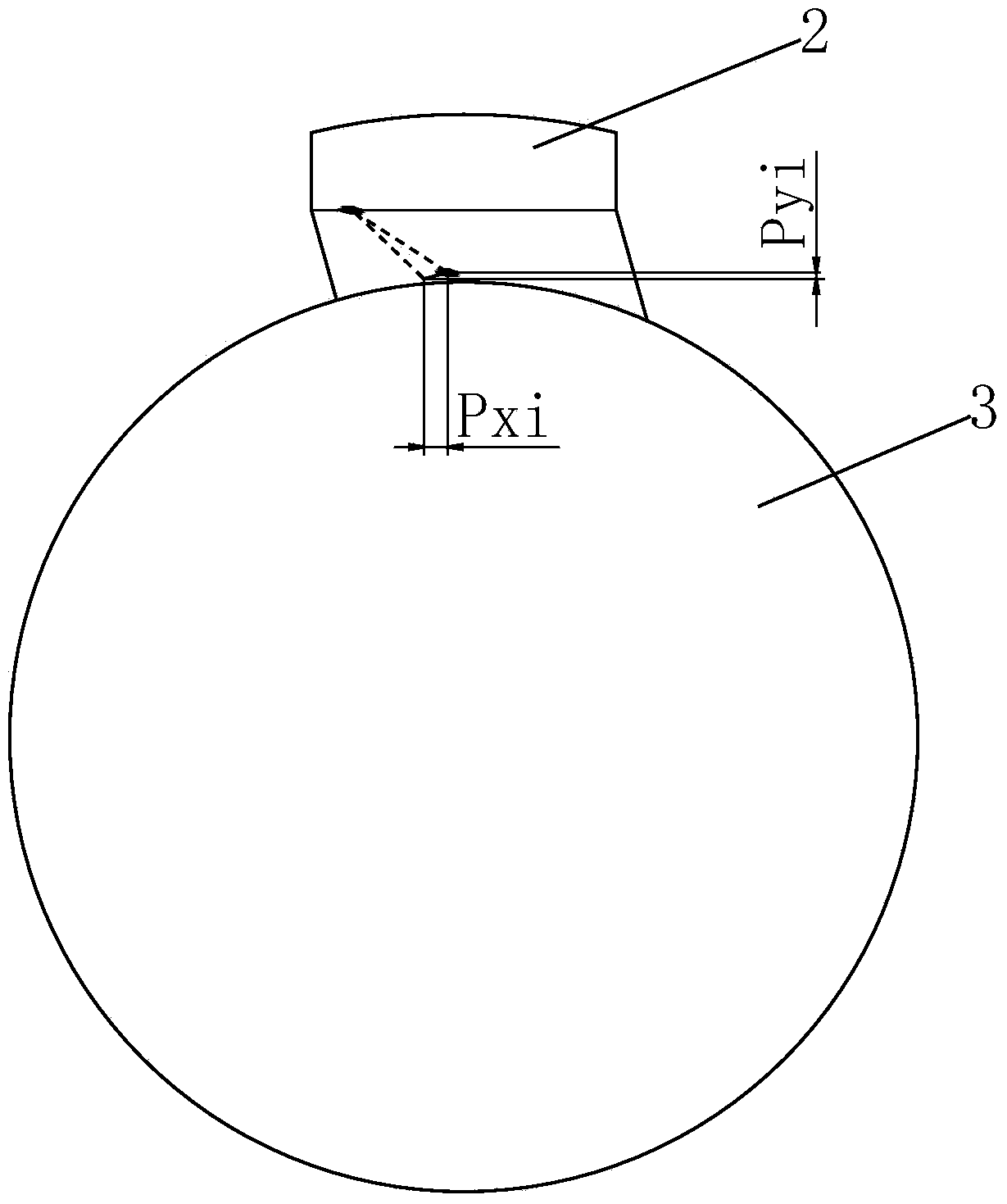

[0046] Embodiment 1: A water-lubricated rubber tail bearing amplitude test method based on machine vision technology. The water-lubricated rubber tail bearing 1 includes a bearing backing 1a and several slats 1b evenly arranged on the inner wall of the bearing backing 1a (see Figure 12 ), including the following steps:

[0047] (1) Measure the maximum vibration frequency f=1kHz of the water-lubricated rubber tail bearing 1, and determine the shooting frame number of the high-speed camera F=2.5kHz according to the maximum vibration frequency f, F>2f, so as to ensure that the high-speed camera can clearly capture the test Track the motion state of point A;

[0048](2) Take a strip 1b and the corresponding part of the bearing backing 1a from the water-lubricated rubber tail bearing 1 as the test piece 2 for testing (see figure 1 , figure 2 and image 3 ); Of course, two or more slats 1b can also be taken as test block 2;

[0049] (3) Mark the test tracking point A on the si...

Embodiment 2

[0062] Embodiment 2: A water-lubricated rubber tail bearing amplitude test method based on machine vision technology. The water-lubricated rubber tail bearing 1 includes a bearing backing 1a and several slats 1b evenly arranged on the inner wall of the bearing backing 1a (see Figure 12 ), including the following steps:

[0063] (1) Measure the maximum vibration frequency f=1kHz of the water-lubricated rubber tail bearing 1, and determine the shooting frame number of the high-speed camera F=2.5kHz according to the maximum vibration frequency f, F>2f, so as to ensure that the high-speed camera can clearly capture the test Track the motion state of point A;

[0064] (2) Take a strip 1b and the corresponding part of the bearing backing 1a from the water-lubricated rubber tail bearing 1 as the test piece 2 for testing (see figure 1 , figure 2 and image 3 ); Of course, two or more slats 1b can also be taken as test block 2;

[0065] (3) Mark the test tracking point A on the s...

Embodiment 3

[0078] Embodiment 3: A water-lubricated rubber tail bearing amplitude test method based on machine vision technology. The water-lubricated rubber tail bearing 1 includes a bearing backing 1a and several slats 1b evenly arranged on the inner wall of the bearing backing 1a (see Figure 12 ), including the following steps:

[0079] (1) Measure the maximum vibration frequency f=1kHz of the water-lubricated rubber tail bearing 1, and determine the shooting frame number of the high-speed camera F=2.5kHz according to the maximum vibration frequency f, F>2f, so as to ensure that the high-speed camera can clearly capture the test Track the motion state of point A;

[0080] (2) Take a strip 1b and the corresponding part of the bearing backing 1a from the water-lubricated rubber tail bearing 1 as the test piece 2 for testing (see figure 1 , figure 2 and image 3 ); Of course, two or more slats 1b can also be taken as test block 2;

[0081] (3) Mark the test tracking point A on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com