High-energy ignition coil

An ignition coil and high-energy technology, which is applied in the direction of engine ignition, ignition controller, electric spark ignition controller, etc., can solve the problems of large ignition energy and failure to provide it, and achieve the effect of improving energy conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

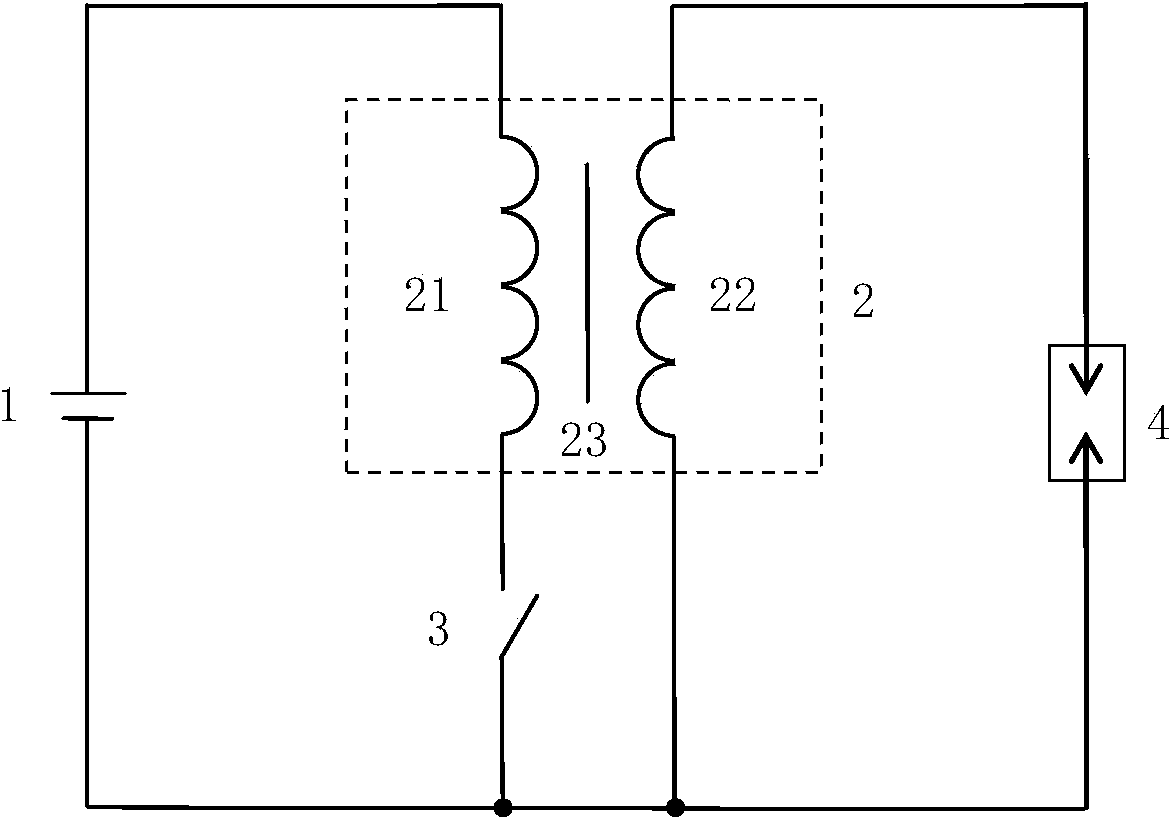

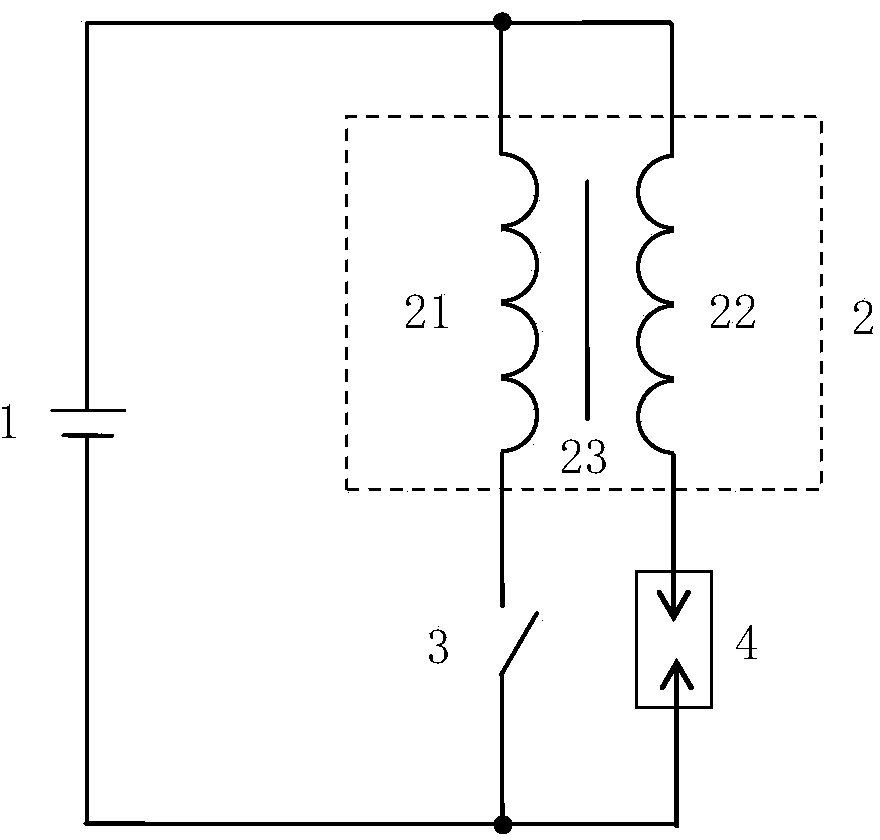

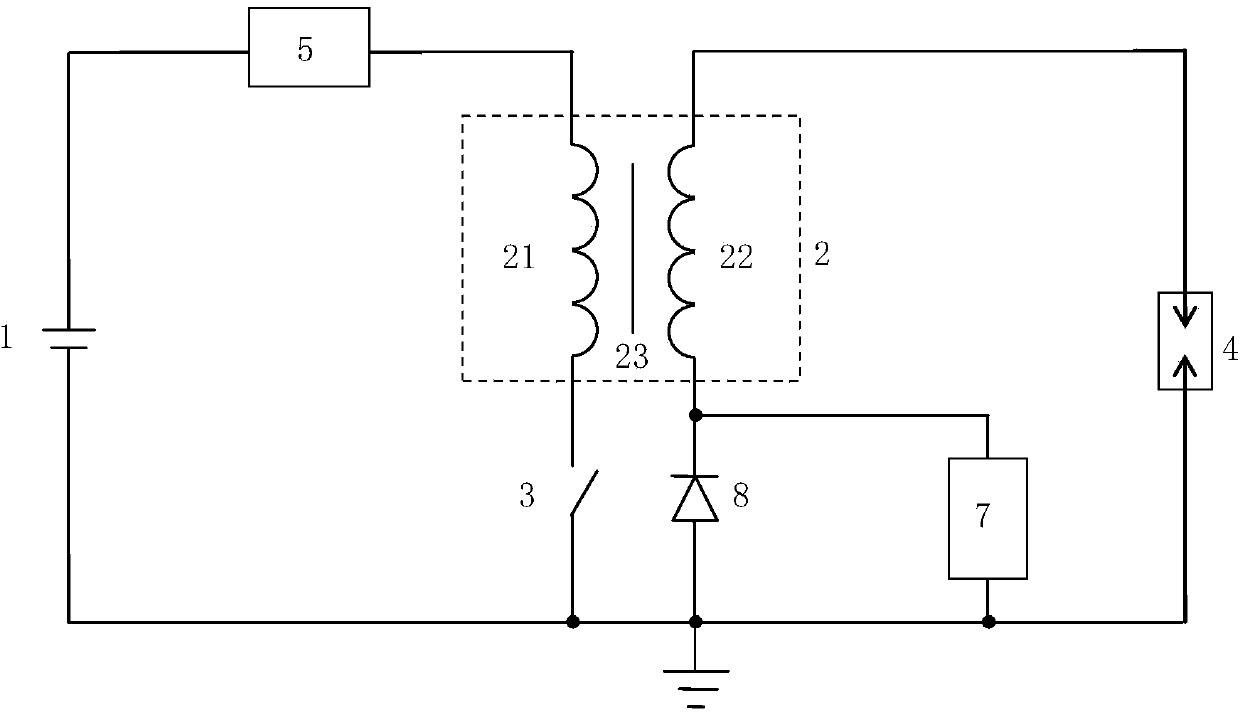

[0016] see Figure 1a and Figure 1b , the ignition energy value of the ignition coil Wherein T is the discharge time of the secondary coil 22 on the secondary coil circuit, u ISK-OUT is the ground pressure drop value of the end of the secondary coil 22 connected to the spark plug 4, i OUT is the value of the current through the secondary coil (i.e. the secondary current).

[0017] In the high-energy ignition coil of the present application, the discharge of the secondary coil 22 on the secondary coil circuit can be divided into two stages: the first stage is that the energy of the primary coil 21 is coupled to the secondary coil 22 to make the spark plug 4 conduct. The first stage is from time 0 to time T1 with a length of T1. The second stage is that the energy provided by the current maintaining device 7 turns on the spark plug 4 , and the second stage is from the time T1 to the time T1+T, and the length is T2. T=T1+T2. Therefore, the ignition energy value of the high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com