A compact two-way contact shrapnel structure

A contact shrapnel, compact technology, applied in the direction of contact parts, clamping/spring connection, etc., can solve the problems of cumbersome assembly, inability to meet the requirements of miniaturization and ultra-thinning of electronic products, inconvenient replacement, etc., and achieve maintenance and assembly. Convenience, small footprint, and stable installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following are the best examples of the structure of the compact bi-directional contact spring according to the present invention, which does not limit the protection scope of the present invention.

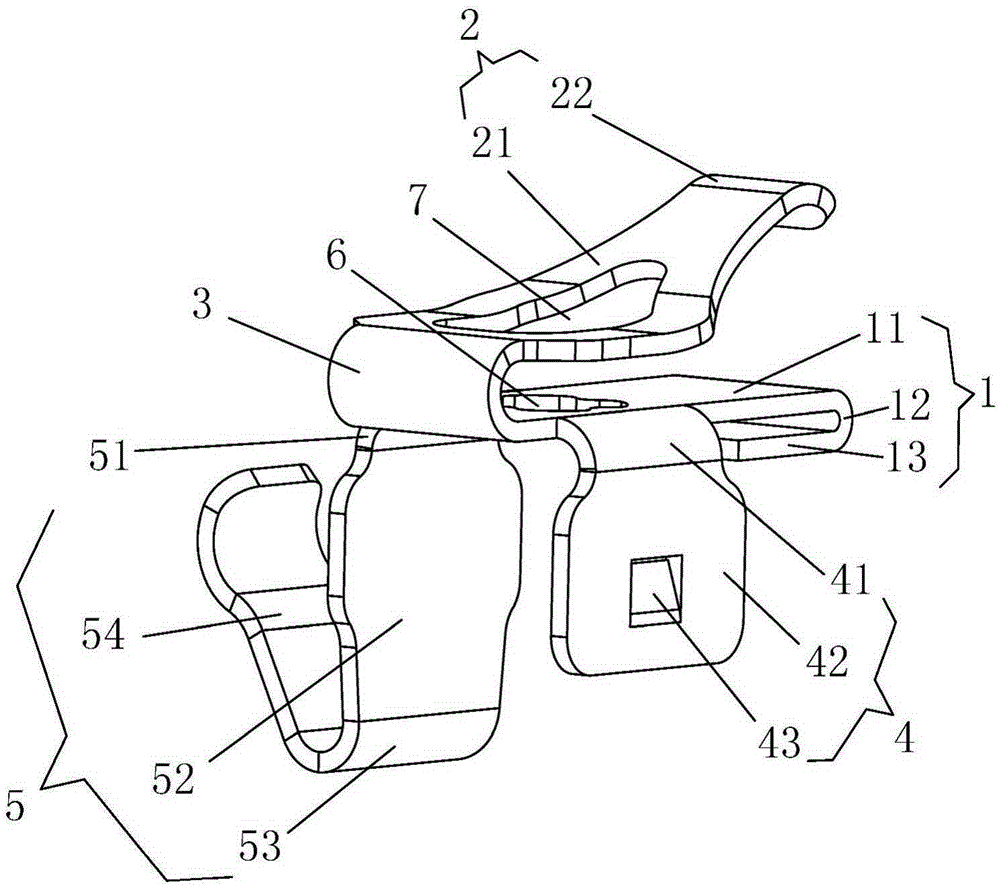

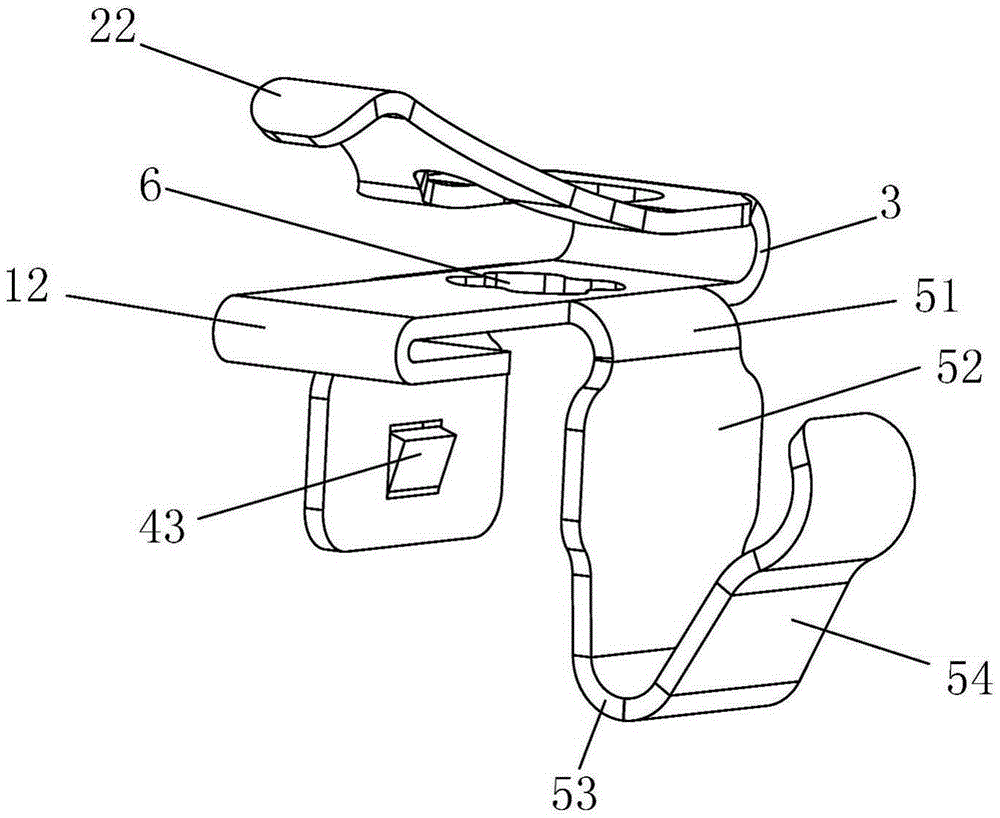

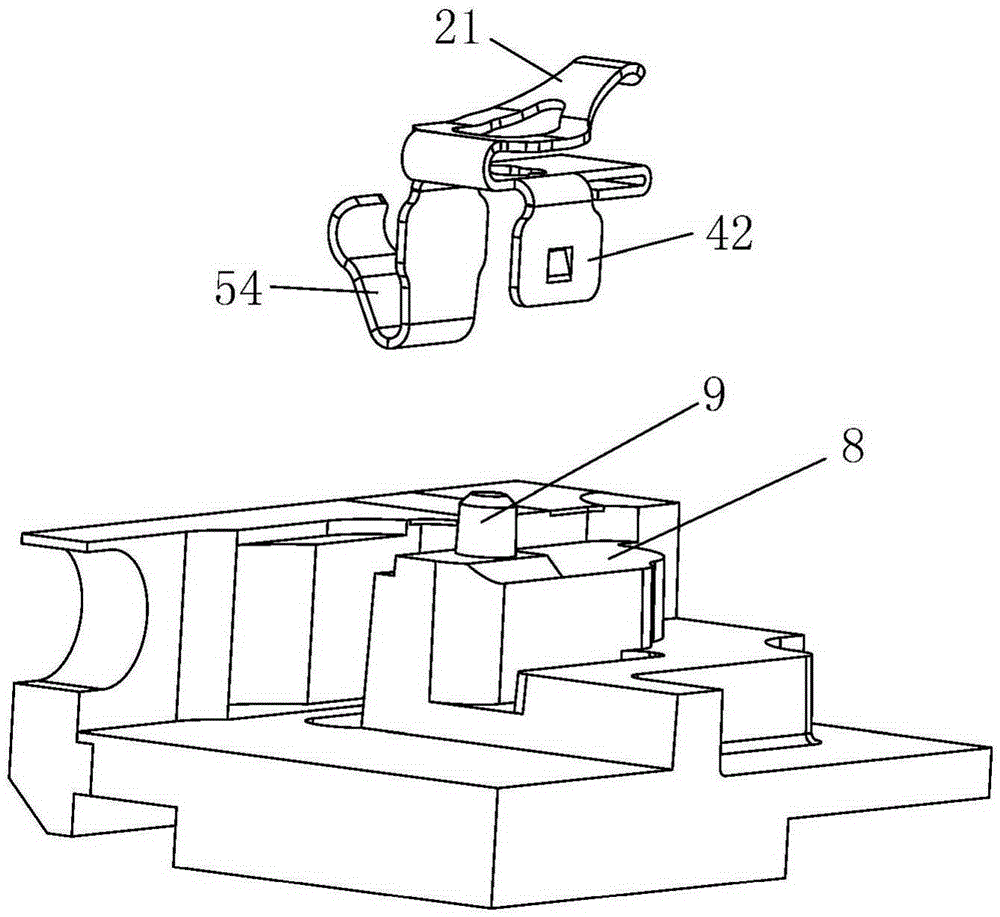

[0025] Please refer to figure 1 and figure 2 , the figure shows a compact two-way contact shrapnel structure, including the bottom mounting part 1, the elastic contact part 2, the elastic turning part 3, the side clamping part 4 and the side pressing part 5, the elastic turning part 3 consists of One end of the bottom mounting part 1 is reversely bent and formed, one end of the elastic contact part 2 is connected to the elastic turning part 3, the elastic contact part 2 is located above the bottom mounting part 1 and a gap is formed between the two, and the bottom mounting part 1 is opened There is a positioning hole 6 cooperating with the positioning column 9 of the fixing part 8, and the elastic contact part 2 is provided with a through hole 7 for the positioning co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com