A stator core ventilation ditch structure

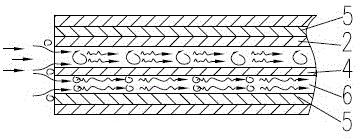

A stator core and ventilation ditch technology, which is applied to the shape/style/structure of the magnetic circuit and the static parts of the magnetic circuit, etc., can solve the problem of insufficient heat exchange between the cooling gas and the ventilation slots, and insufficient heat dissipation area of the ventilation slots. The cooling gas disturbance is not strong enough to improve the cooling effect, the overall structural strength is high, and the cooling effect is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

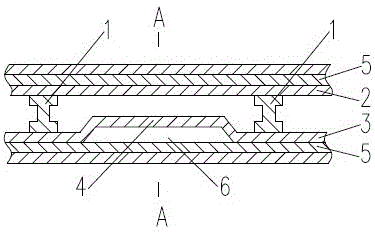

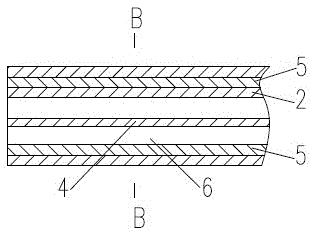

[0067] A stator core ventilation trench structure, including a plurality of repeating structural units, the repeating structural unit is formed by the channel surrounded by the upper ventilation slot piece 2, the lower ventilation slot piece 3 and two adjacent ventilation trench support components 1, the ventilation trench One end of the support member 1 is connected to the upper ventilation slot 2, and the other end is connected to the lower ventilation slot 3, and the upper ventilation slot 2 or the lower ventilation slot 3 has at least one protrusion 4 extending radially along the stator core , the protrusion 4 is located in the channel, the air channel 6 is formed between the protrusion 4 of the upper ventilation slot 2 and the stator core segment 5 adjacent to the upper ventilation slot 2, and the protrusion 4 of the lower ventilation slot 3 An air passage 6 is formed between the stator core segment 5 adjacent to the lower ventilation slot 3 , and the protrusion 4 separate...

Embodiment 2

[0070] A stator core ventilation trench structure, including a plurality of repeating structural units, the repeating structural unit is formed by the channel surrounded by the upper ventilation slot piece 2, the lower ventilation slot piece 3 and two adjacent ventilation trench support components 1, the ventilation trench One end of the support member 1 is connected to the upper ventilation slot 2, and the other end is connected to the lower ventilation slot 3, and the upper ventilation slot 2 or the lower ventilation slot 3 has at least one protrusion 4 extending radially along the stator core , the protrusion 4 is located in the channel, the air channel 6 is formed between the protrusion 4 of the upper ventilation slot 2 and the stator core segment 5 adjacent to the upper ventilation slot 2, and the protrusion 4 of the lower ventilation slot 3 An air passage 6 is formed between the stator core segment 5 adjacent to the lower ventilation slot 3 , and the protrusion 4 separate...

Embodiment 3

[0073] A stator core ventilation trench structure, including a plurality of repeating structural units, the repeating structural unit is formed by the channel surrounded by the upper ventilation slot piece 2, the lower ventilation slot piece 3 and two adjacent ventilation trench support components 1, the ventilation trench One end of the support member 1 is connected to the upper ventilation slot 2, and the other end is connected to the lower ventilation slot 3, and the upper ventilation slot 2 or the lower ventilation slot 3 has at least one protrusion 4 extending radially along the stator core , the protrusion 4 is located in the channel, the air channel 6 is formed between the protrusion 4 of the upper ventilation slot 2 and the stator core segment 5 adjacent to the upper ventilation slot 2, and the protrusion 4 of the lower ventilation slot 3 An air passage 6 is formed between the stator core segment 5 adjacent to the lower ventilation slot 3 , and the protrusion 4 separate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com