Screw-type piezoelectric type energy collector and preparation method thereof

An energy harvester, spiral technology, applied in piezoelectric devices/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, piezoelectric effect/electrostrictive or magnetostrictive motors, etc., It can solve the problems of insufficient low-frequency and wide-band, and achieve the effects of easy mass production, energy harvesting, and increased frequency bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is further described below in conjunction with embodiment. The scope of the present invention is not limited by these examples, and the scope of the present invention is set forth in the claims.

[0033] The specific steps of the helical low-frequency broadband piezoelectric energy harvester provided by the present invention and its preparation method are described below in conjunction with accompanying drawings 1-4.

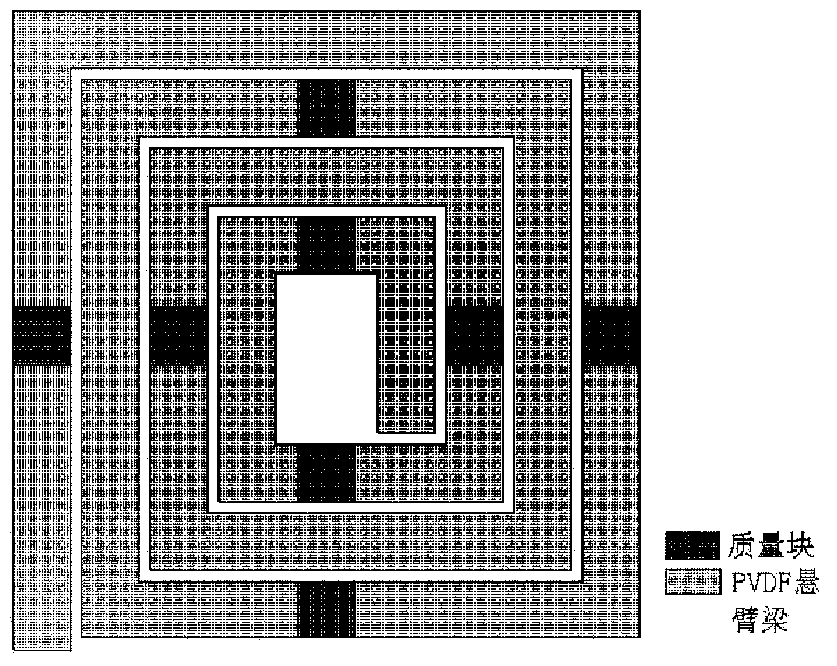

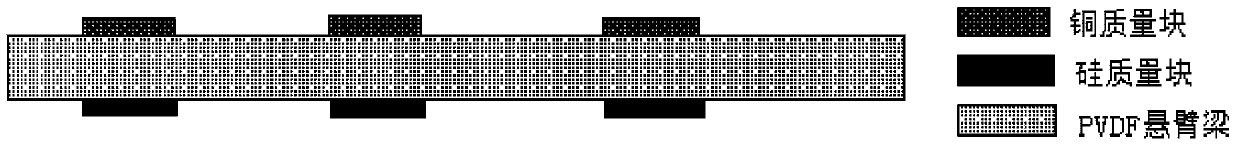

[0034] Referring to Fig. 1, Fig. 1(a) is a top view of the spiral energy harvester of the present invention. Fig. 1(b) is a schematic front view of the spiral piezoelectric energy harvester of the present invention. The structure of the energy harvester mainly includes: PVDF piezoelectric film, metal mass, and silicon mass. refer to figure 2 , figure 2 It is a scanning electron micrograph of the laser-cut PVDF film cantilever beam of the present invention. refer to image 3 , image 3 It is a microscope rendering of the electr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com