High-fidelity spot color number hard proofing method

A spot color and digital technology, applied in image communication, electrical components, etc., can solve the problems of high cost, long cycle, low efficiency, etc., and achieve the effect of high reproduction accuracy, strong applicability, and increased speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing.

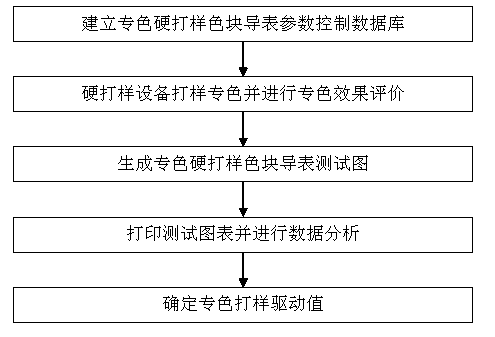

[0032] Such as figure 1 As shown, a high-fidelity spot color digital hard proofing method specifically includes the following steps:

[0033] Step 1. Establish a spot color hard proofing color block guide table parameter control database;

[0034] According to the proofing characteristics of hard proofing equipment at home and abroad, the position of different spot colors in the color gamut space and the control standard of color difference of spot color hard proofing data, set the parameter control database of the color block guide table of spot color hard proofing.

[0035] Step 2. Proof the spot color with hard proofing equipment and evaluate the effect of the spot color

[0036] 2-1. Utilize printing general color management software to control hard proofing equipment for spot color proofing;

[0037] 2-2. After the spot color proofing sheet is completed and dried, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com