Angle workbench

An angle workbench and workbench technology, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve problems such as complex structures, and achieve the effects of quick installation, shortened working hours, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

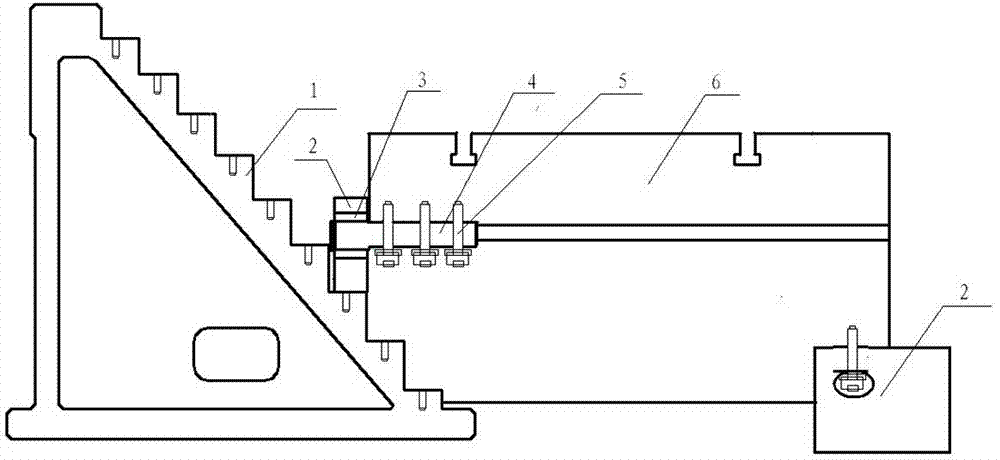

[0011] figure 1 As shown, it is an angle workbench, including a workbench 6, one end of the workbench 6 is fixed on the first fixing base 20 through a screw assembly 5, and the other end of the workbench 6 is passed through the guide post 4 and the guide post in turn. The sleeve 3 is fixed on the second fixing base 21, and the second fixing base 21 is fixed on the triangular support 1 through a screw assembly. Wherein, T-shaped slots 7 for clamping workpieces are uniformly distributed along the transverse direction on the table surface of the worktable 6 . Wherein, one end of the guide post 4 is fixed on the workbench 6 through a screw assembly 5 , and the other end passes through the guide sleeve 3 ; and a clearance fit is adopted between the guide post 4 and the guide sleeve 3 . Wherein, the guide sleeve 3 is installed in the second fixing seat 21 in the form of interference fit.

[0012] In addition, the triangular bracket 1 has multiple steps with different sinusoidal an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com