Device and method for removing cyan wax on outer surface of bamboo

An outer surface and bamboo technology, which is applied to a process of increasing surface roughness, bamboo green surface treatment, and bamboo green wax removal from the outer surface of bamboo materials, which can solve the problems of large cutting amount of bamboo green, tool wear and high energy consumption. , to achieve the effect of increasing roughness, saving raw materials and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example

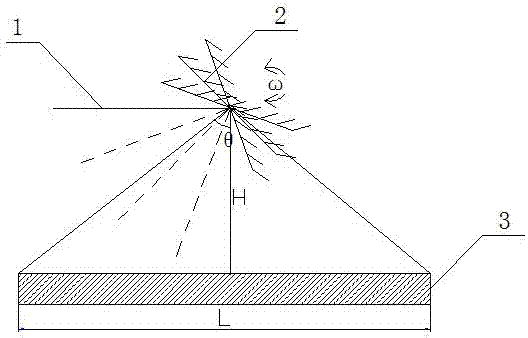

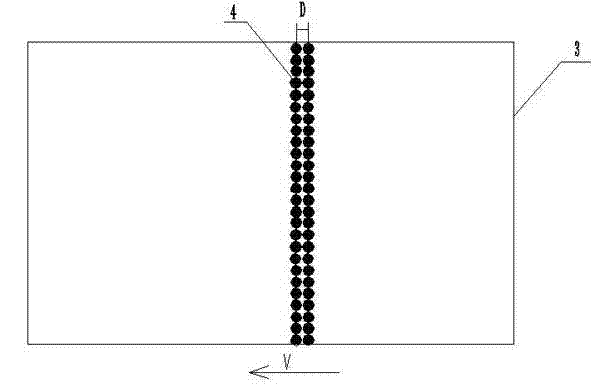

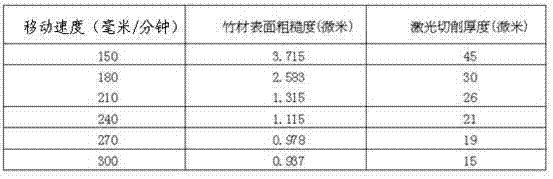

[0027] Test example: The laser power emitted by the laser generator is 10 watts, the laser type is RF carbon dioxide laser, the laser modulation frequency is 20KHz, the laser spot diameter is 0.2mm, the reciprocating swing frequency of the galvanometer 2 is 84 radians / min, and the distance between the rotation axis of the galvanometer 2 The distance of the bamboo slice 3 is 160 mm, and the bamboo slice sample is 30 mm wide and 6 mm thick. The surface roughness is 0.113 microns without laser treatment. The bamboo slices pass through the processing system at 150 mm / min, 180 mm / min, 210 mm / min, 240 mm / min, 270 mm / min, and 300 mm / min. The cutting thickness and surface roughness are measured by a profiler. The roughness uses the contour arithmetic mean deviation Ra, as shown in Table 1:

[0028] Table 1 Laser-treated bamboo surface roughness and thickness at different moving speeds

[0029]

[0030] It can be seen from the above table that when the laser power is constant, the laser c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com