Full-automatic hydraulic deep embossing machine

A fully automatic, hydraulic mechanism technology, applied in the direction of machining/deformation, etc., can solve the problems of increased machine noise and vibration, without any safety protection measures, etc., to reduce impact sound and vibration, improve work efficiency, and improve work speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Further illustrate by embodiment below:

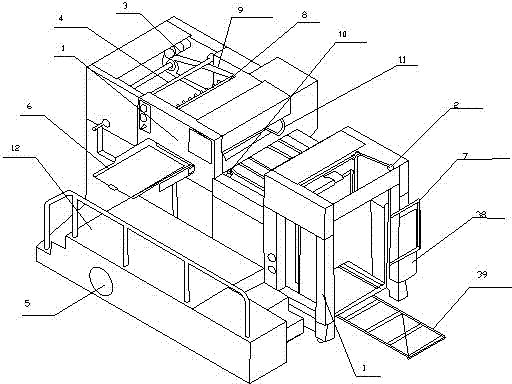

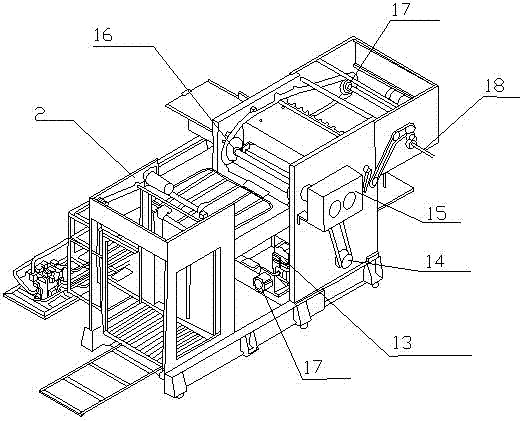

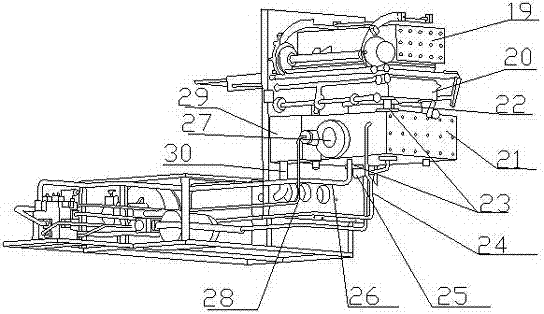

[0016] Such as Figure 1~4 As shown, a fully automatic hydraulic deep embossing machine is composed of a frame 1, a paper conveying mechanism 2, a main machine 3, a paper receiver 4, a hydraulic mechanism, a cooler 5, and a plate frame 6. The paper conveying mechanism 2, The host machine 3 and the paper receiver 4 are arranged on the frame 1 in sequence, the plate frame 6 is installed on one side of the host machine 3, the hydraulic mechanism is installed on the same side as the plate frame 6 and a pedal 12 is set on the hydraulic mechanism; the host machine includes an upper template 19. Lower formwork 20, oil cylinder base 21, main oil cylinder 22, small oil cylinder 23, upper formwork 19 and frame 1 on both sides are fixed, the middle of lower formwork 20 is connected with main oil cylinder 22, and small oil cylinder 23 is connected with four corners of lower formwork 20 , the small oil tank 29 is connected to the hydraulic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com