Advanced Treatment of Textile Dyeing and Finishing Wastewater by Fenton Fluidized Bed-ibac

A technology for textile dyeing and finishing and advanced treatment, applied in textile industry wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Biochemical treatment, poor standard reliability and stability, etc., to achieve the effect of improving biological treatment efficiency, significant economic benefits, and ensuring effluent water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] In the comprehensive wastewater of a textile dyeing and finishing enterprise, the COD of the raw water is about 1000mg / L, the chroma is about 100 times, the SS is about 200mg / L, and the pH is about 8.5. After the secondary treatment, the COD of the biochemical treatment effluent is about 200mg / L, the pH is about 7.5, the chroma is about 80 times, and the SS is about 80mg / L.

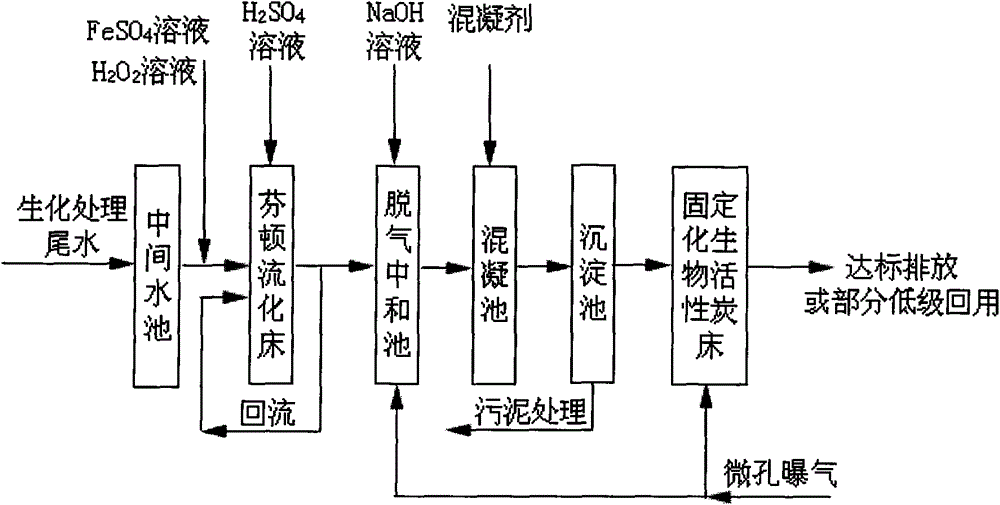

[0035] use figure 1 The treatment process includes the following steps:

[0036] (1) The tail water of the biochemical treatment of textile dyeing and finishing wastewater enters the intermediate pool, and is pumped into the Fenton fluidized bed through the water inlet pump, and H is added to the Fenton fluidized bed through the dosing system. 2 SO 4 solution, FeSO 4 solution and H 2 o 2 solution, through the reflux pump to reflux part of the effluent from the Fenton fluidized bed to make the Fenton fluidized bed in a fluidized state, and remove most of the COD, organic dyes and additives in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com