A kind of glycine functional ionic liquid and its preparation method and application

A glycine, ionic liquid technology, applied in separation methods, chemical instruments and methods, educts, etc., can solve problems such as slow absorption rate, achieve high-efficiency absorption capacity, improve stability, and facilitate industrialization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1: the synthesis of aminoacetic acid functional ionic liquid

[0043] The first step is the synthesis of 1-hydroxyethyl-3-methylimidazole chloride.

[0044] The specific reaction formula of the first step is as follows:

[0045]

[0046] Put the 250mL round-bottomed three-necked flask into an oil bath, install a condensation reflux device, and feed the raw materials N-methylimidazole (0.4mol) and 2-chloroethanol (0.6mol) into the three-necked flask according to the molar ratio of 1:1.5 Add in, turn on the magnetic stirring, raise the temperature to 80°C, and react for 24 hours; after the reaction, use a rotary evaporator to distill under reduced pressure to remove unreacted raw materials in the ionic liquid, and cool and crystallize at room temperature at 25°C; wash the crystals with ethyl acetate for 3 Filtration after the second time; put the ionic liquid containing a trace amount of solvent into a vacuum drying oven, set the temperature at 70°C and dry...

Embodiment 2

[0051] Embodiment 2: Glycine functional ionic liquid is used as absorbent

[0052] 0.1mol[C 2 OHmim][Gly] was dissolved in deionized water, and the volume was fixed to a 250mL volumetric flask with deionized water, and stirred evenly to obtain an absorption solution containing glycine functional ionic liquid. The obtained absorption solution containing glycine functional ionic liquid was placed in a constant temperature water tank at 30° C. for 10 minutes, so that the temperature of absorption liquid containing glycine acid functional ionic liquid reached the set temperature of 30° C., stirred and mixed, and set aside.

Embodiment 3

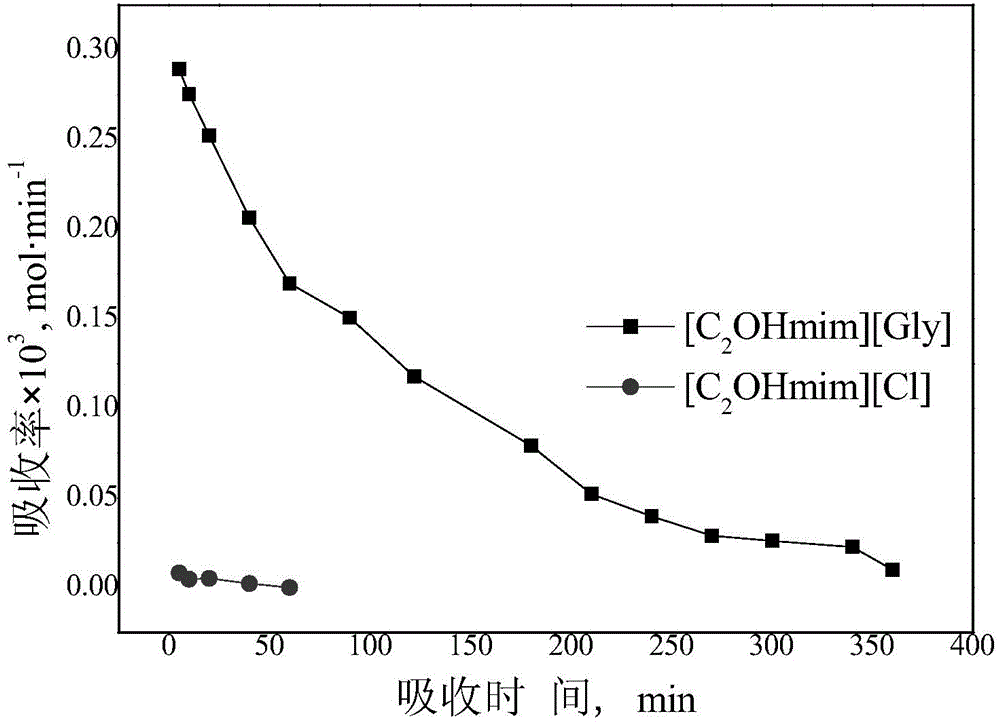

[0057] Embodiment 3: Glycine functional ionic liquid is to CO 2 The absorption effect

[0058] The absorbing solution containing aminoacetic acid functional ionic liquid prepared in embodiment 2 and the absorbing solution containing chlorinated 1-hydroxyethyl-3-methylimidazole prepared in comparative example 1 are tested respectively according to the following methods for absorbing capacity of carbon dioxide:

[0059] The absorption process is carried out in double stirred tanks, normal pressure (101KPa), temperature 30°C, CO 2 The flow rate is 50mL / min, the total gas flow rate is 0.5L / min, the volume of the absorption liquid is 250mL, and the concentration of the absorbent is 0.4mol / L. The gas phase stirring speed of the double stirred tank is controlled to 250rpm, and the liquid phase stirring speed is 100rpm. Gas import and export CO 2 The concentration was detected by gas chromatography. When the inlet and outlet concentrations are basically the same, the absorption sat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cycle efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com