Hydrophobic molecular sieve runner and preparation method thereof

A molecular sieve and hydrophobic technology, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve problems such as inability to efficiently separate carbon dioxide, and achieve the effect of high-efficiency carbon dioxide absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

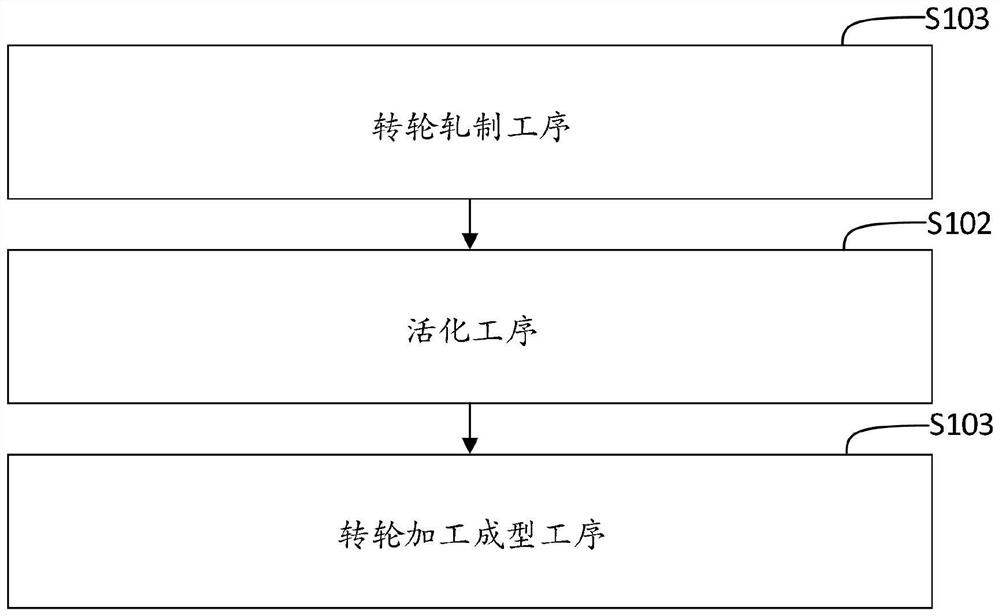

[0029] figure 1 A schematic flow chart of the preparation method of the hydrophobic molecular sieve runner in this embodiment is shown, and the method includes steps S101-S103:

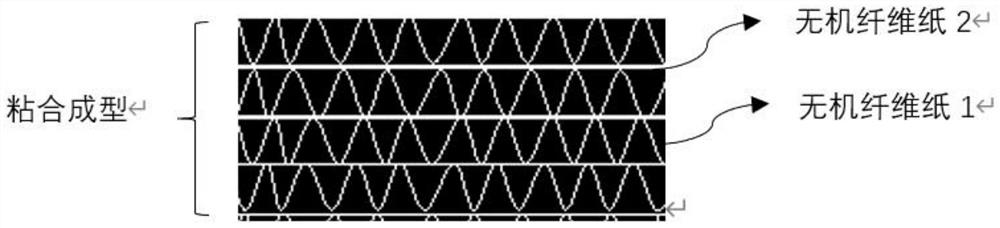

[0030] S101 runner rolling process, the inorganic fiber paper passes through the molecular sieve slurry at a uniform speed, after drying, it is impregnated in the inorganic glue and then formed by hot pressing to form corrugated paper, and another layer of inorganic fiber base paper coated on the molecular sieve is impregnated and dried in the inorganic glue Finally, it is bonded with the corrugated paper to form a honeycomb body, and dried to obtain the primary body of the runner.

[0031] S102 Activation process, placing the primary body of the runner in a high-temperature furnace for 1-8 hours and calcining at a temperature of 200-800°C.

[0032] S103 The process of processing and forming the runner, performing hydrophobic treatment on the primary body of the runner, and assembling the hydrophobic...

Embodiment 2

[0039] wheel rolling process,

[0040] Wheel rolling process: pass the first inorganic fiber paper and the second inorganic fiber paper through the molecular sieve slurry with a mass fraction of 15% and a viscosity of 10mpa·s at 1m / s, dry, and then pass the first inorganic fiber paper and the second inorganic fiber paper is soaked in sodium silicate, the first inorganic fiber paper is hot-pressed at 35°C to obtain a corrugated paper with a flute height of 1.5 mm, and the second inorganic fiber paper and the Bond to form a honeycomb body, and dry it under the environment of 60°C to obtain the primary body of the runner.

[0041] Activation process: placing the primary runner body in a high-temperature furnace for 1-8 hours and calcining at a temperature of 200-800°C;

[0042] Runner processing and forming process: performing hydrophobic treatment on the primary body of the runner, and assembling the hydrophobic molecular sieve runner;

[0043] Pass the inorganic fiber paper t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com