Dye sensitized solar cell and preparation method thereof

A solar cell, dye sensitization technology, applied in the field of titanium dioxide nanotube dye-sensitized solar cells and its preparation, can solve the problems of accelerating anatase transformation, not conducive to obtaining stable anatase phase nanotube array films, and affecting , to achieve high-efficiency absorption capacity, improve energy conversion efficiency, and reduce the effect of recombination probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

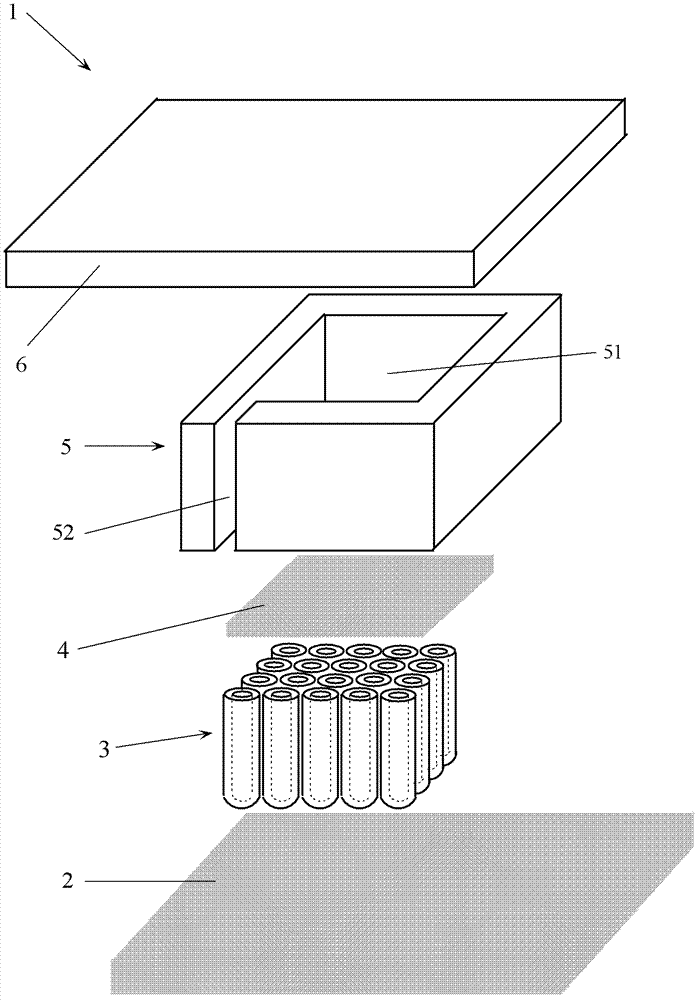

Image

Examples

Embodiment 1

[0046] In this embodiment, the preparation method of anatase titanium dioxide nanotubes with high crystallization, ordering and structural stability comprises the following steps:

[0047] (1) Cut the high-purity Ti sheet into small pieces of 20mm×10mm;

[0048] (2) Clean the small pieces obtained in step (1) ultrasonically in acetone for 15 minutes, then ultrasonically clean them in absolute ethanol for 15 minutes, and finally rinse them with deionized water for 3 to 5 times, and place the cleaned Ti pieces in a drying oven Dry and reserve;

[0049] (3) Weigh 5.55gNH 4 Dissolved in 15ml deionized water, stirred with a magnetic stirrer for 15min to make NH 4 F is completely dissolved, and then mixed with 485ml formamide to obtain an electrolyte;

[0050] (4) Under room temperature conditions, the Ti sheet is immersed in the electrolyte solution configured in step (3) as the anode, and the platinum sheet of the same size is used as the cathode for the counter electrode, and ...

Embodiment 2

[0056] In this embodiment, the preparation method of single-phase anatase nanotubes comprises the following steps:

[0057] Steps (1) to (7) are the same as Embodiment 1, and step (8) is: peeling off the TiO 2 The nanotube array thin film precursor is placed in a porcelain ark, covered with a porcelain ark of the same size, and then annealed in a tube furnace. In this embodiment, the annealing temperature is 750°C, the holding time is 1h, the annealing atmosphere is 99.99% high-purity oxygen atmosphere, the heating rate is 1°C / min, and the cooling rate is 5°C / min.

Embodiment 3

[0059] In this embodiment, the preparation method of single-phase anatase nanotubes comprises the following steps:

[0060] Step (1)~step (7) is identical with embodiment 1, and step (8) is: the TiO after peeling off 2 The nanotube array thin film precursor is placed in a porcelain ark, covered with a porcelain ark of the same size, and then annealed in a tube furnace. In this embodiment, the annealing temperature is 800°C, the holding time is 1h, the annealing atmosphere is 99.99% high-purity oxygen atmosphere, the heating rate is 1°C / min, and the cooling rate is 5°C / min.

[0061] In the preparation method of anatase titanium dioxide nanotubes with high crystallization, ordering and structural stability of the present invention, the TiO prepared by anodic oxidation 2 The nanotube array film precursor was exfoliated from the Ti sheet substrate, which successfully eliminated the "phagocytosis effect" of the Ti substrate during the annealing process and the resulting TiO 2 Str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com