Electromagnetic wave radiation resistant optical cement and preparation method thereof

An anti-electromagnetic wave and optical glue technology, applied in the field of optical glue, can solve the problems of uneven dispersion of optical glue, difficulty in satisfying users, weak anti-electromagnetic radiation performance, etc., to achieve high-efficiency anti-electromagnetic radiation, avoid weak stability, The effect of high absorbency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

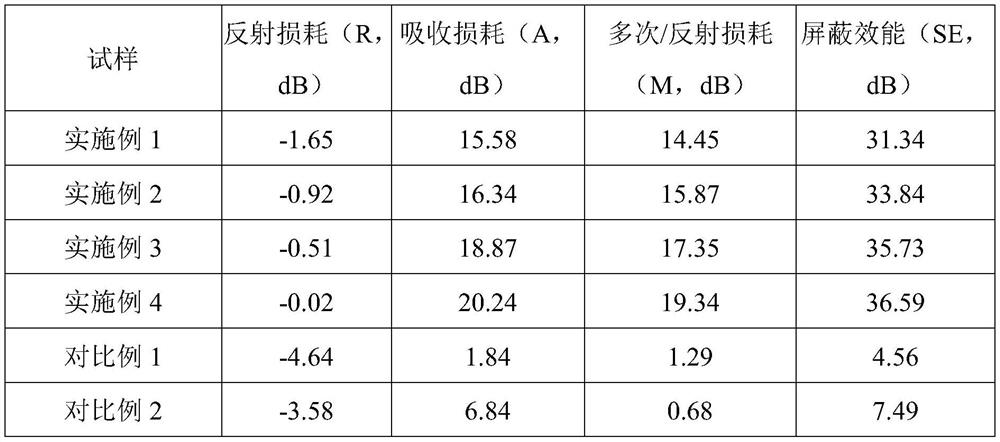

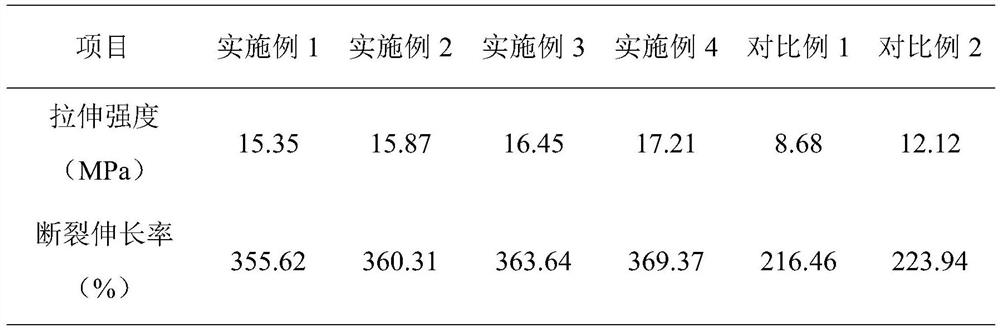

Examples

Embodiment 1

[0025] An optical glue for preventing electromagnetic wave radiation and a preparation method thereof, comprising the following steps:

[0026] (1) Add 0.4g graphene oxide to 50ml deionized water, ultrasonically treat for 2h, disperse evenly to obtain a suspension, and add 5gNaOH and 9gClCH under constant stirring 2 COOH, after the dropwise addition, the ultrasonic treatment time is 3h, and the mixture is dialyzed against water for 45h, and then the dispersion is filtered with filter paper. After a large number of graphene sheets pass through the filter paper, the filtrate is collected and the solvent is evaporated to dryness with a rotary evaporator. , after drying in an oven at 60°C for 12 hours, carboxylated graphene was obtained;

[0027] (2) 1g boron block, 39gFeCl 2 4H 2 O and 47gCoCl 2 ·6H 2 O was dissolved in 100ml of deionized water, 18g of polyacrylic acid was added to the solution, and after adding 10g of 0.1M sodium hydroxide solution, a black solution was form...

Embodiment 2

[0032] An optical glue for preventing electromagnetic wave radiation and a preparation method thereof, comprising the following steps:

[0033] (1) Add 0.5g graphene oxide to 50ml deionized water, ultrasonically treat for 2h, disperse evenly to obtain a suspension, and add 5gNaOH and 9.5gClCH under constant stirring 2 COOH, after the dropwise addition, the ultrasonic treatment time is 3.2h, and the mixture is dialyzed against water for 46h, and then the dispersion is filtered with filter paper, and after a large number of graphene sheets pass through the filter paper, the filtrate is collected and evaporated to dryness with a rotary evaporator Solvent, obtain carboxylated graphene after drying in 60 ℃ oven for 14h;

[0034] (2) 1.2g boron block, 39.5gFeCl 2 4H 2 O and 47.2 g CoCl 2 ·6H 2 Dissolve O in 100ml deionized water, add 20g polyacrylic acid into the solution, add 10g 0.1M sodium hydroxide solution, stir well and form a black solution, grow at 80°C for 30min, dry in...

Embodiment 3

[0039] An optical glue for preventing electromagnetic wave radiation and a preparation method thereof, comprising the following steps:

[0040] (1) Add 0.6g graphene oxide to 50ml deionized water, ultrasonically treat for 2h, disperse evenly to obtain a suspension, and add 5gNaOH and 10gClCH under constant stirring 2 COOH, after the dropwise addition, the ultrasonic treatment time is 4h, and the mixture is dialyzed against water for 47h, and then the dispersion is filtered with filter paper. After a large number of graphene sheets pass through the filter paper, the filtrate is collected and the solvent is evaporated to dryness with a rotary evaporator. , after drying in an oven at 60°C for 16 hours, carboxylated graphene was obtained;

[0041] (2) 1.2g boron block, 39.5gFeCl 2 4H 2 O and 47.5 g CoCl 2 ·6H 2 Dissolve O in 100ml deionized water, add 23g polyacrylic acid into the solution, add 10g 0.1M sodium hydroxide solution, stir well and form a black solution, grow at 80...

PUM

| Property | Measurement | Unit |

|---|---|---|

| release force | aaaaa | aaaaa |

| release force | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com