Fracturing truck and fracturing equipment set

A technology for fracturing trucks and fracturing pumps, which is applied in mechanical equipment, liquid variable volume machinery, and production fluids, etc., can solve the problems of expensive components, high cost of fracturing trucks, and affect the progress of operations, and reduce manufacturing costs. and production difficulty, reduce the difficulty of component selection, and improve the effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

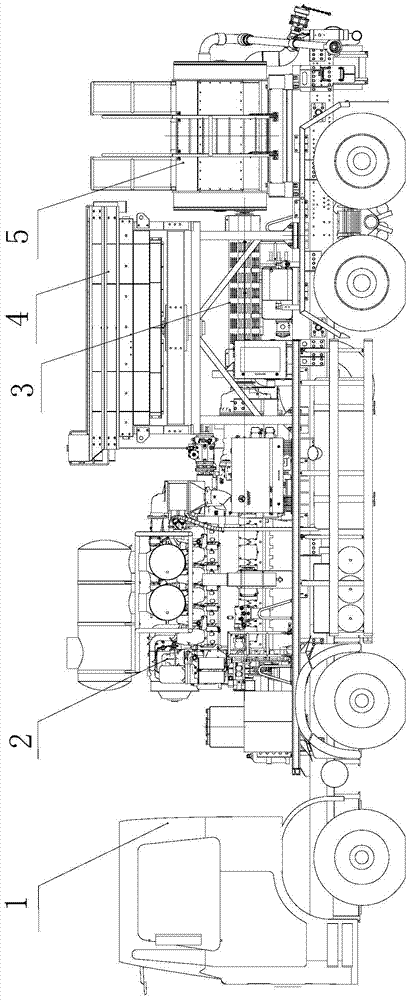

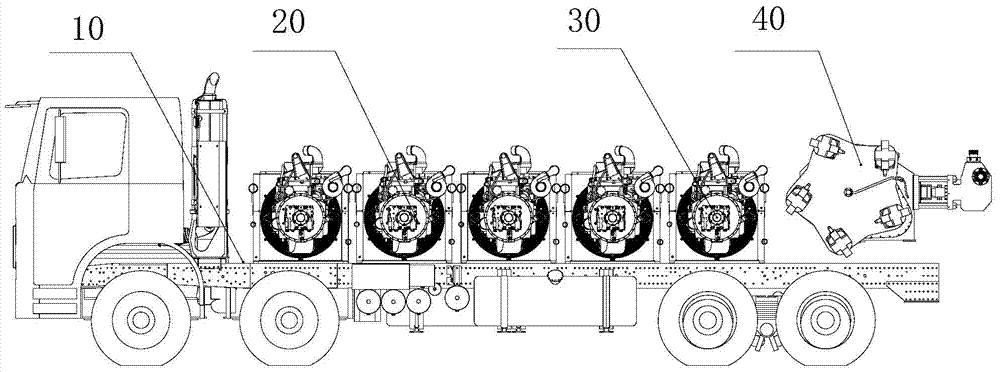

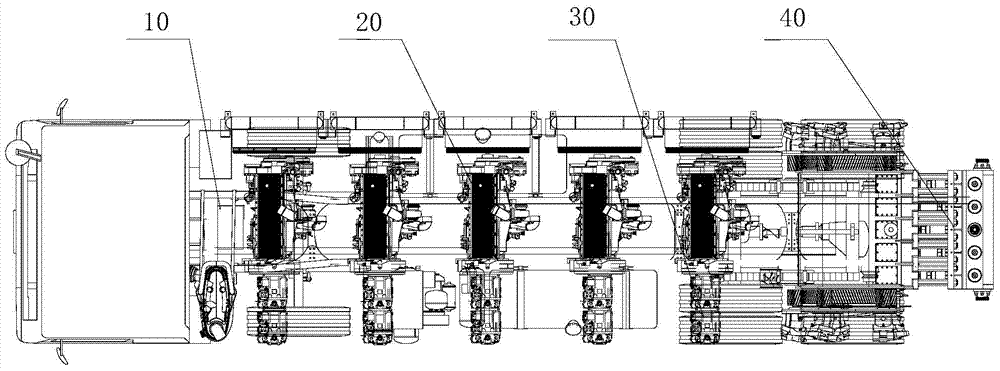

[0066] refer to figure 2 and Figure 4 , which shows components such as the power system and transmission system of the fracturing vehicle in this embodiment. In this embodiment, the booster mechanism of the fracturing vehicle can use a fracturing pump 40 , and the transmission system 30 can include an oil pump 31 and a motor 34 . Wherein, at least two engines 20 are connected in parallel to output power, and each engine 20 drives at least one oil pump 31 matched therewith, and the oil pump 31 is connected with a hydraulic oil tank 32 . The oil pump 31 is connected with at least one motor 34 to provide pressure oil for the at least one motor 34 . The motor 34 is connected to the fracturing pump 40 and drives the fracturing pump 40 .

[0067] In this embodiment, multiple diesel engines with medium and small power can be used as the power source, and multiple diesel engines work in parallel to drive the fracturing pump simultaneously, wherein the sum of engine power is not l...

Embodiment 2

[0084] refer to Figure 5 , which shows components such as the power system and transmission system of another fracturing vehicle provided in this embodiment. Different from the above-mentioned first embodiment, the configuration and layout of the transmission system of this embodiment can be adopted in the following manner:

[0085] Such as Figure 5As shown, the booster mechanism of this embodiment can use a hydraulic cylinder 50 and a booster cylinder 60 , and the transmission system 30 can include an oil pump 31 , a hydraulic oil tank 32 and a control valve group 36 . In this embodiment, at least two engines 20 are connected in parallel to output power, and each engine 20 drives at least one oil pump 31 matched therewith. The oil pump 31 is connected with a hydraulic oil tank 32 and at least one control valve group 36 . The control valve group 36 is connected between the oil pump 31 and the hydraulic oil cylinder 50 , and the control valve group 36 is used to control th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com