Direct-acting-valve engine

A technology for engines and direct-acting valves, applied to engine components, machines/engines, lift valves, etc., can solve problems such as complex mechanisms and pollution, and achieve high reliability, low manufacturing costs, and simple structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

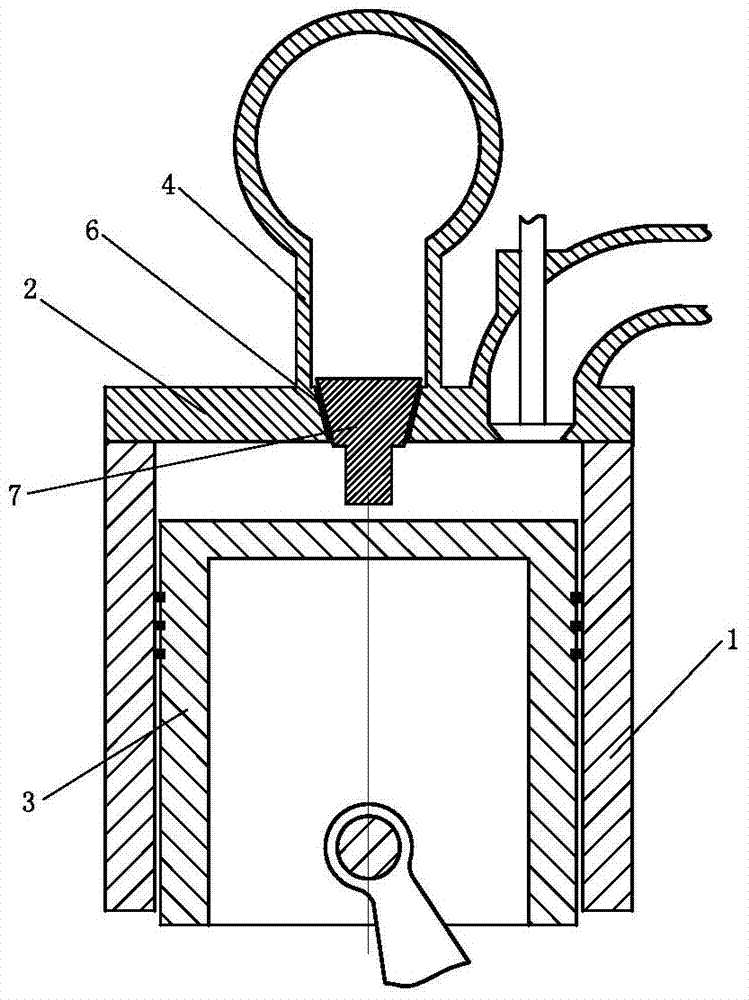

[0058] like figure 1 The shown direct-acting valve engine includes a cylinder 1, a cylinder head 2, a piston 3 and a pipeline 4, the cylinder 1 is connected to the cylinder head 2, the piston 3 is arranged in the cylinder 1, and the pipeline 4 Connected with the cylinder head 2, the connection between the pipeline 4 and the cylinder head 2 is provided on the cylinder head 2 to communicate with the pipeline 4 and the cylinder 1. A valve body 7 is arranged there, and the valve body 7 cooperates with the seat port 6, and the valve body 7 is controlled by the piston 3 to open and close the seat port 6 according to a timing relationship.

Embodiment 2

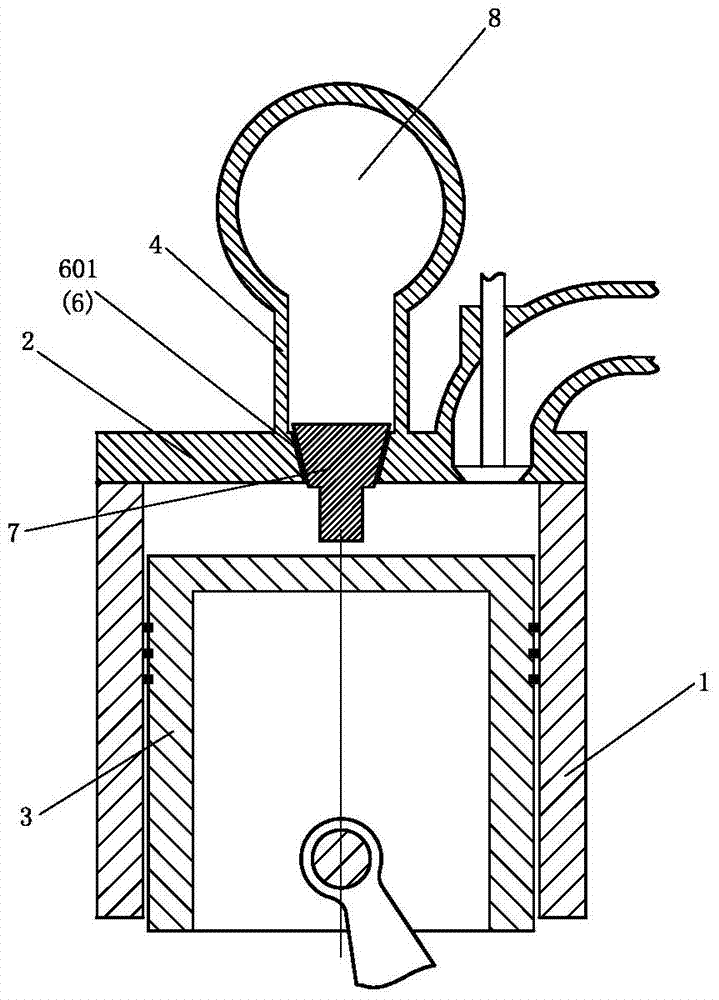

[0060] like figure 2 The difference between the shown direct-acting valve engine and Embodiment 1 is that the direct-acting valve engine also includes a high-pressure working medium source 8, and the seat port 6 is set as an outwardly opened seat port 601, and the high-pressure working medium source 8 communicates with the pipeline 4, and the high-pressure working medium in the high-pressure working medium source 8 is quantitatively introduced into the cylinder 1 through the outer opening 601 according to the timing relationship, no longer undergoes combustion chemical reaction, and directly expands to push the Described piston 3 works externally.

Embodiment 3

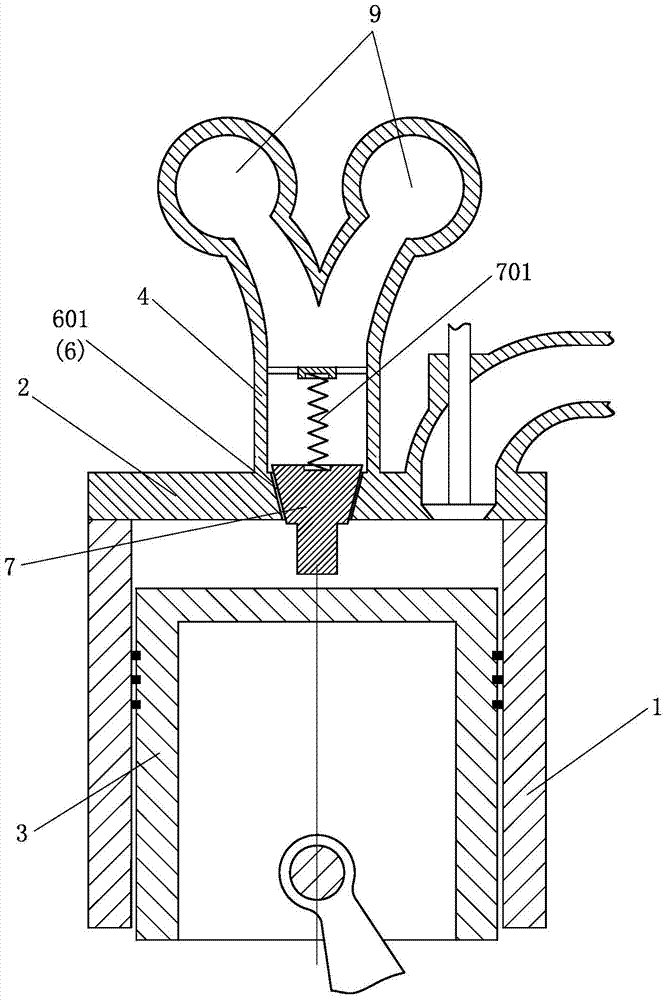

[0062] like image 3 The difference between the shown direct-acting valve engine and Embodiment 1 is that the direct-acting valve engine also includes a high-pressure source of working fluid 9, and the seat port 6 is set as an outwardly opened seat port 601. In the valve body 7 is provided with a closing elastic body 701, the high-pressure working medium source 9 is connected to the pipeline 4, and the high-pressure working medium in the high-pressure working medium source 9 is drawn by the outer opening 601 according to the timing relationship. Quantitatively introduced into the cylinder 1, after the combustion chemical reaction, the piston 3 expands to push the piston 3 to do work.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com