Inlet and outlet base of multistage centrifugal pump

A centrifugal pump, water inlet and outlet technology, applied in the field of centrifugal pumps, can solve the problems of waste of resources, human and financial resources, large environmental impact, and high cost investment, and achieve the effect of reducing cost investment, excellent sealing performance, and removing pollution problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

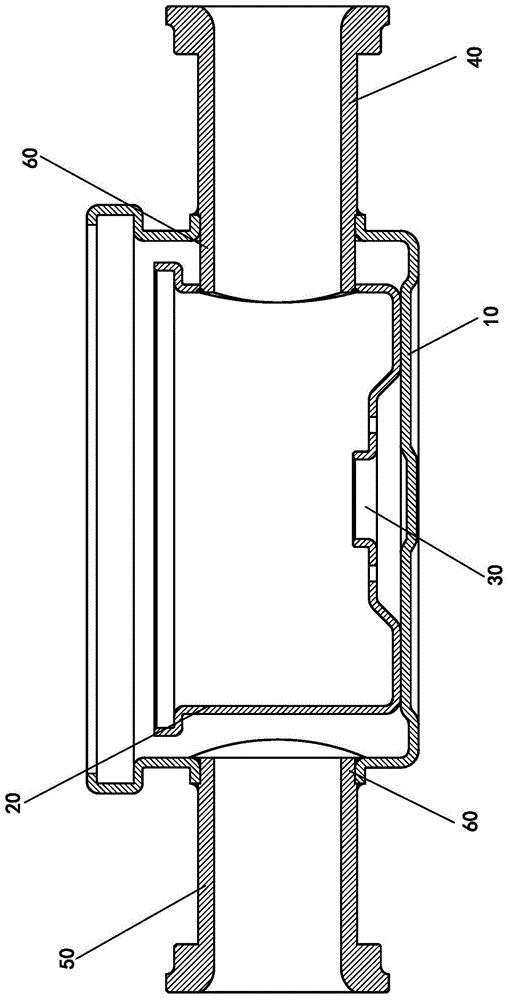

[0031] Such as figure 1 As shown, it is a water inlet and outlet base of a multistage centrifugal pump disclosed in the present invention. The side wall of the outer casing 10 is provided with a water inlet hole and a water outlet hole, and an inner cylinder body 20 is welded in the cavity of the outer casing 10. The side wall of the cylinder body 20 is provided with a water inlet hole corresponding to the position of the water inlet hole of the outer casing 10, the upper ends of the outer casing 10 and the inner cylinder body 20 are provided with openings, and the middle part of the bottom surface of the inner cylinder body 20 is provided with a shaft. hole 30, the water inlet pipe 40 is welded and fixed on the water inlet hole of the outer casing 10 and the inner cylinder body 20, and the water outlet pipe 50 is welded and fixed on the water outlet hole of the outer casing 10, and the outer casing 10 and the inner cylinder body 20 Water gaps are arranged between the side wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com