Permanent magnet bearing and roller bearing combined bearing

A roller and bearing technology, applied in the field of mechanical parts, can solve the problems of loss of stability, high processing, assembly, and installation process requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

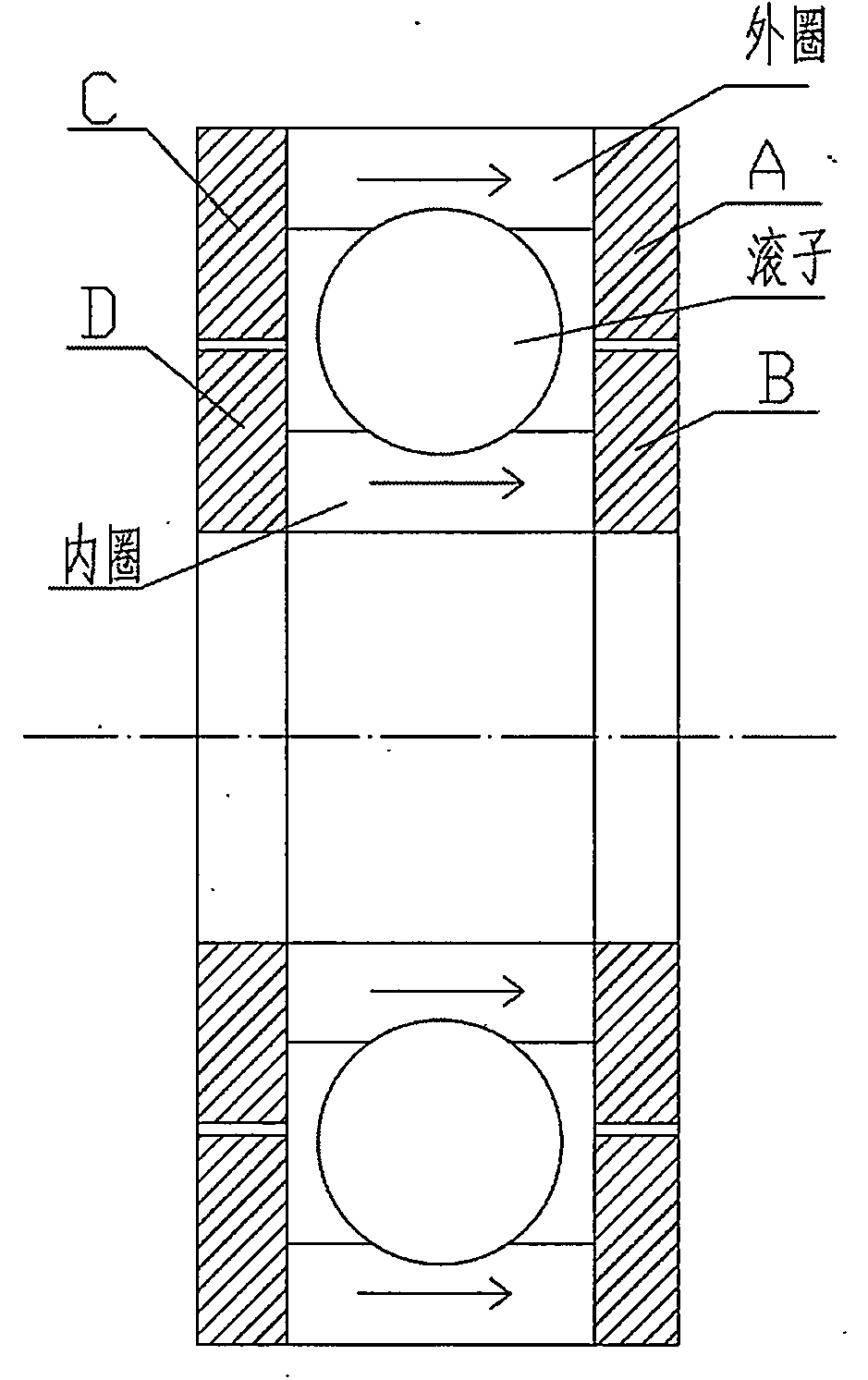

[0006] Such as figure 1 As shown, rollers are installed between the inner and outer rings like ordinary roller bearings to form a commonly used roller bearing; since the outer ring and inner ring are both processed by permanent magnetic steel, and both are axially magnetized , the same magnetic direction, coaxial arrangement, the same axial length, aligned up and down, the magnetic force lines of the inner and outer ring magnets are all concentrated to the magnetizer A through the magnetizers A, B, C, and D located on both sides of the inner and outer rings and the gap between B, C and D; due to the mutual repulsion of the same poles, the inner and outer rings repel each other, forming a radial permanent magnetic bearing. The repulsive force between the inner and outer rings reduces the extrusion force of the inner and outer rings of the roller bearing on the rollers, thereby reducing friction, wear, vibration and noise of the system, increasing the speed of the bearing, and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com