Valve

A valve and spool technology, applied in the field of low-torque and low-friction valves, can solve the problems of spool damage, difficulty in obtaining balanced pre-tightening force, and high precision requirements, so as to achieve safe valve opening and closing, and clear conversion relationship of spool sealing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] First of all, it should be noted that the specific implementation of the present invention is not limited to the following examples, and those skilled in the art should understand the present invention from the spirit embodied in the following examples, and each technical term can be based on the spirit of the present invention For the broadest understanding, for example, the valve stem is the part used to control the movement of the valve core.

[0071] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that the same or similar components in the drawings are indicated by the same reference numerals; and for the sake of clarity, the related schematic diagrams omit relevant components. Herein, up, down, left, and right directions refer to directions above, below, left, and right viewed from the drawing, unless otherwise specified.

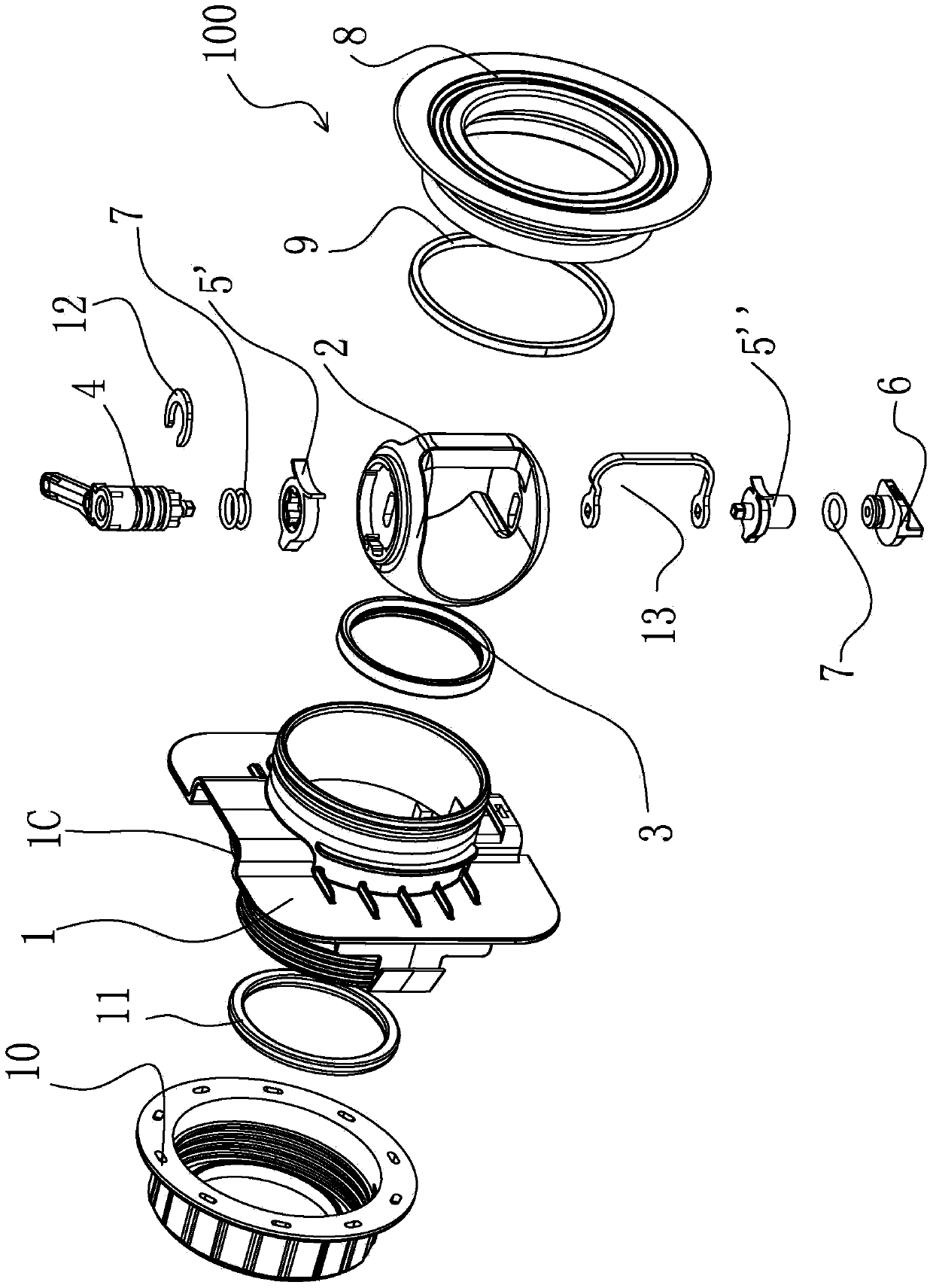

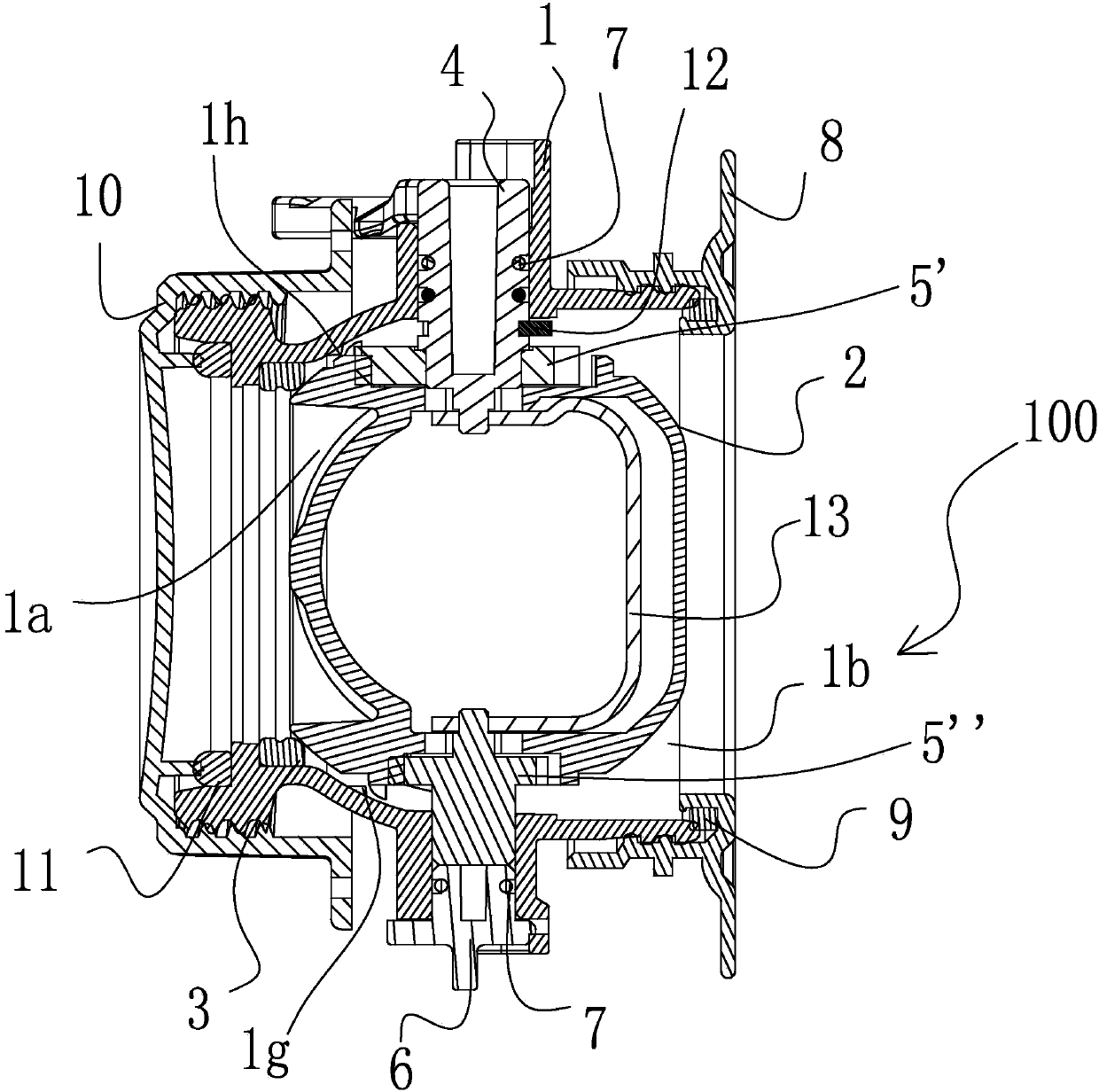

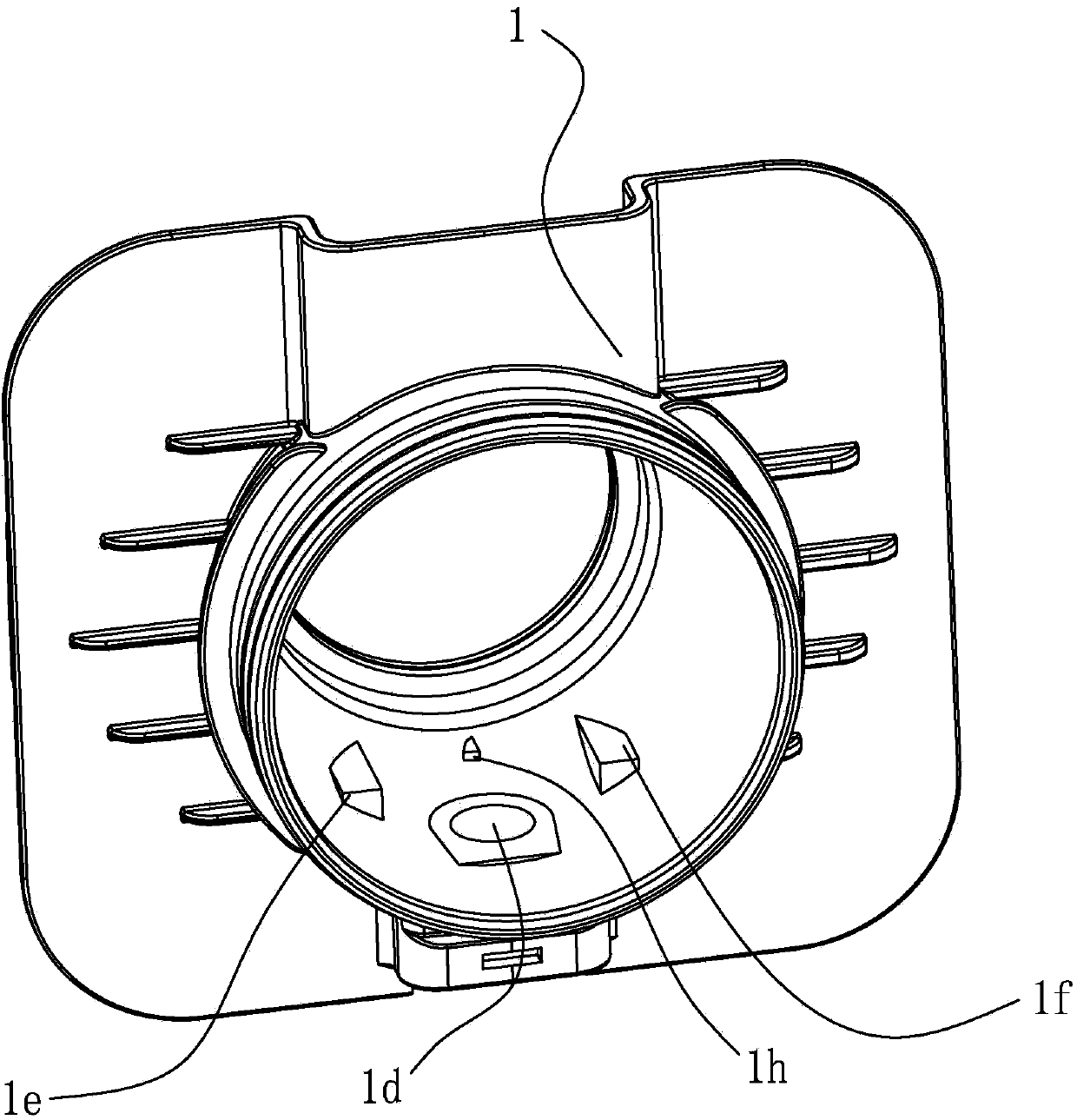

[0072] figure 1 An exploded perspective vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com