Energy-saving type hot wall heated brick bed and construction method thereof

An energy-saving, fire wall technology, applied in the field of indoor heating, can solve the problems of reduced contact area between flue gas and kang board, large size, and large exhaust loss, etc., to improve comprehensive utilization efficiency, high energy utilization rate, and fuel utilization rate high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

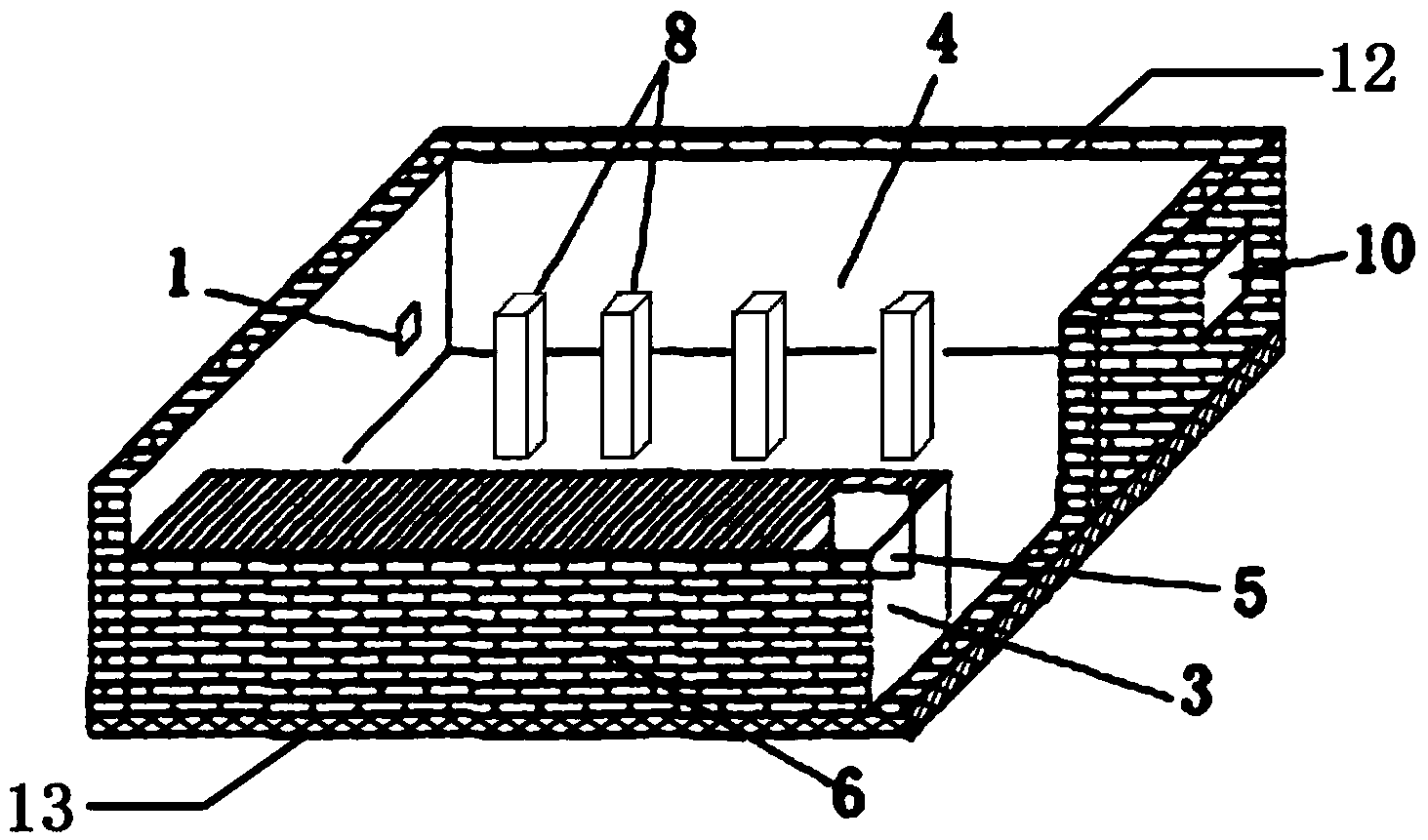

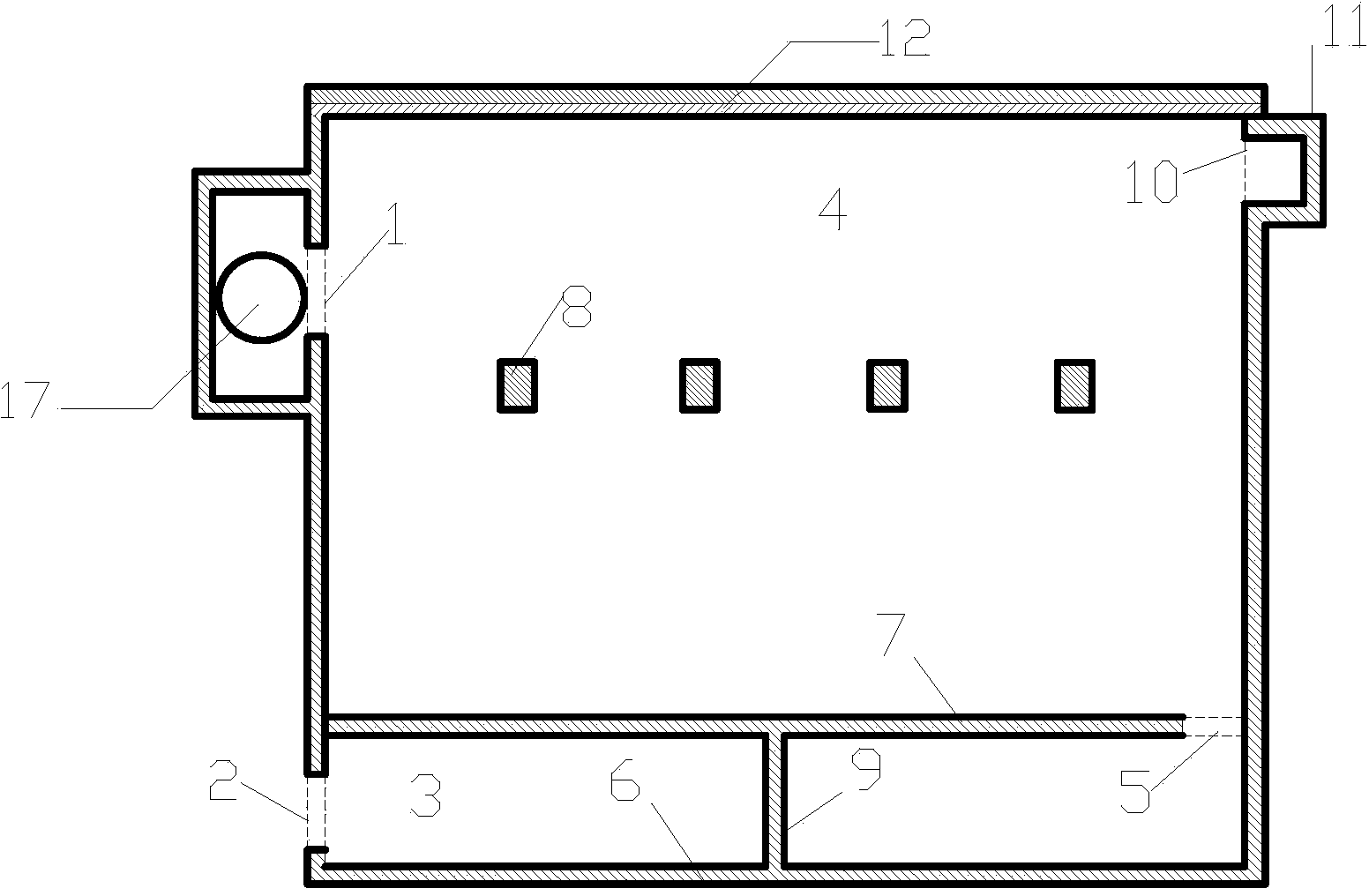

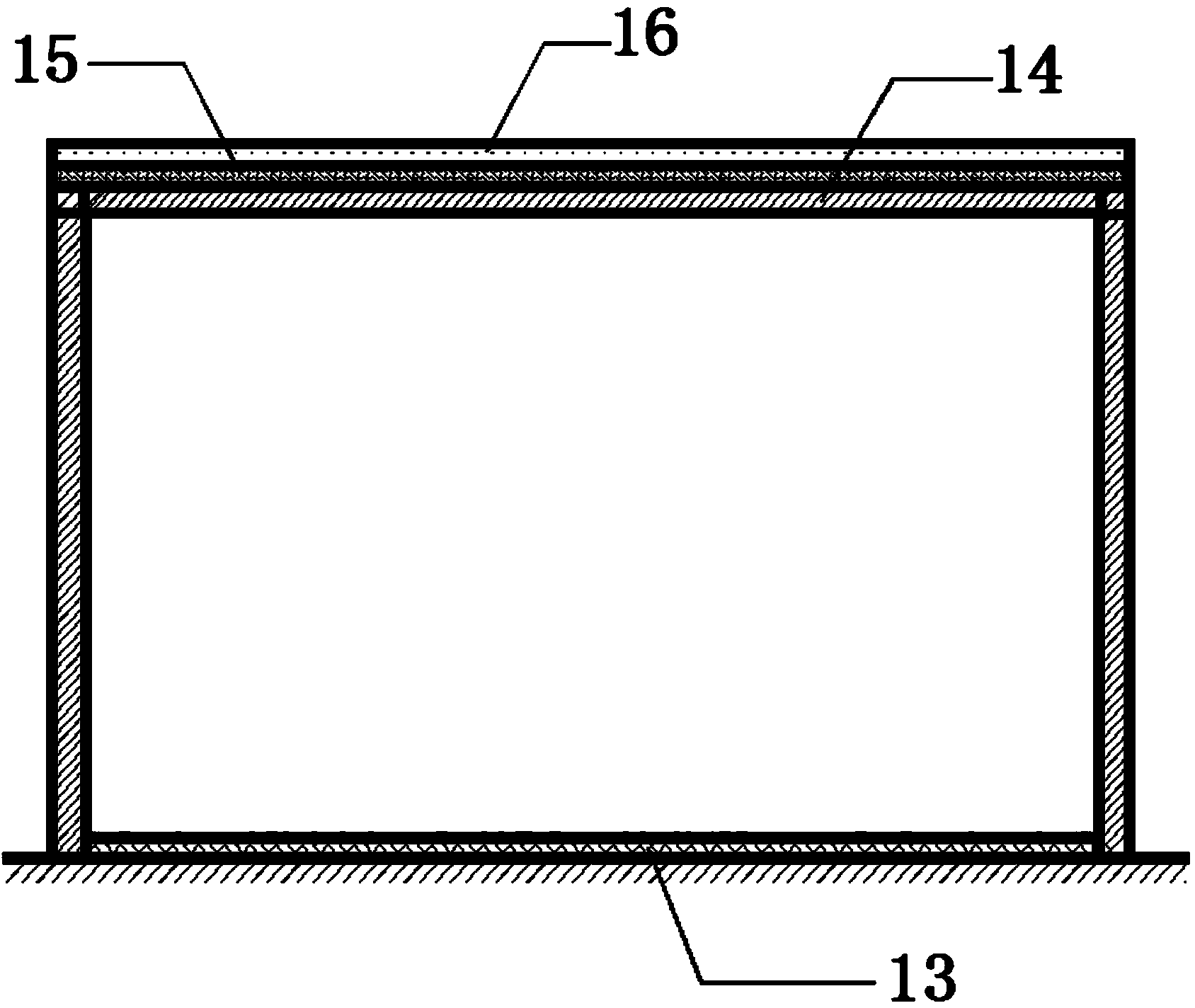

[0018] The present invention consists of a thermal insulation layer 13 at the bottom of the kang, a cooking stove 17, a flue gas inlet 1, a firewood (coal) opening 2 on a kang fire wall, a flue 3 on a kang fire wall, a hole 4 on a kang fire wall, a smoke outlet 5 on a kang fire wall, and a kang wall 6. Smoke-distributing wall 7, Kang panel pillar 8, ash retaining stack 9, smoke outlet 10, chimney 11, thermal insulation layer of Kang outer wall 12, Kang panel 14, Kang panel sealing layer 15, Kang panel decoration layer 16 and several composed of parts. The kang body is a hollow body, the kang body is provided with a kang panel pillar 8, the bottom of the kang body is provided with a thermal insulation layer 13, and the contact surface between the kang body and the outer wall is provided with an outer wall thermal insulation layer 12, and the kang body is connected to the outer wall. The flue of the Kang fire wall is arranged on the opposite side, and the middle part of the flue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com