Plant transpiration measuring device and method thereof

A technique for measuring plant transpiration and quantity, which is applied in the field of plant monitoring equipment, can solve problems such as complex principles, complicated conversion process, and inconvenient operation, and achieve the effect of accurate transpiration measurement and accurate data measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] For the preparation of gas exchange membranes, the following experimental steps were carried out,

[0032] A1. Take 110g of calcium chloride with a particle size of 50-100nm and stir it at a high speed in a 3000r / mim high-speed mixer until the temperature is about 90-100°C, then cool it down to 50°C naturally, and add 40g of non-ionic polyacrylamide. Continue to stir at 3000r / min at high speed for 150min, after activation and uniform treatment, seal and cool naturally to below 40°C, and set aside;

[0033] A2. Take 125g of low-density polyethylene, 350g of linear low-density polyethylene, 11g of thermoplastic elastomer, and 15g of high-temperature antioxidant. Feed the material to the main feeding port of the high-torque twin-screw machine, add it to the high-torque twin-screw machine, carry out mixing and plasticization, melt, extrude, cast and quench to form the primary product of gas exchange membrane;

[0034] A3. Immerse the primary product of the gas exchange mem...

Embodiment 2

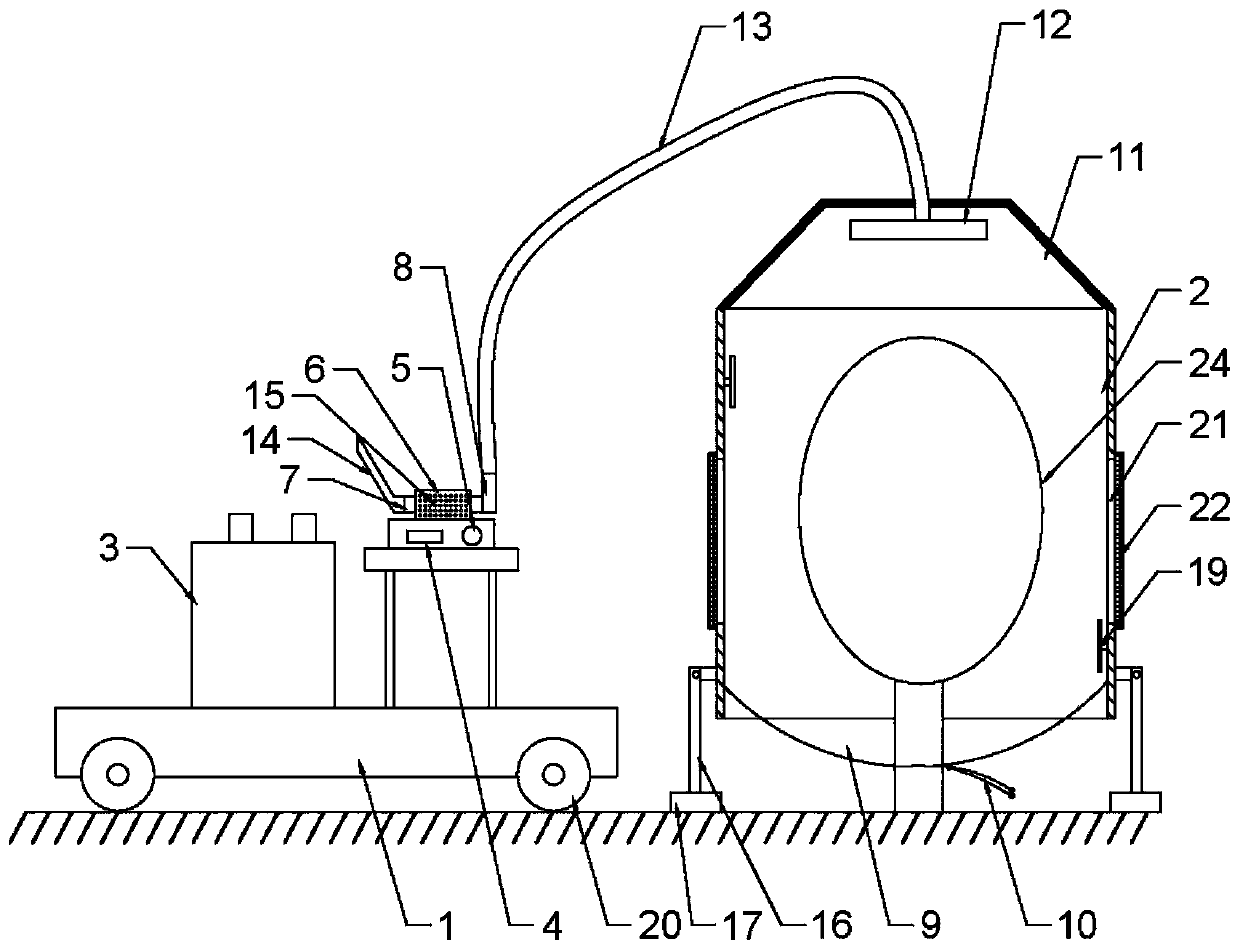

[0036] Embodiment 2: in combination with figure 1

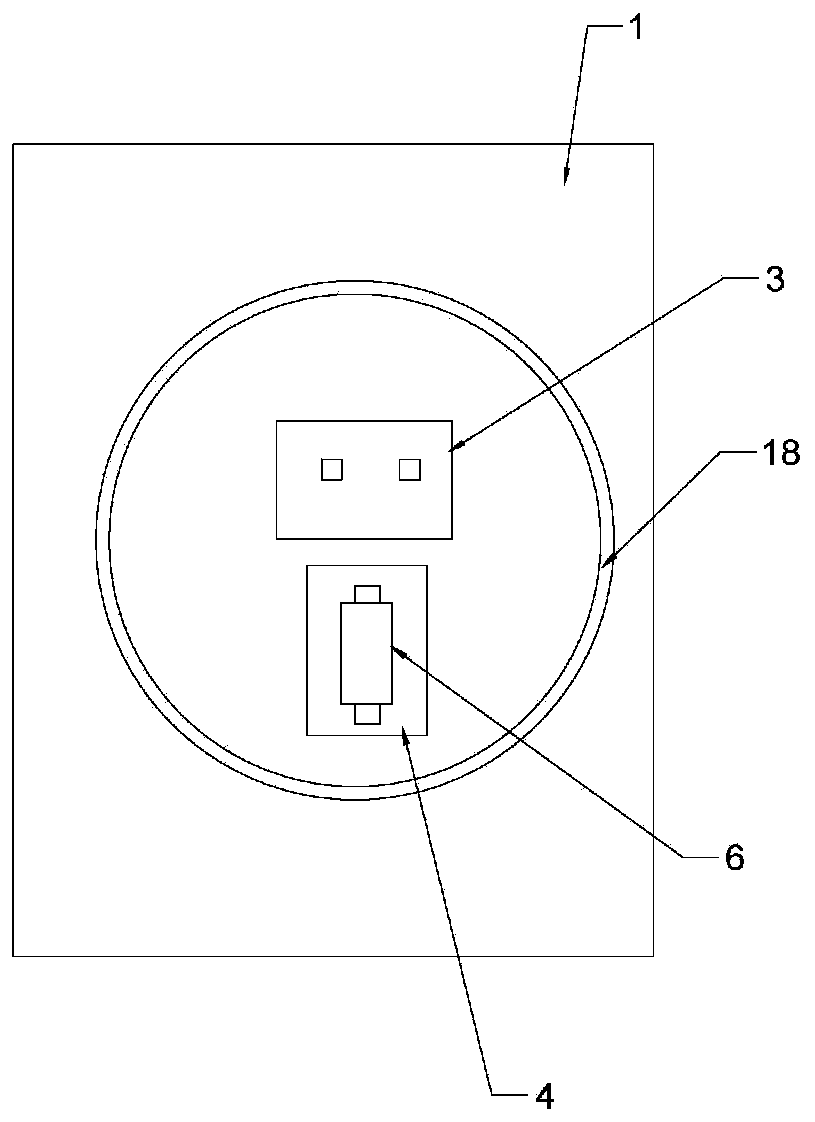

[0037]A device for measuring plant transpiration, comprising a machine base 1 and a transparent observation room 2, the observation room 2 is movably arranged on the machine base 1, and the machine base 1 is provided with a power supply 3 and an electronic weighing instrument 4, and the electronic weighing instrument 4 Electrically connected to the power supply 3, the electronic weighing instrument 4 is provided with a timer 5 and a filter box 6, the filter box 6 is provided with a first joint 7 and a second joint 8, and the lower side of the observation room 2 is provided with an opening surface, the opening surface A sealing cover 9 is fixedly connected to the inner wall of the sealing cover 9, and the end of the sealing cover 9 away from the opening surface is provided with a shrinking rubber band 10, and the upper side of the observation room 2 is provided with a conical cover 11, and the conical cover 11 is connected wit...

Embodiment 3

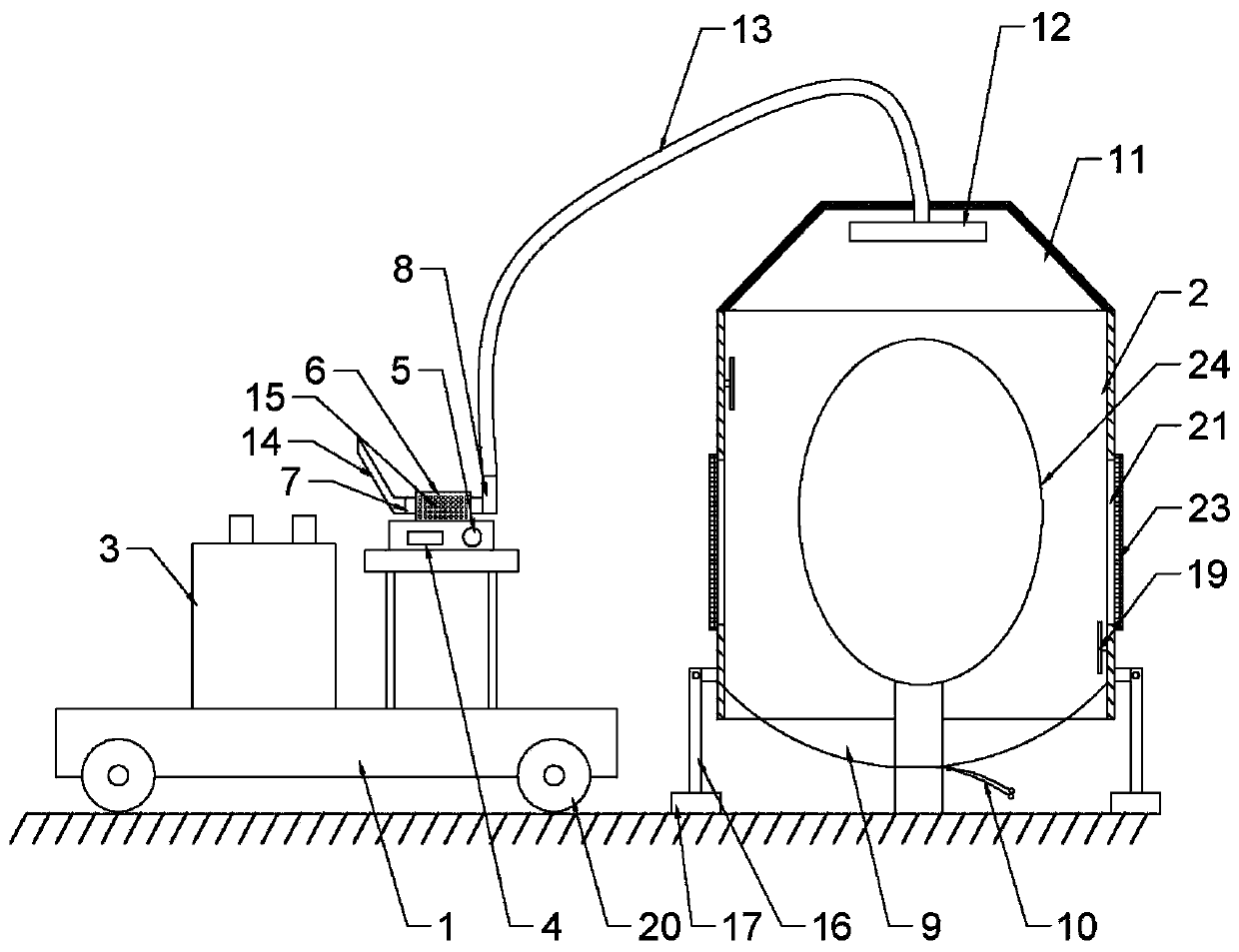

[0038] Embodiment 3: in combination with figure 2

[0039] A device for measuring plant transpiration, comprising a machine base 1 and a transparent observation room 2, the observation room 2 is movably arranged on the machine base 1, and the machine base 1 is provided with a power supply 3 and an electronic weighing instrument 4, and the electronic weighing instrument 4 Electrically connected to the power supply 3, the electronic weighing instrument 4 is provided with a timer 5 and a filter box 6, the filter box 6 is provided with a first joint 7 and a second joint 8, and the lower side of the observation room 2 is provided with an opening surface, the opening surface A sealing cover 9 is fixedly connected to the inner wall of the sealing cover 9, and the end of the sealing cover 9 away from the opening surface is provided with a shrinking rubber band 10, and the upper side of the observation room 2 is provided with a conical cover 11, and the conical cover 11 is connected w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com