Multi-working-condition composite indirect air processing device and air conditioning method thereof

An air-handling device and multi-working-condition technology, which is applied in air-conditioning systems, heating methods, space heating and ventilation, etc., can solve problems such as easy plugging of fillers, frequent cleaning of filters, and inability to meet the needs of air-conditioning systems, and achieve a large use area , Solve the difficulty of air filtration, easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

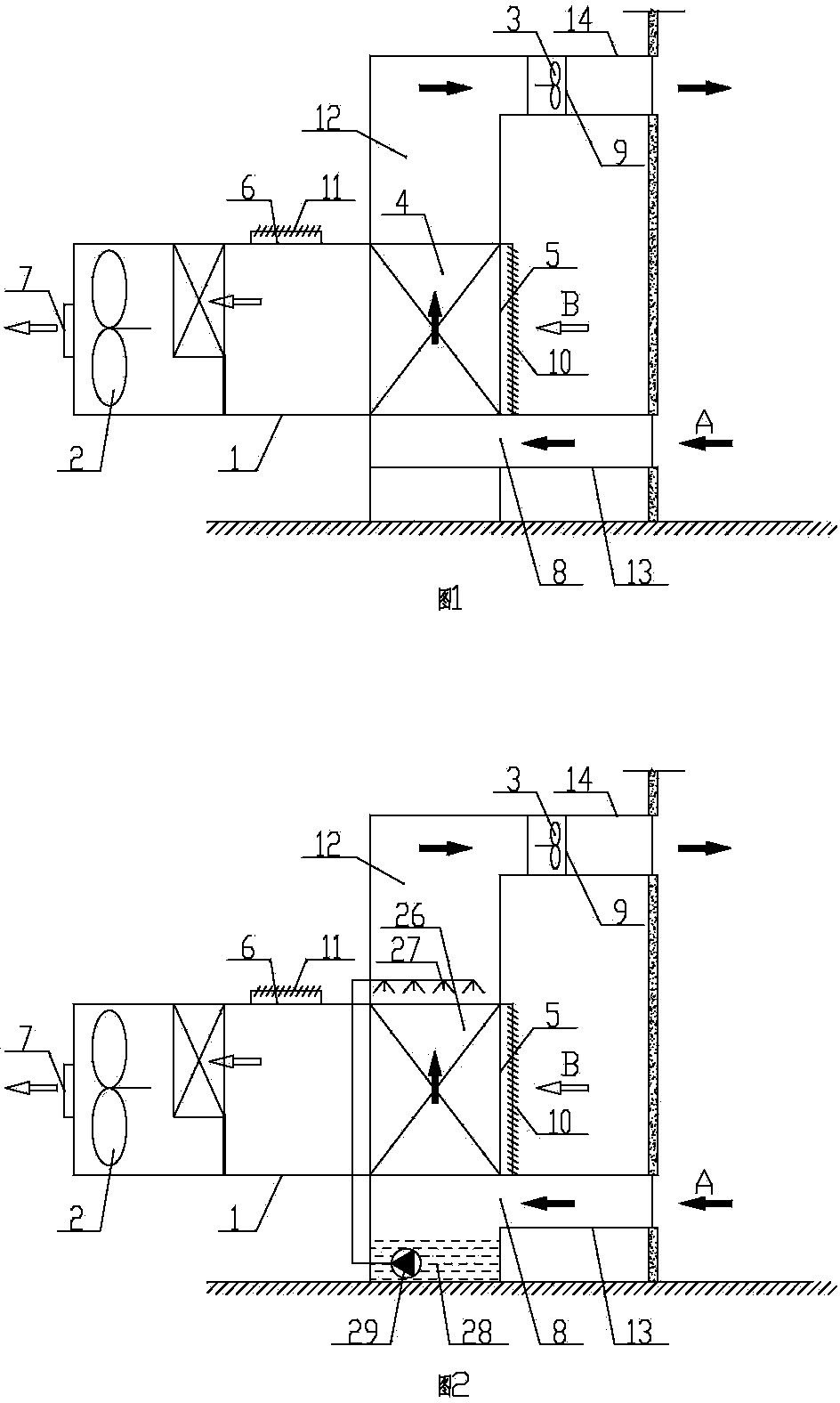

[0044] Embodiment 1: as attached figure 1 As shown, the multi-working-condition composite indirect air treatment device includes a housing 1, a blower 2, an exhaust fan 3, a partition heat exchange device 4 and a surface heat exchange device, and the housing 1 is provided with a first indoor air inlet port 5 , the second indoor air inlet port 6, the air supply port port 7, the process air inlet port 8 and the air exhaust port port 9, the first indoor air inlet port 5 and the indoor air second inlet port 6 are respectively provided with adjustable openings The first valve 10 and the second valve 11, the output air inlet of the partition heat exchange device 4 communicates with the room through the first inlet port 5 of the indoor air, the air inlet of the surface heat exchange device and the partition wall heat exchange device 4 The output air outlet is connected, the air inlet of the surface heat exchange device communicates with the room through the second indoor air inlet po...

Embodiment 2

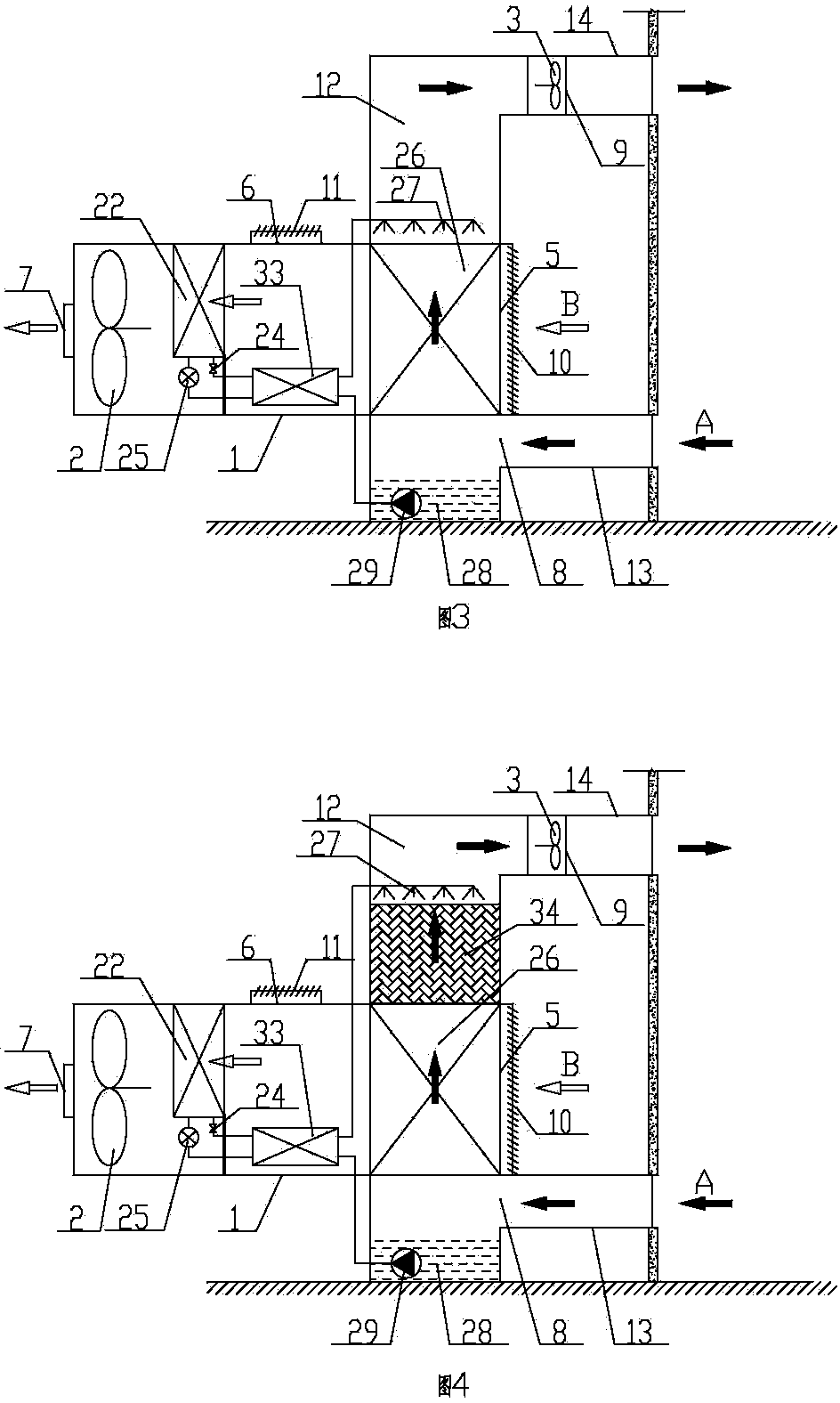

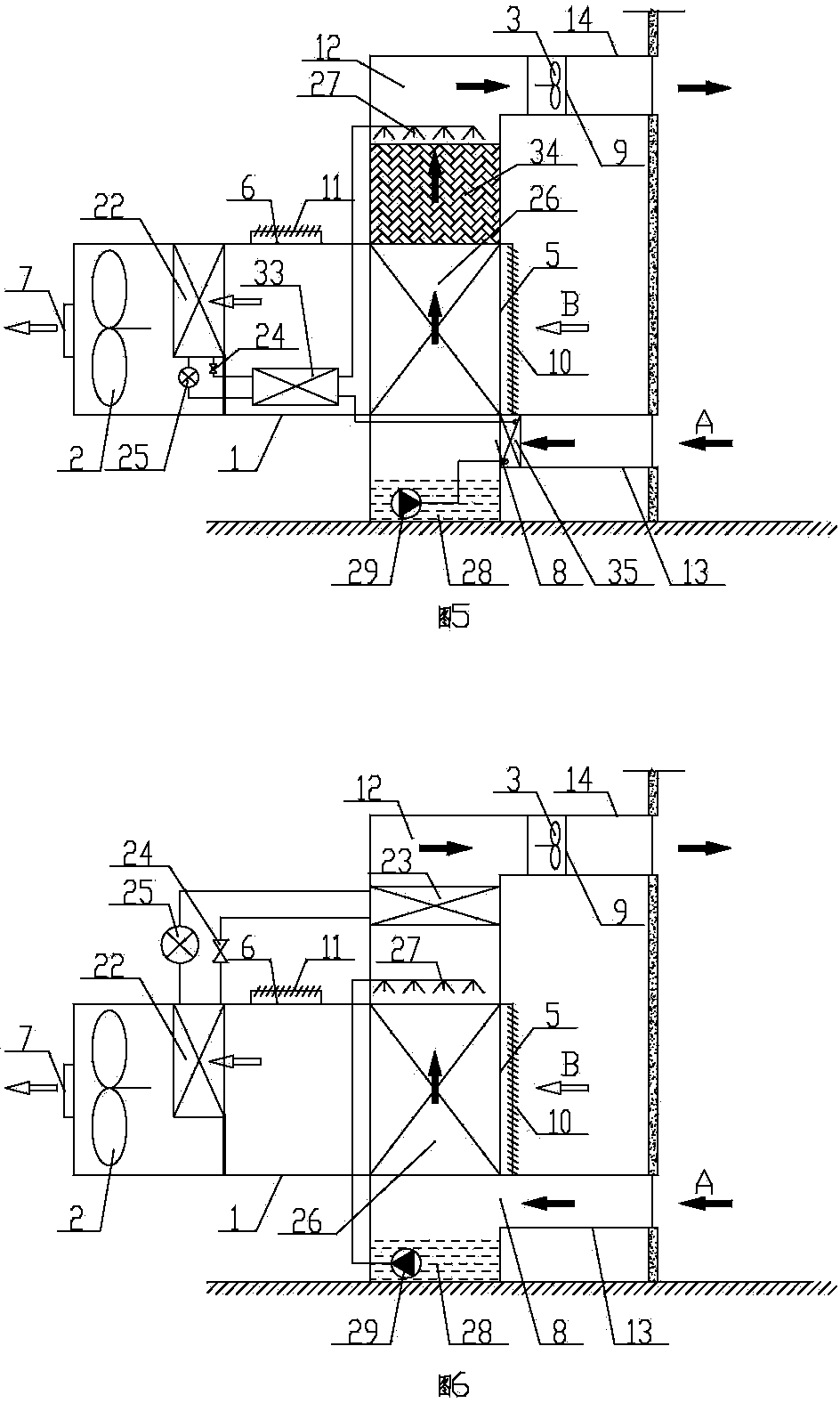

[0056] Embodiment 2: as attached figure 2 As shown, the difference between embodiment 2 and embodiment 1 is: the partition heat exchange device 4 of embodiment 2 is an indirect evaporative cooler; the indirect evaporative cooler includes an indirect evaporative heat exchange device 26, a spray device 27, a spray Spray circulating water tank 28 and spray circulating water pump 29, spray device 27 is provided above indirect evaporative heat exchange device 26, spray circulating water tank 28 is provided below indirect evaporative heat exchange device 26, and the water outlet of spray circulating water tank 28 The water inlet of the spray device 27 is communicated with the water inlet of the spray device 27 through the spray circulation pipeline with the spray circulation water pump 29 . The indoor return air enters the output air inlet of the indirect evaporative cooler through the first indoor air inlet port 5 as the output air B, and the outdoor fresh air enters the process a...

Embodiment 3

[0057] Embodiment 3: as attached image 3 As shown, the difference between embodiment 3 and embodiment 2 is that the surface heat exchange device of embodiment 3 is an evaporator 22, and a water-cooled condenser 33 is provided in the housing 1, and the water-cooled condenser 33 There is a water-cooling channel, the cooling water inlet of the water-cooling channel communicates with the spraying circulating water tank 28 through a pipeline with a spraying circulating water pump 29, and the cooling water outlet of the water-cooling channel passes through the water inlet of the spraying device 27 The pipelines are connected, and the refrigerant outlet of the water-cooled condenser 33 is communicated with the refrigerant inlet of the evaporator 22 through a refrigerant pipeline with a throttle valve 24, and the refrigerant inlet of the water-cooled condenser 33 is connected through a refrigerant pipeline with a compressor The refrigerant pipeline of 25 communicates with the refrige...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com