Production method of low-purine beer

A production method and a purine technology are applied in the production field of low-purine beer, can solve problems such as lowering production costs, unsuitable beer for gout patients, and achieve the effects of improving utilization rate, low purine content and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

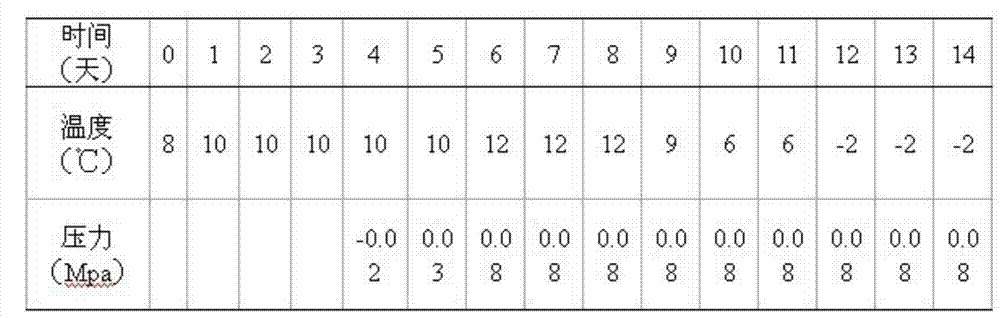

Image

Examples

Embodiment 1

[0033] The process adopts the enzymatic double mash leaching secondary saccharification production process: malt powder 250kg, barley flour 100kg, rice flour 650kg; mash water ratio 1:3, gelatinization pot water ratio 1:5.

[0034] (1) Saccharification

[0035] Add 1050kg of warm water at 45°C to the mash pot, adjust the pH to 5.4~5.6 with phosphoric acid, add 250kg of malt powder and 100kg of barley flour, of which malt powder is 87.5kg of husk, 112.5kg of coarse powder, and 50kg of fine powder, and then add CaCl 2 0.25Kg, the compound enzyme is 0.25kg of β-glucanase, 0.25kg of β-amylase, 0.5kg of protease, 0.25kg of hemicellulase, 0.5kg of papain, and keep warm for 60min for nucleic acid sedimentation treatment, and mash after 60min ;

[0036] (2) Gelatinization

[0037] Add 3250kg of warm water at 53°C to the gelatinization pot, add 0.065Kg of CaCl 2 , adjust the pH to 5.8~6.0 with phosphoric acid, add 650kg of rice flour, add 195ml of high temperature resistant a-amylas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com