Combined type direct-heating resistance furnace

A resistance furnace and combined technology, applied in furnaces, electric furnace heating, furnace components and other directions, can solve problems such as excessive leakage current, increase leakage current of resistance heaters, and resistance heaters not working, saving equipment installation space, The effect of reducing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

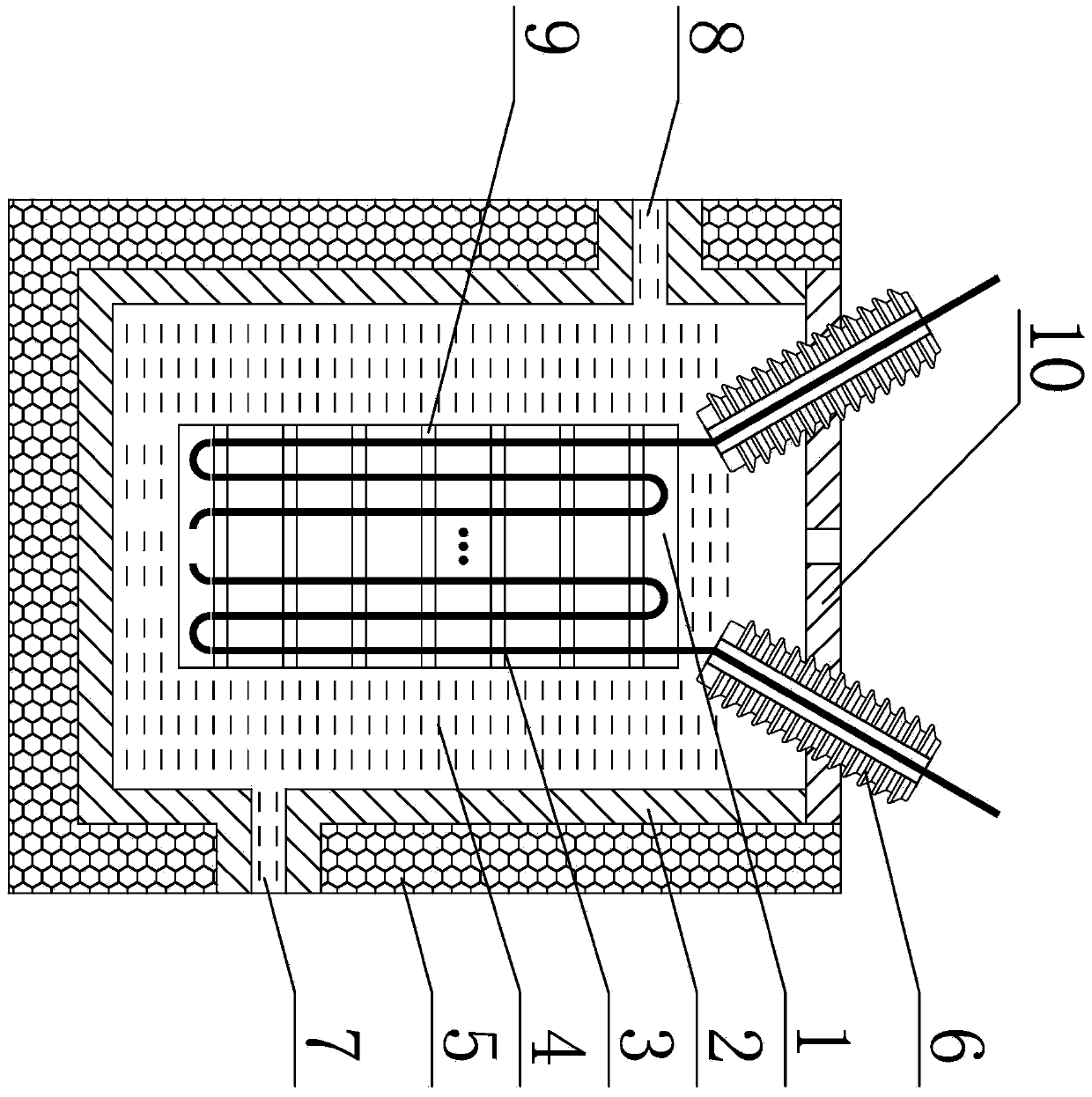

[0020] The structure of the resistance heating unit of the combined direct heating resistance furnace of the present invention is as follows: figure 1 As shown, the metal wire 3 is fixed by the structural member 9 to make the assembled resistance heater assembly 1 firm and stable, and the two ends of the metal wire 3 are connected with insulating sleeves 6 to integrate with the resistance heater assembly 1, and then put into the unit case Inside the body 2, an insulation layer 5 is installed on the outer surface of the unit casing 2.

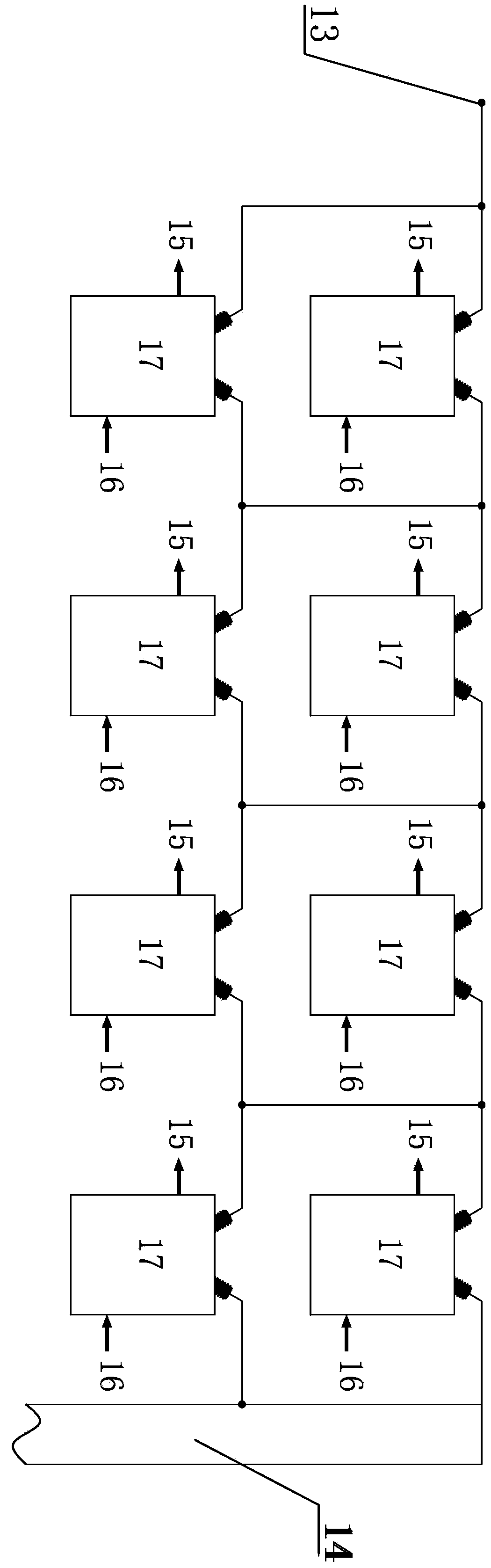

[0021] The structure of the combined direct heating resistance furnace heating unit group of the present invention is as follows: figure 2 As shown, the heating unit group is composed of 8 resistance heating units connected in two parallels and four in series, one end is connected to the power lead-out line 13, and the other end is connected to the neutral point lead-out line 14.

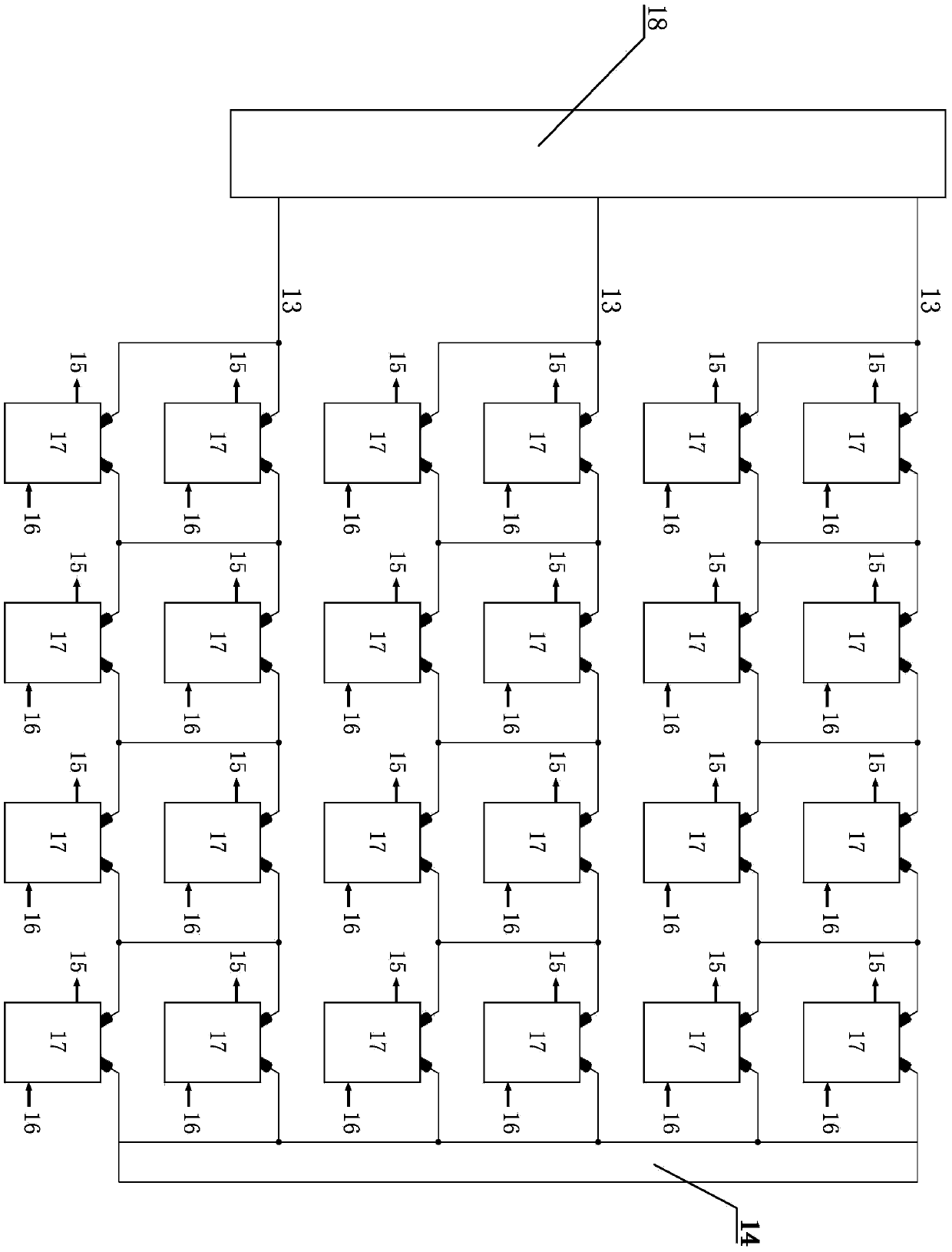

[0022] Three groups of heating units with the same structure i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com