Detection instrument for bonding strength of ferromagnetic coating of remanufactured parts

A technology of bonding strength and parts, applied in the field of ferromagnetic coating bonding strength detectors for remanufactured parts, can solve problems such as ferromagnetic coating bonding strength measurement, save energy consumption, improve work efficiency, and detect accurate and stable Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further understand the invention and creation content, characteristics and effects of this patent, the following examples are exemplified, and detailed descriptions are as follows in conjunction with the accompanying drawings:

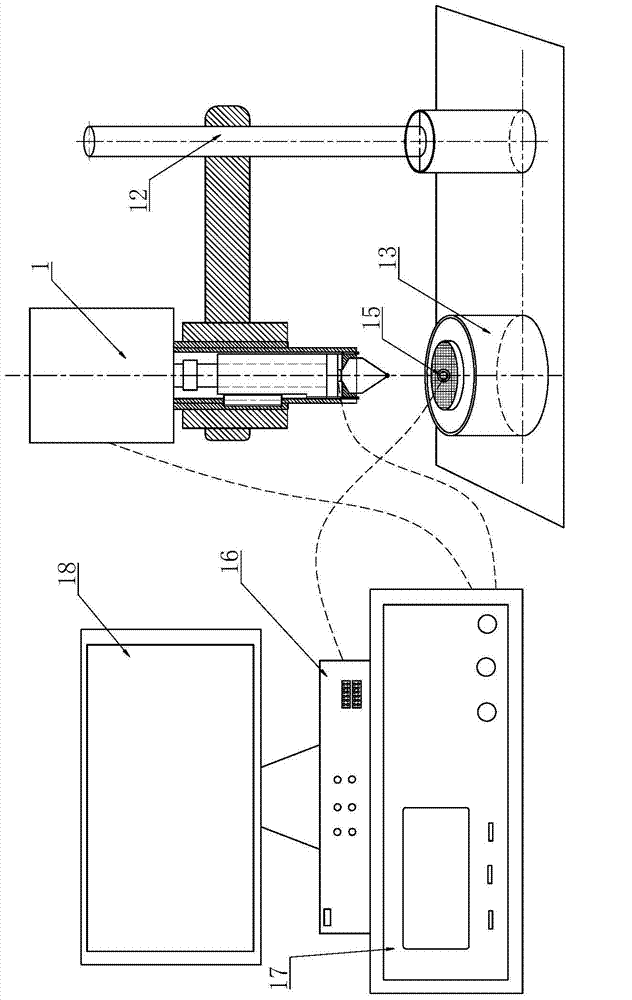

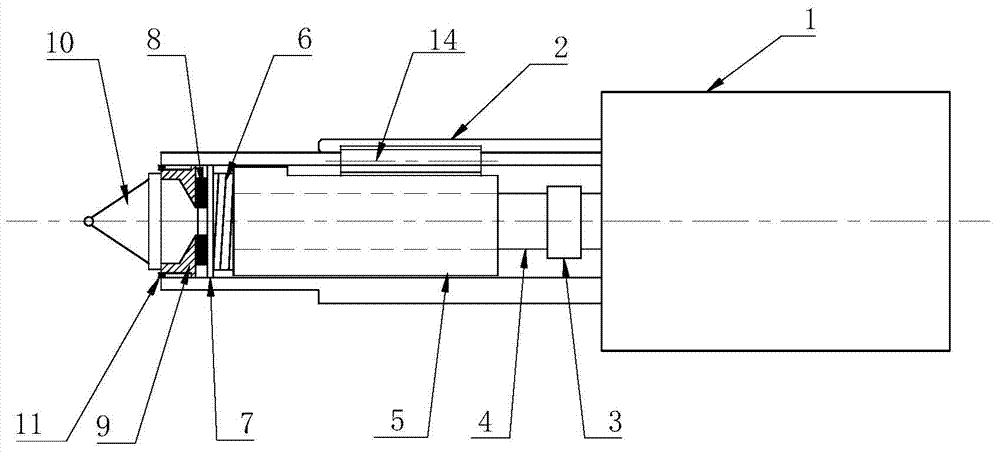

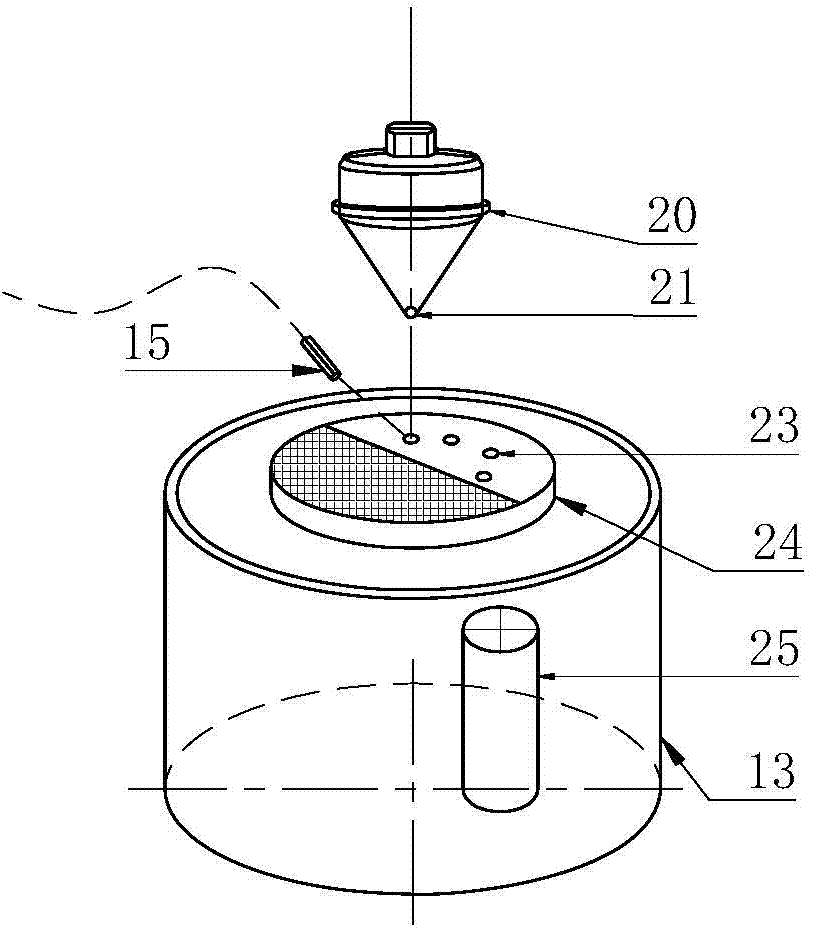

[0026] Such as figure 1 and 2 and 3,

[0027] A ferromagnetic coating bonding strength tester for remanufactured parts, including a load drive mechanism, a control device 17, a detection device and a support mechanism,

[0028] The load drive mechanism includes a servo motor 1 as a power device, a transmission mechanism and a pressure head 21 connected with the transmission mechanism. The servo motor 1 is installed on one end face of the drive mechanism shell 2. The transmission mechanism includes a screw rod 4 and a nut movable sleeve 5, a guide Block 14, one end of screw rod 4 is connected with servomotor 1 by shaft coupling 3, and nut movable sleeve 5 is threaded on the screw rod 4, and guide block 14 cooperates with nut movable...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com