Can bottom double-sided code spraying anti-counterfeiting mode

A double-sided, can-bottom technology, which is applied to record carriers used in machines, instruments, computer parts, etc., can solve the problem of waste of packaging cans, achieve the effect of simple appearance, not easy to forge and counterfeit, and prevent cross-selling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

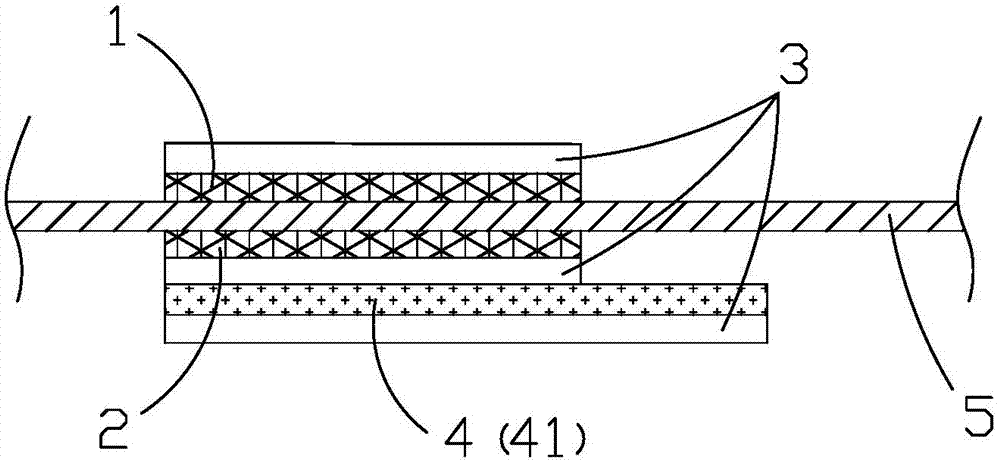

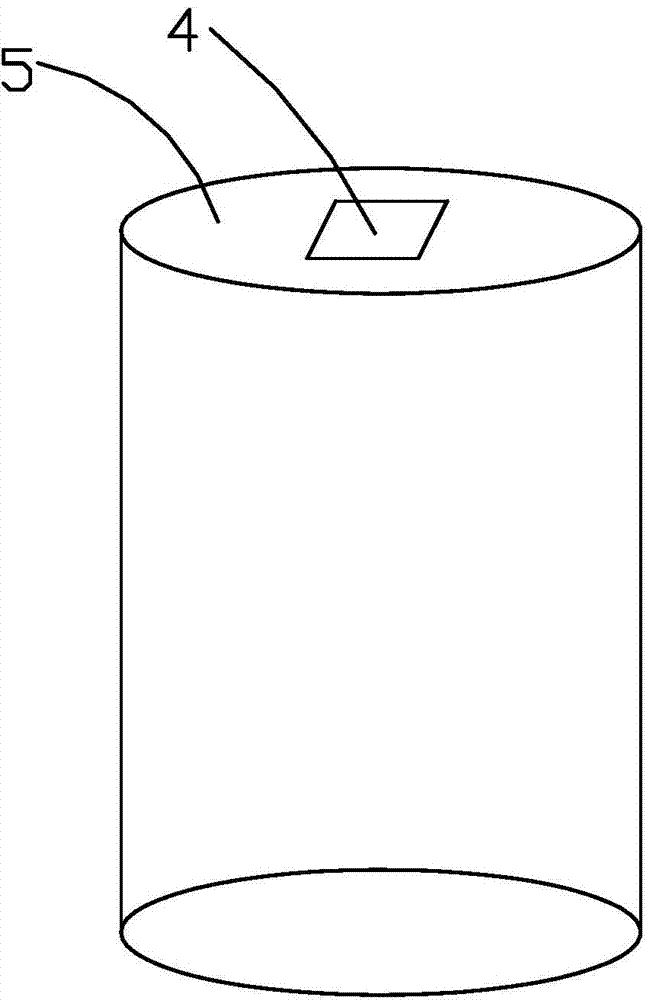

[0021] This embodiment discloses an anti-counterfeiting method of spraying codes on both sides of the tank bottom. The product packaging is used as the carrier, and the inner and outer surfaces of the product packaging are provided with corresponding information layers. The packaging of this embodiment is a traditional milk powder can, and the material of the tank is tinplate ,Such as figure 1 with figure 2 As shown, before the product is poured, the 10-digit binary code is sprayed on the inside and outside of the tank bottom 5 in batches, such as "0123456789", the inner code 1 and the outer code 2 are consistent, and a protective layer 3 is covered to avoid the coating material Contamination of food and wear and tear of the outer code, the binary code is coded. After the milk powder is poured and packaged, read the 10-digit binary code outside the bottom of the tank through the code reading device and input it into the central processing system. At the same time, the centra...

Embodiment 2

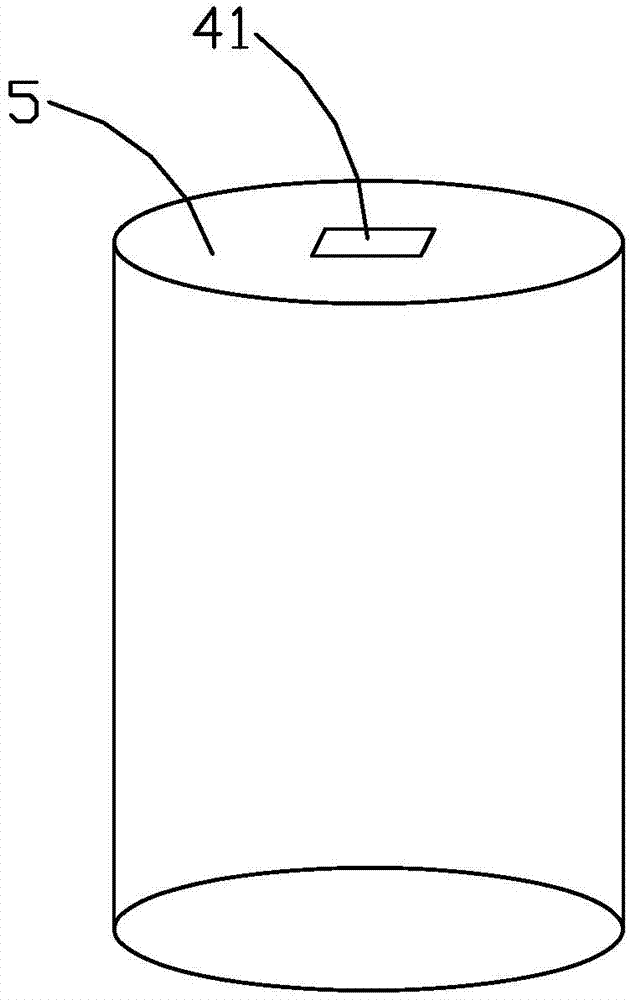

[0023] The difference between embodiment 2 and embodiment 1 lies in the adopted clear coding method, which adopts the form of bar code. Such as figure 1 with 3 After the milk powder is poured and packaged, read the 10-digit binary code outside the bottom of the tank through the code reading device and input it into the central processing system. At the same time, the central processing system obtains other information about the batch of milk powder produced from the memory, such as Production date, production batch number, production place, source of material, etc., integrate the code corresponding to these information with the obtained binary code to form a 20-digit clear code 41, and convert it into a barcode form, and store the barcode 41 in the product information public query System, let the package pass through the coding system again, spray the corresponding barcode and the product's production date, production batch number, production place information, and cover it w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com