Internalization process of a valve-regulated lead-acid battery for electric vehicles

A lead-acid battery, electric vehicle technology, applied in lead-acid battery, lead-acid battery construction, secondary battery and other directions, can solve problems such as lead pollution, water waste, heavy metal cadmium content exceeding the standard, and achieve early capacity attenuation, Ensure consistency and solve the effect of short life in deep cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A process for internalizing a valve-regulated lead-acid battery for an electric vehicle, comprising the steps of:

[0022] (1) Manufacturing of lead powder: the prepared lead powder is stored for 72 hours, the oxidation degree of the positive electrode lead powder is 78-82%, and the apparent density is 1.3-1.4g / cm 3 ;The oxidation degree of lead powder is 75-80%, and the apparent density is 1.4-1.5g / cm 3 ;

[0023] (2) Grid manufacturing: including a positive grid and a negative grid, the grid is cast from a lead-calcium alloy, and the mass percentage of each component in the lead-calcium alloy of the positive grid is Ca 0.12%, Al 0.02%, Sn 1.6%, the Pb of balance; The mass percent of each component in the lead-calcium alloy of described negative electrode grid is Ca 0.12%, Al 0.02%, Sn 0.15%, the Pb of balance;

[0024] (3) Grid surface treatment: The treatment process includes two stages, among which, the treatment temperature of the first stage is 90°C, the humidit...

Embodiment 2

[0029] Compared with Example 1, the difference is that in step (2) the mass percent of each component in the lead-calcium alloy of the positive grid is Ca 0.12%, Al 0.02%, Sn 1.5%, and Pb in the balance; the negative electrode The mass percent of each component in the lead-calcium alloy of the grid is Ca 0.12%, Al 0.02%, Sn 0.1, and the balance Pb.

Embodiment 3

[0031] Compared with Example 1, the difference is that in step (2) the mass percent of each component in the lead-calcium alloy of the positive grid is Ca 0.12%, Al 0.02%, Sn 1.7%, and Pb in the balance; the negative electrode The mass percentage of each component in the lead-calcium alloy of the grid is Ca 0.12%, Al 0.02%, Sn 0.2, and the balance Pb.

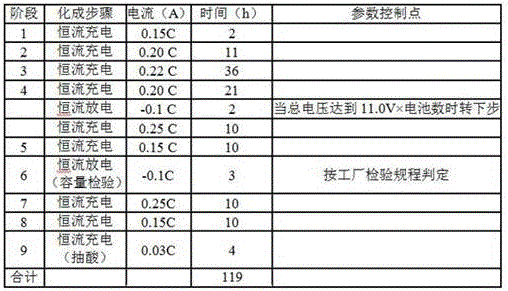

[0032] Table 1 Step (6) charging process

[0033]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com