Preparation method of activated carbon filter

A technology of activated carbon filter and production method, which is applied in the direction of gravity filter, chemical instrument and method, loose filter material filter, etc., can solve the problems of small liquid flow rate and inability to absorb heavy metals, etc., and achieve the increase of liquid flow rate, The effect of avoiding secondary pollution and reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

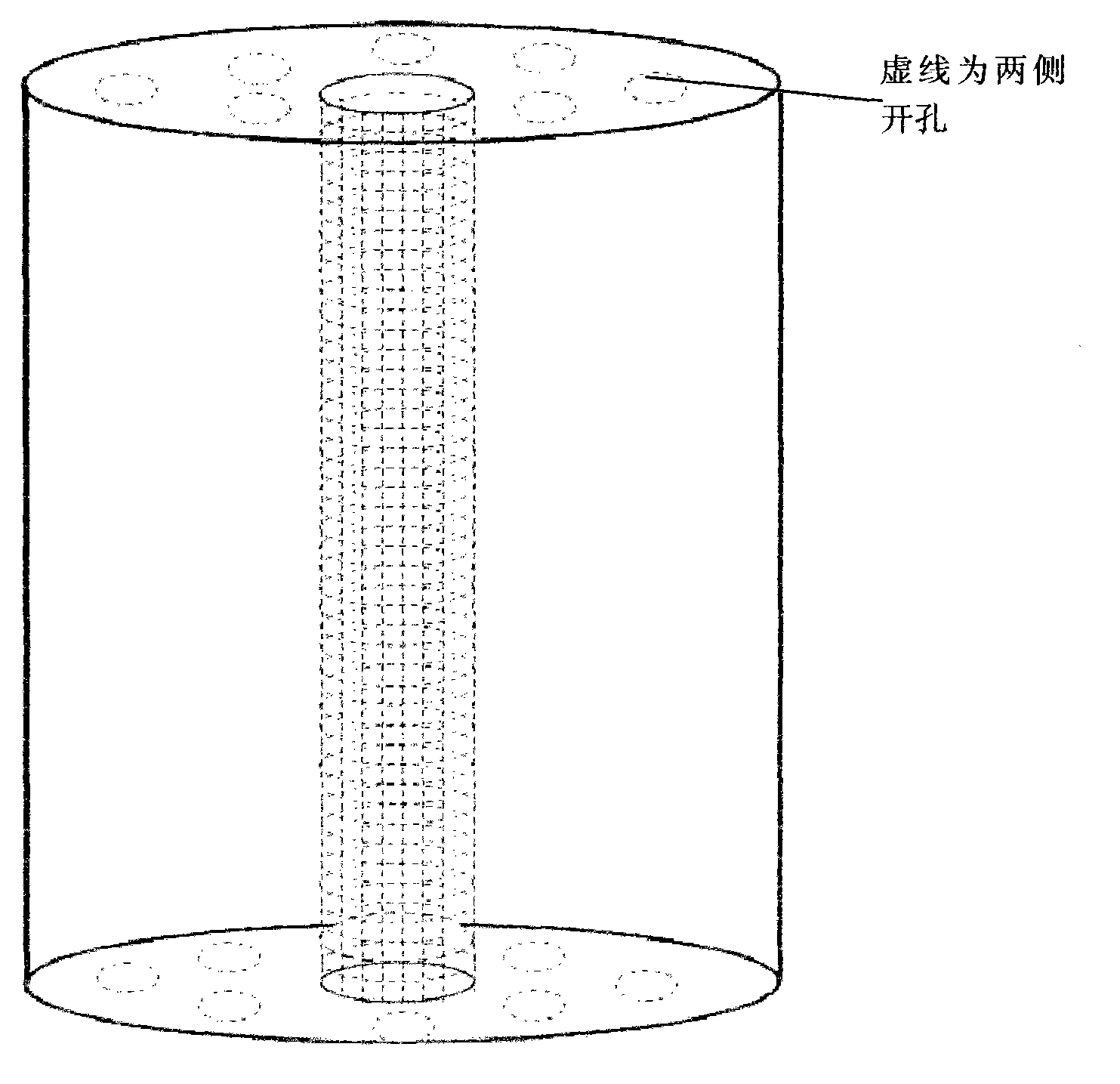

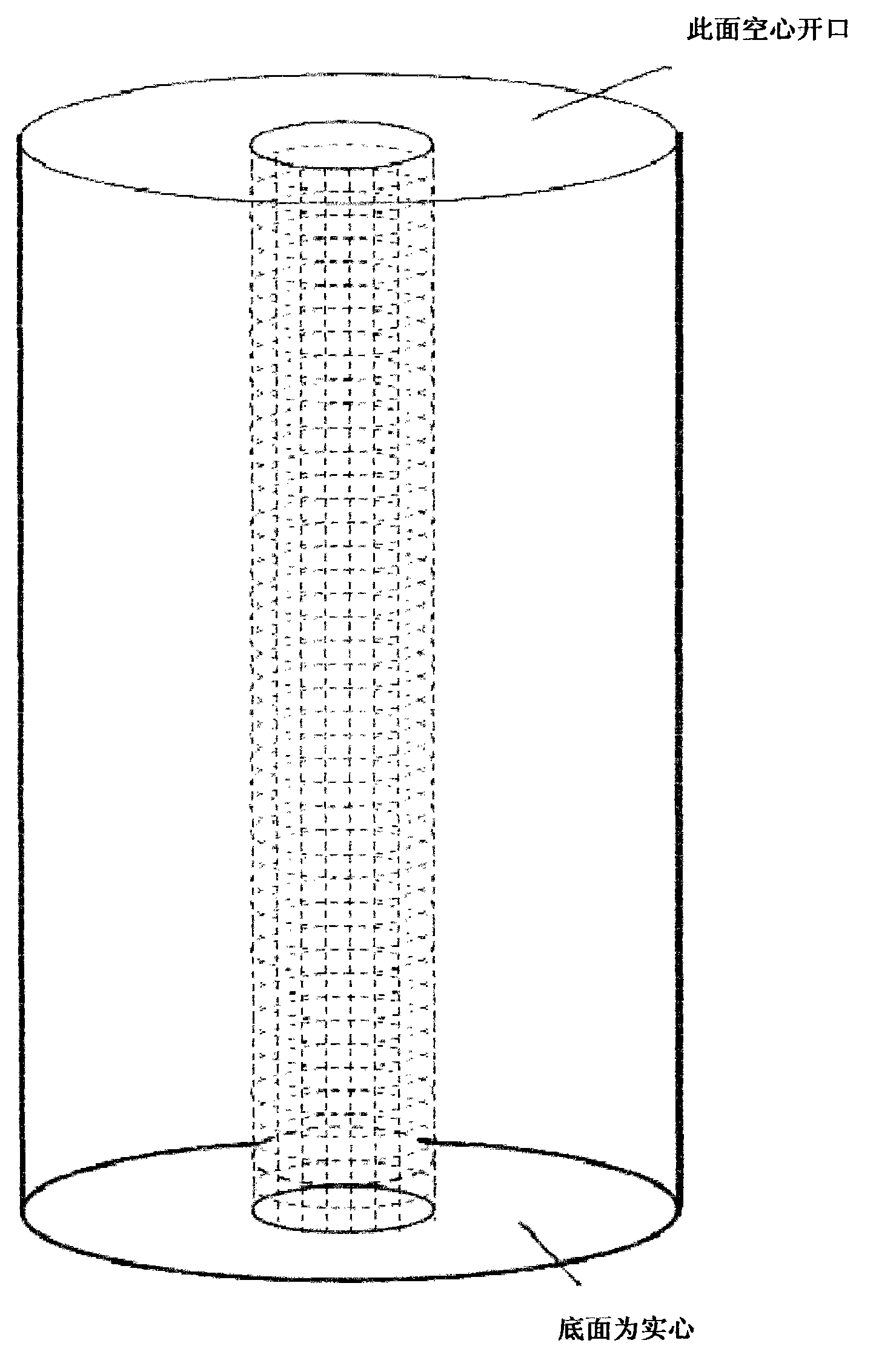

[0019] Such as Figure 1-2 As shown, the manufacturing method of the filter described in the embodiment of the present invention mainly includes the following steps:

[0020] (1) Prepare raw materials: First, put 100-325 mesh powdered activated carbon into the raw material pool, then put 100-250 mesh powdered activated zeolite into the raw material pool, and put an appropriate amount of adhesive into the raw material pool, according to the weight ratio of 1:10 Inject water into the raw material pool, then put synthetic fibers (1.5d×3mm and 2d×2mm) into the raw material pool, the automatic mixer stirs the raw material pool for 20 minutes, and wrap two layers of non-woven fabric on the porous plastic tube;

[0021] (2) Suction forming method: pump the raw materials in the raw material pool into the tank, install the porous plastic tube in the center of the injector, then dip the injector into the tank, open the injector, and the raw materials in the tank gather in the porous Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com