Rotary type ultrahigh pressure supercharger of synthetic diamond cubic press

A technology of six-sided top press and synthetic diamond, which is applied in the application of ultra-high pressure process and other directions, can solve the problem that the supercharger can not fully meet the needs of supercharging, and achieve the effect of improving the flow range and pressure range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

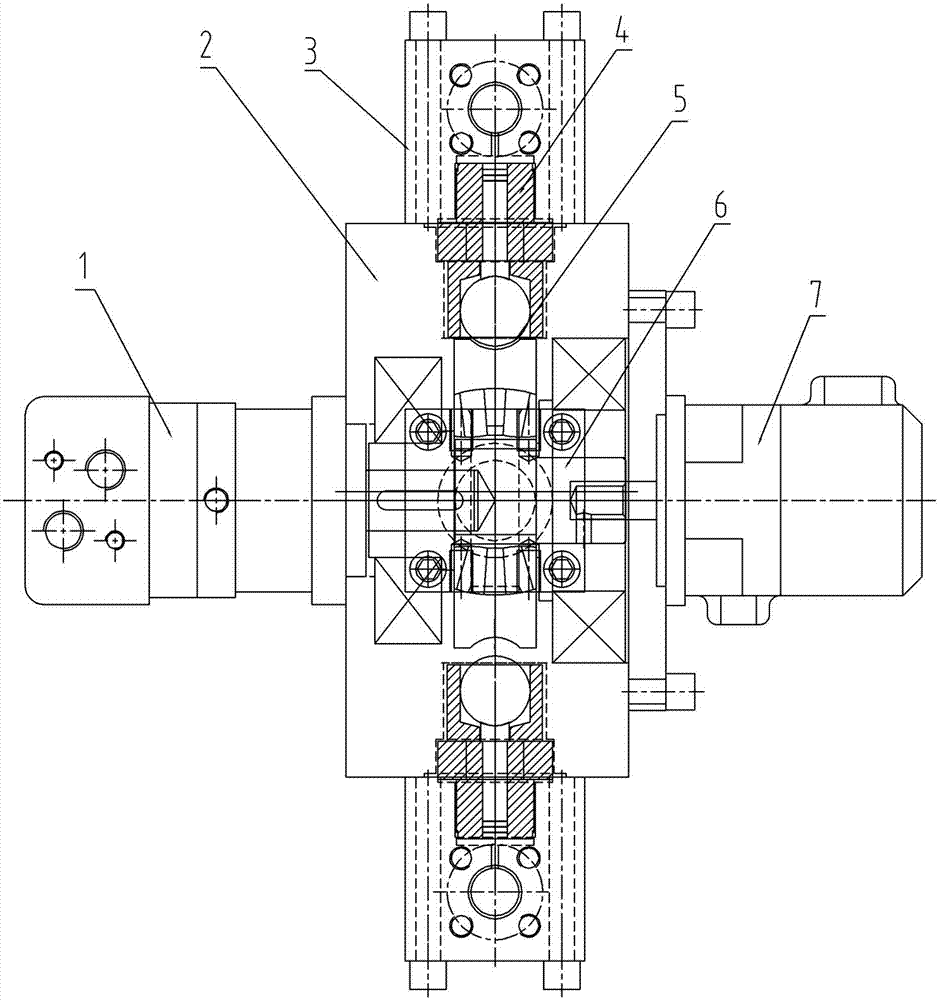

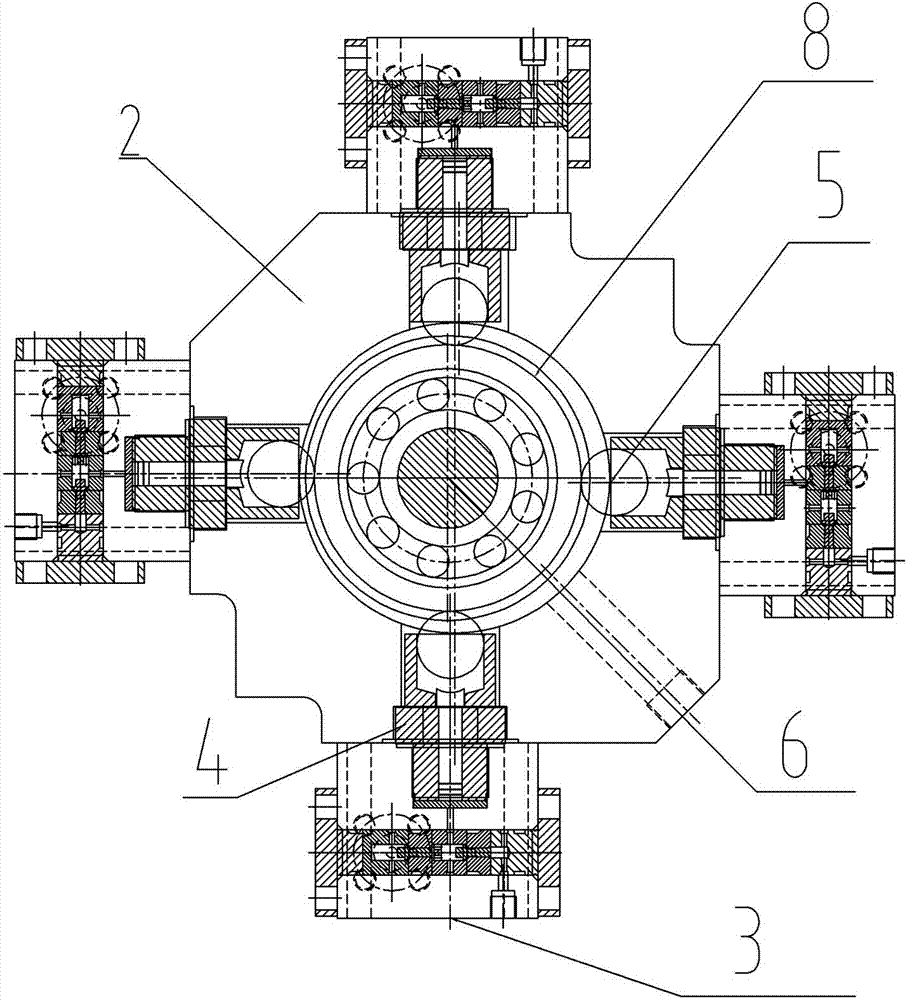

[0017] Such as figure 1 and figure 2 As shown in the figure, the rotary ultra-high pressure supercharger for a synthetic diamond six-sided top press includes a casing 2 and an eccentric shaft 6 passing through the casing. A power source 1 and an oil supply pump 7 are installed on the casing, and the periphery of the casing is uniform. Four oil distribution valve bodies 3 are distributed, and a plunger 4 is installed on the oil distribution valve body, and a transition ball 5 is arranged between the plunger 4 and the eccentric shaft. The power source is fixed on the housing through a flange. The power source is a hydraulic motor, and may also be an electric motor. A bearing 8 is sleeved on the eccentric shaft, and the transition ball is located between the bearing and the plunger. The transitional sphere is a steel ball. The eccentricity of the eccentric shaft is 4mm.

[0018] The rotary supercharger uses a hydraulic motor or an electric motor (preferably a hydraulic moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com