Low pressure casting die for multi-point isolated heat spot type large gearbox casing

A large-scale gear, low-pressure casting technology, applied in the field of low-pressure casting molds for large-scale gear boxes with multi-point isolated thermal joints, can solve problems such as shortened service life, thermal deformation, cavity structure changes, etc., to improve processing quality and prevent excessive temperature. High and guaranteed performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

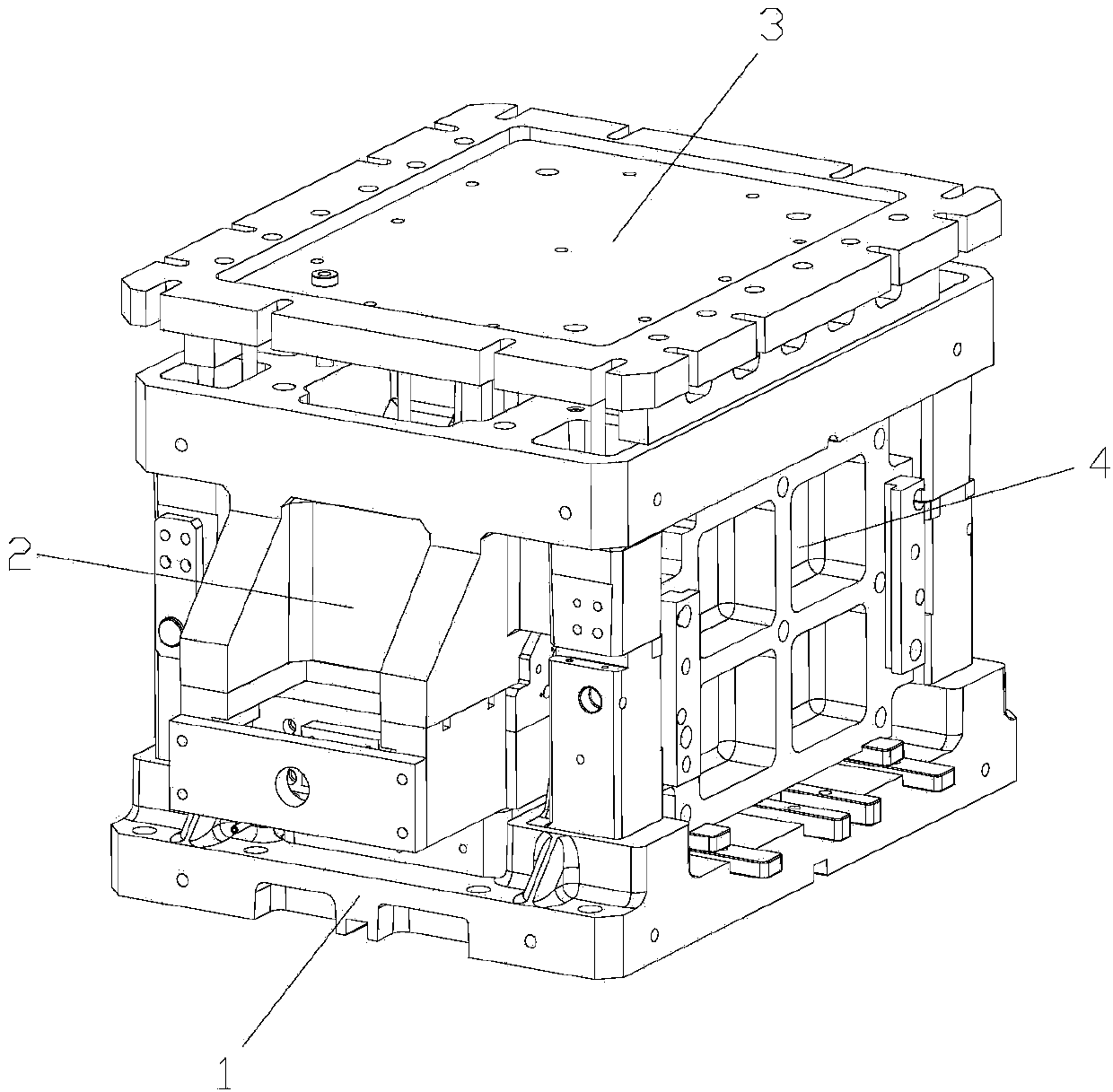

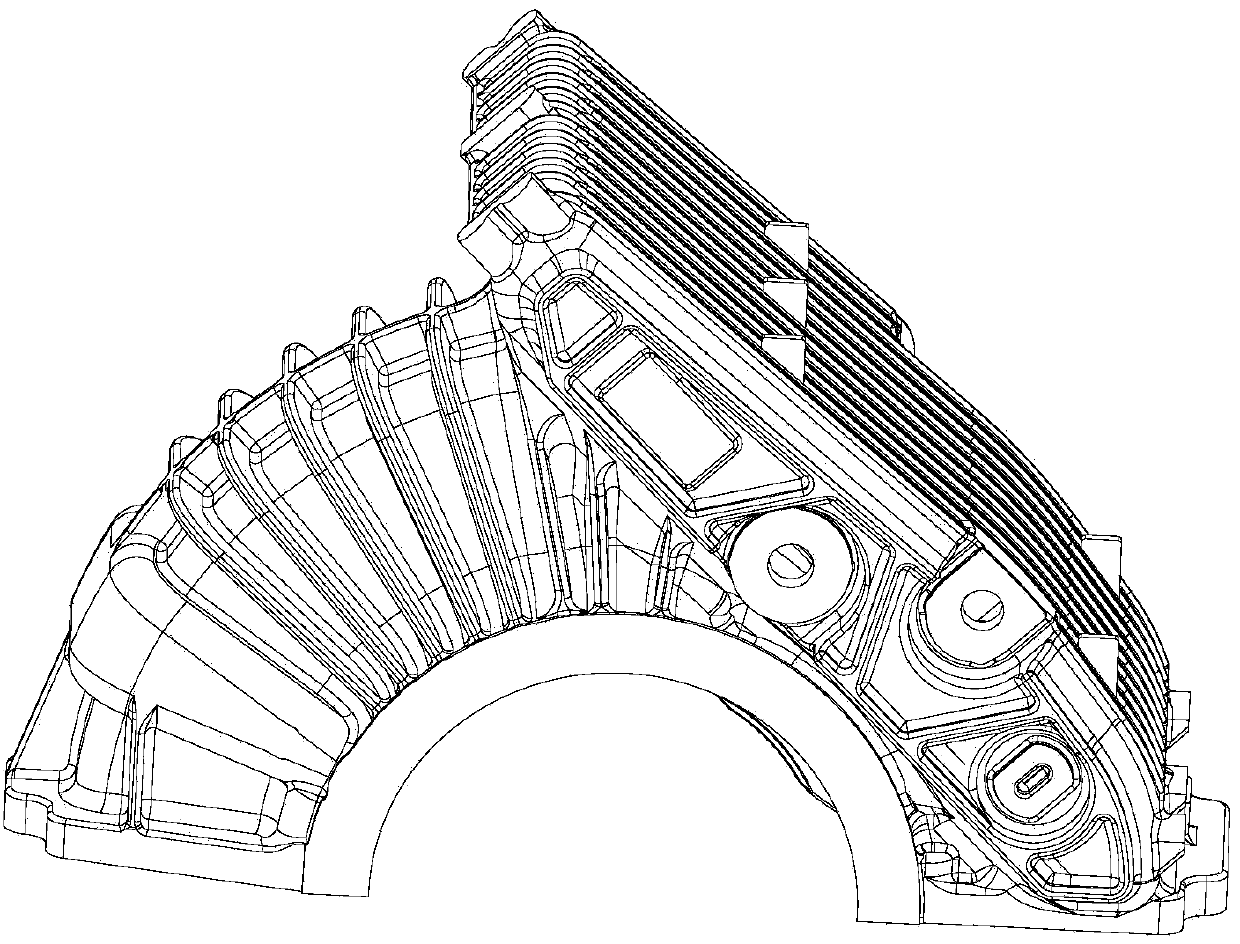

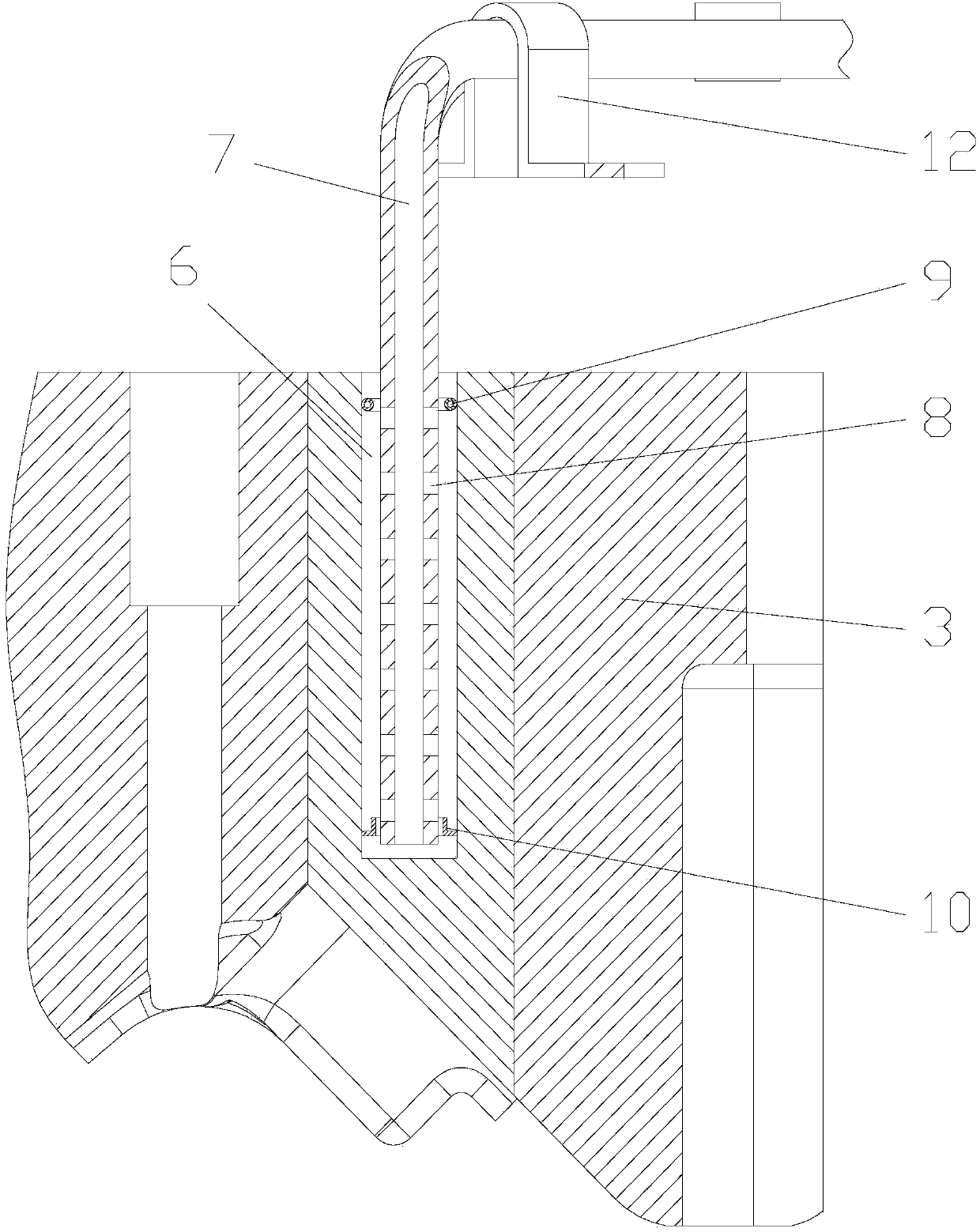

[0018] figure 1 It is a structural schematic diagram of the present invention; figure 2 Outline drawing of a large gearbox with multiple isolated thermal joints; image 3 It is a partial view of the upper mold; Figure 4 It is a schematic diagram of the structure of the sand core in the inner cavity, as shown in the figure: the low-pressure casting mold for the large-scale gear box body with multi-point isolated heat joints in this embodiment includes a bottom mold 1, a left mold 2, and a right mold (about the same as the left mold 2) Relatively set), upper mold 3, front core-pulling slider 4, rear core-pulling slider (set opposite to the front and back of the front core-pulling slider 4) and inner cavity sand core 5, and also includes cooling for at least the upper mold 3 The cooling system; the cooling system includes at least the cooling hole 6 opened on the upper mold 3 and the cooling pipe 7 extending into the cooling hole 6 for continuously spraying cooling medium int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com