Preparing method of triangular flaky nanometer silver particles

A nano-silver particle and flaky technology, which is applied in the field of preparation of triangular flaky nano-silver particles, can solve the problems of low output and inability to produce in large quantities, and achieve high output, simple operation, and suitable for large-scale production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

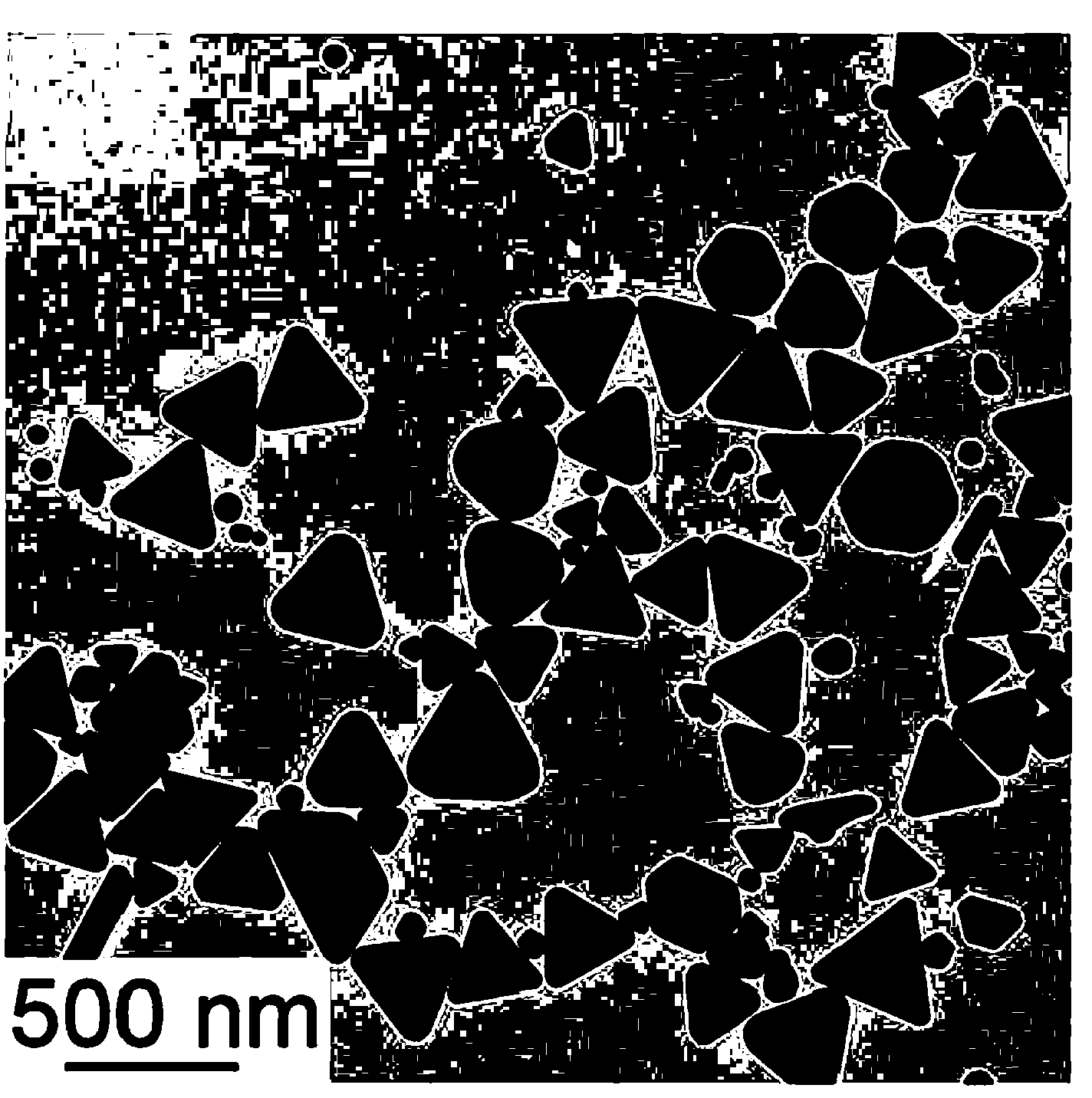

[0011] see figure 1 , the invention provides a kind of preparation method of triangular flaky nano-silver particle, it comprises the following steps:

[0012] S1: Silver trifluoroacetate, polyvinylpyrrolidone (PVP) and benzyl alcohol are mixed in a reaction kettle, and a mixture is obtained after stirring evenly;

[0013] S2: adding a metal salt to the mixture, stirring at room temperature to obtain a clear solution;

[0014] S3: heating the clear solution to 120-150 degrees Celsius in the reactor, and reacting for a period of time to obtain a reaction product; and

[0015] S4: The reaction product is centrifuged and washed to obtain triangular sheet-shaped silver nanoparticles.

[0016] In step S1, the mass of the silver trifluoroacetate is 19-20 mg. The molecular weight of the PVP is about 10,000, and its mass is 0.04-0.06 grams. The benzyl alcohol is 4-6 milliliters. In this embodiment, preferably, the mass of the silver trifluoroacetate is 20 mg, that is, 0.09 mmol; t...

Embodiment 1

[0022] The preparation method of the triangular flaky nano-silver particles of the present embodiment has the following steps:

[0023] Step 1, the silver trifluoroacetate of 0.09mmol and the polyvinylpyrrolidone (PVP, molecular weight M w ≈10,000) was dissolved in 5 ml of benzyl alcohol and stirred at room temperature for 10 minutes, at which time the solution was colorless;

[0024] Step 2, adding 0.0025mmol of aluminum nitrate and 0.0025mmol of iron nitrate to the mixing system of the above step 1, and continuing to stir until the aluminum nitrate is completely dissolved;

[0025] Step 3: Put the reaction solution obtained in Step 2 in a reaction kettle, and react in a constant temperature box at 120 degrees Celsius for 6 hours to obtain a product.

[0026] Step 4: After centrifugal separation and washing, the final product is obtained.

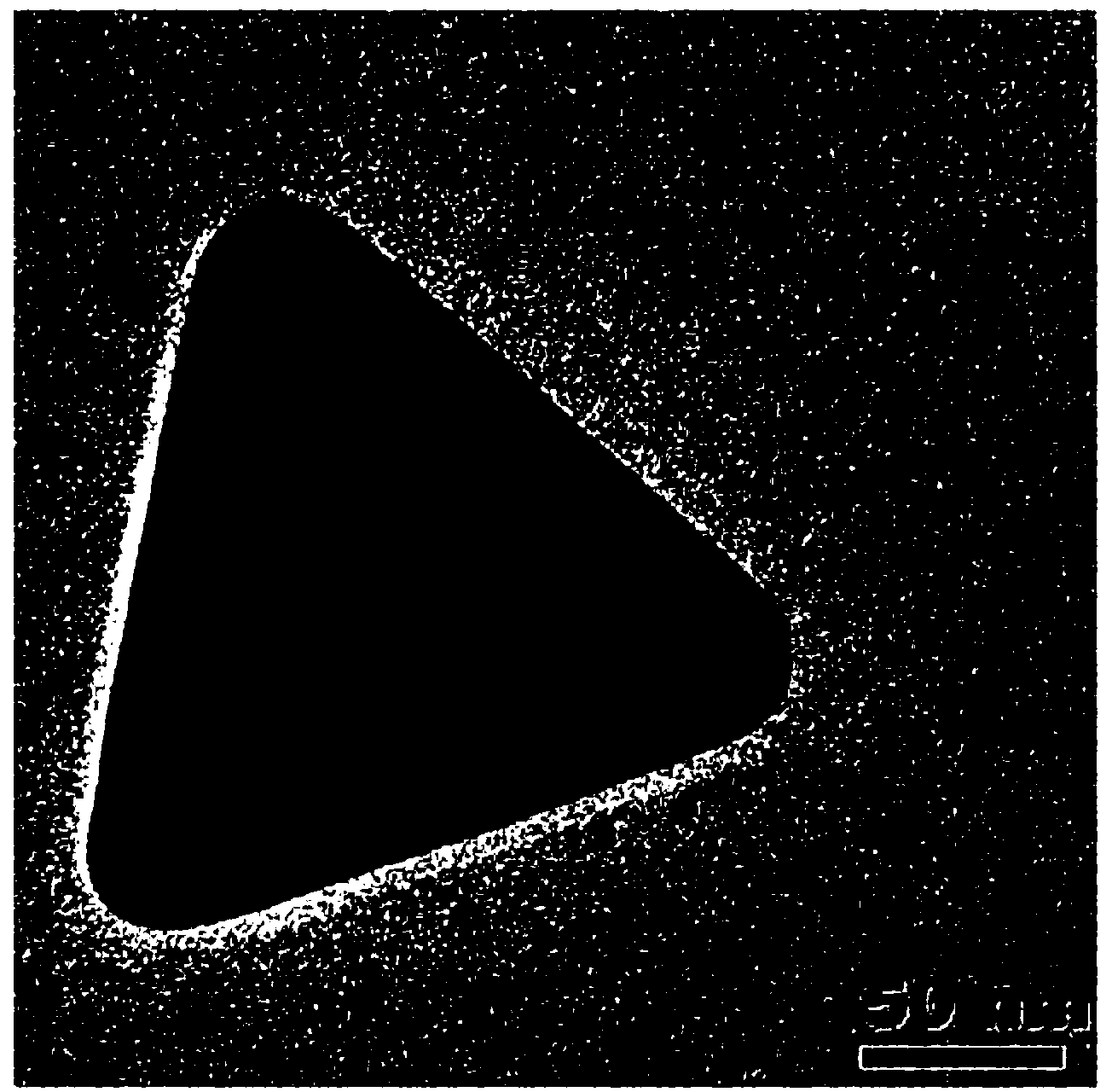

[0027] See figure 1 , most of the products prepared in this example are triangular sheet-shaped silver nanoparticles with a size of 10...

Embodiment 2

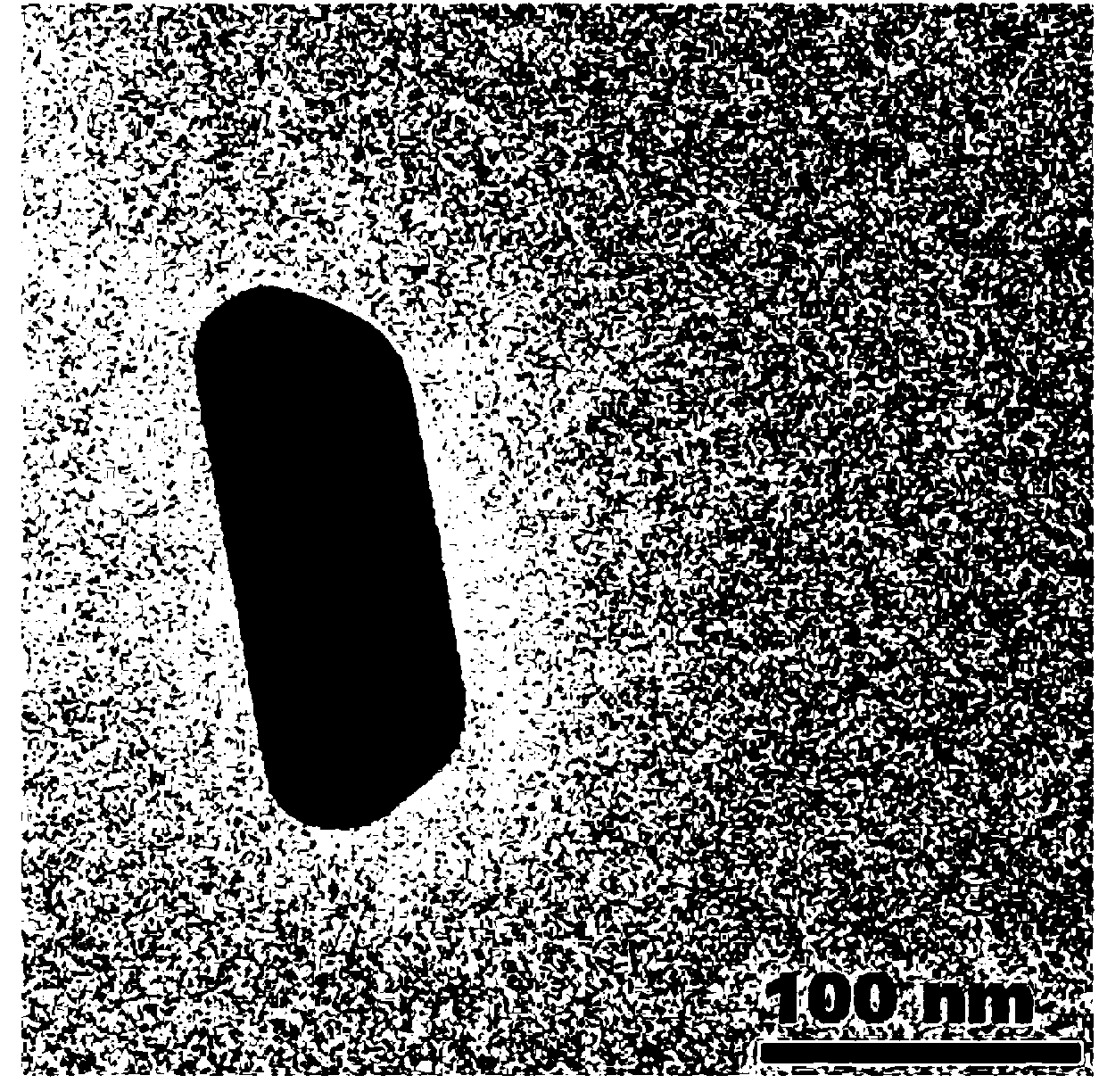

[0029] The rest of the preparation method of the triangular nano-silver particles in this example is the same as in Example 1, except that the metal salt added in step 2 is aluminum nitrate, and its molar weight is 0.0025 mmol. The product is a triangular sheet-shaped triangular sheet-shaped nano-silver particle with a thickness of 100 nm to 200 nm, and contains some spherical particles. The yield of the triangular-shaped sheet-shaped silver nano-particle in the product is lower than that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com