Nuclear island primary coolant circuit main pipe installation method

An installation method and main pipeline technology, applied in arc welding equipment, manufacturing tools, welding equipment, etc., to achieve the effect of saving construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

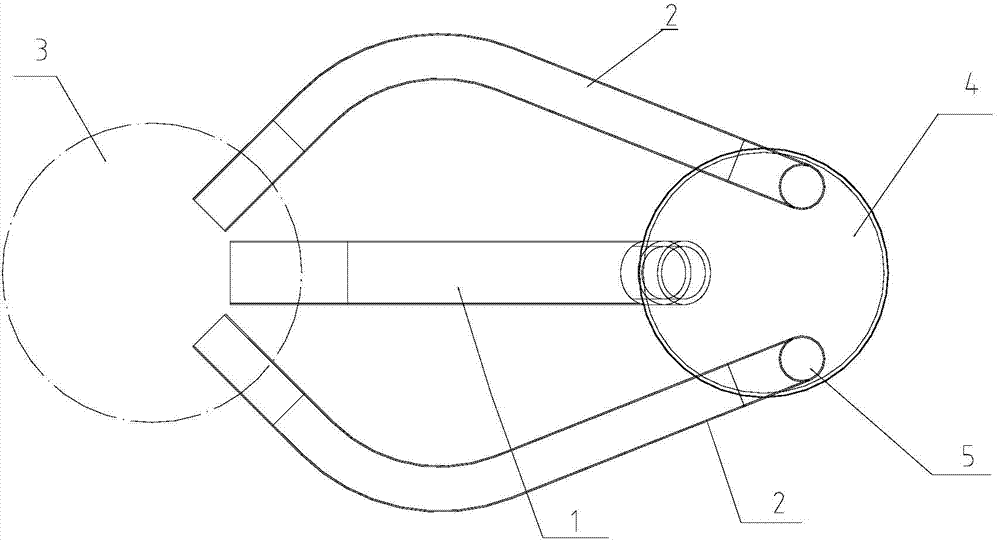

[0021] Embodiment 1 A nuclear island primary circuit main pipeline installation method, comprising the following steps:

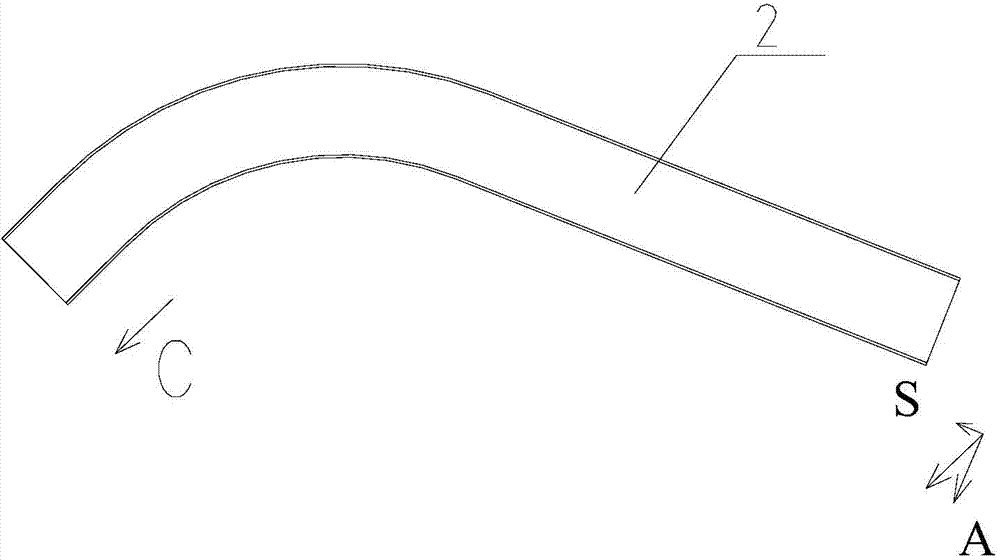

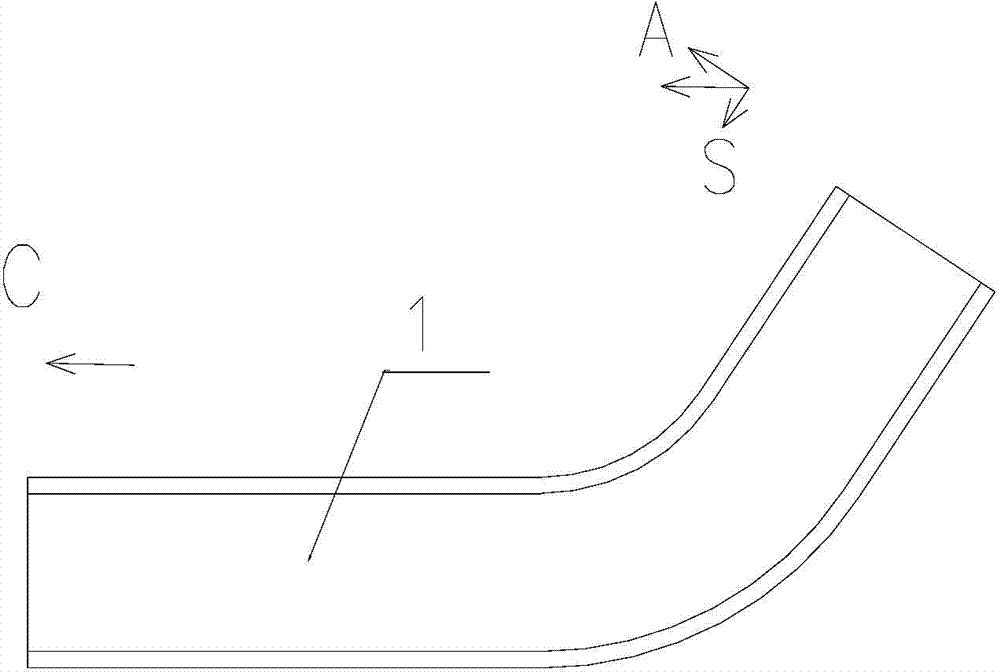

[0022] 1) By performing a welding test on weld joints of the same specification and material of the main pipeline, the shrinkage when obtaining the 50% thickness of the weld under the specified pairing conditions is 6.5mm and 4.5mm respectively; wherein, the main pipeline Including one hot section 1 of the main pipeline and two cold sections 2 of the main pipeline; among them, the pairing condition refers to: the pairing gap is 0.2mm, and the wrong side is 0mm;

[0023] 2) Preset the welding parameters required for welding with narrow gap automatic argon arc welding technology; the welding parameters mentioned here refer to pulse frequency: 2.0Hz; pulse width: 50%; swing width: 0.35~0.65in, internal dwell Time: 0.2~0.4s; Outside residence time: 0.2~0.4s; Walking delay: 2~3s; Wire feeding delay: 2~3s; Argon flow: 25~55L / min, Walking speed: 3.0-5.0in / min; w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com