Method for forging high cone stepped forging piece with axial hole

A technology of axial hole and step type, which is applied in the forging field of high-cone step forgings with axial hole, can solve the problems of material consumption and energy consumption, and achieve the effect of reducing the wear of the punch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

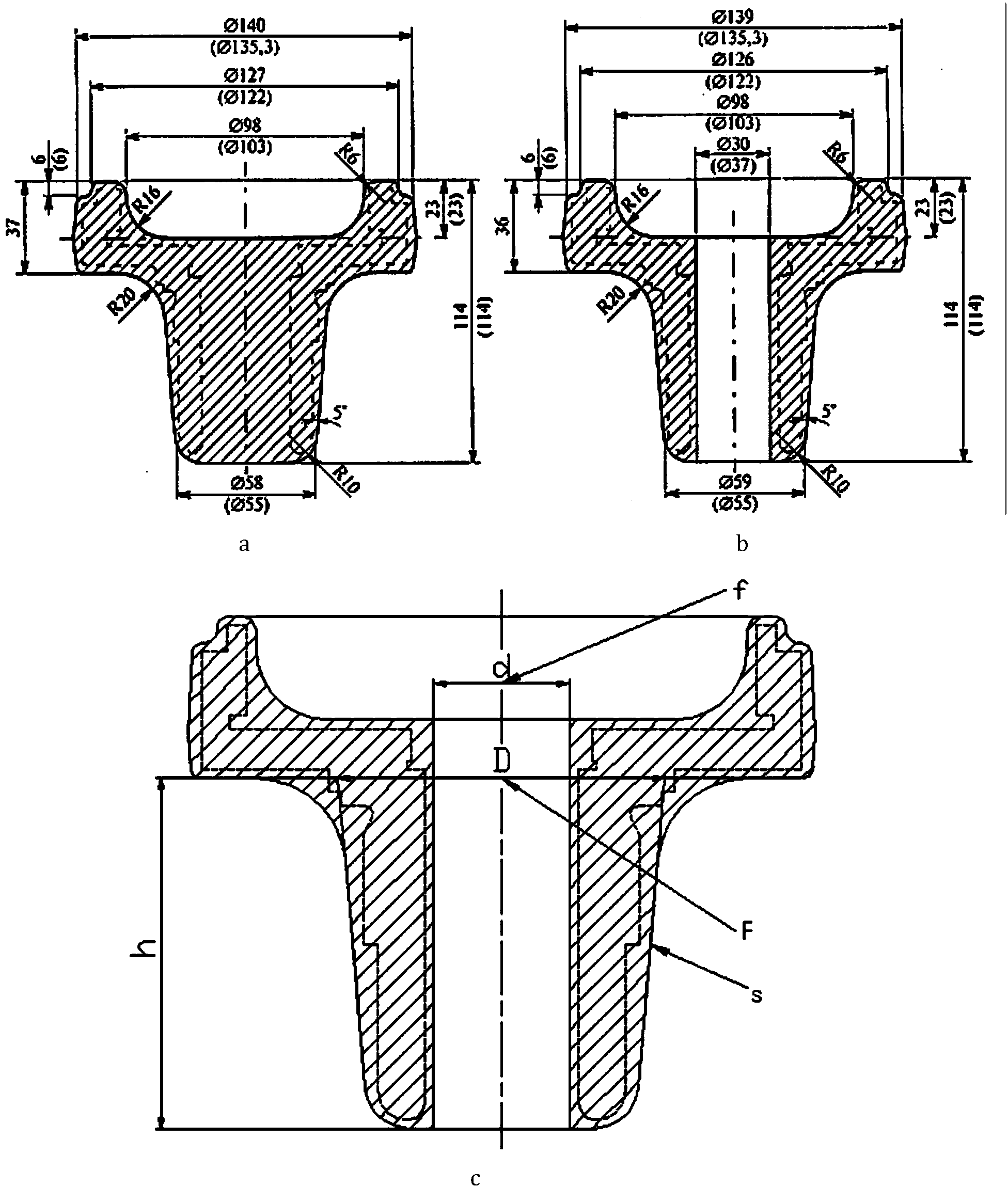

[0023] Using this method and using 40Cr as the material, the die forging process of hollow tooth clutch forging is designed. Such as figure 1 As shown, a is the forging diagram of the current application process, and b and c are the forging diagrams of this embodiment.

[0024] The current production process of toothed clutch die forgings is carried out on a non-mechanized die forging production line on a hot die forging press with a nominal pressure of 25MN, and the average die forging productivity is 95 pieces / hour. The die forging blank is heated in a chamber flame furnace, and it is impossible to obtain an axial hole under this process condition.

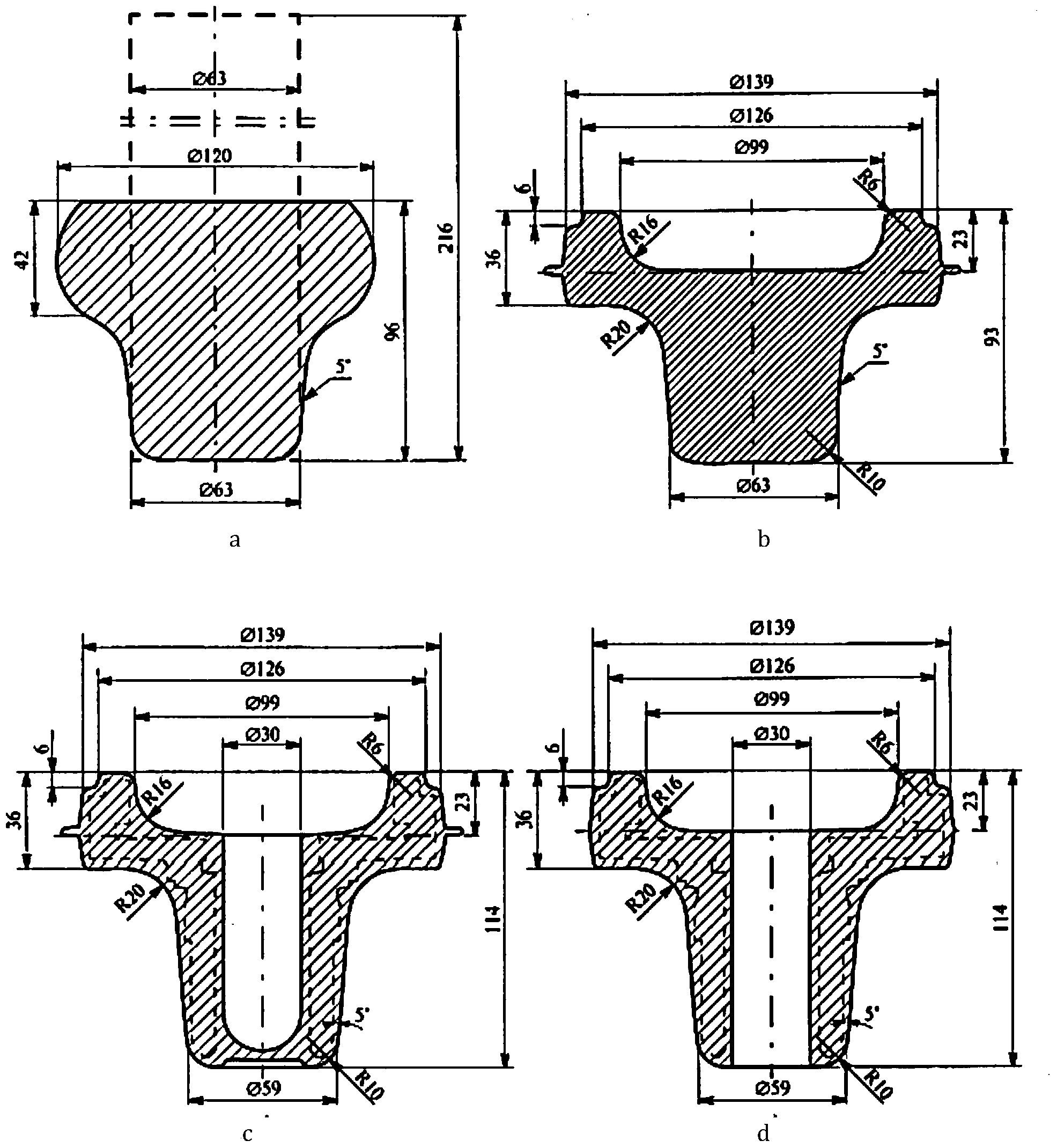

[0025] Such as figure 2 As shown, in this embodiment:

[0026] Step 1, place the blank on a 16MN hot die forging press after intermediate frequency induction heating;

[0027] Step 2, proceed as figure 2 Upset as shown in a to obtain flange wrinkle; then proceed as follows figure 2 Die forging shown in b to obtain semi-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com