Method and device for synchronously lifting steel reinforcement cage

A steel cage and equipment technology, applied in the direction of ceramic molding machines, manufacturing tools, etc., can solve the problems of unstable operation, high operating cost, cumbersome operation, etc., and achieve the effects of stable operation, pollution avoidance and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

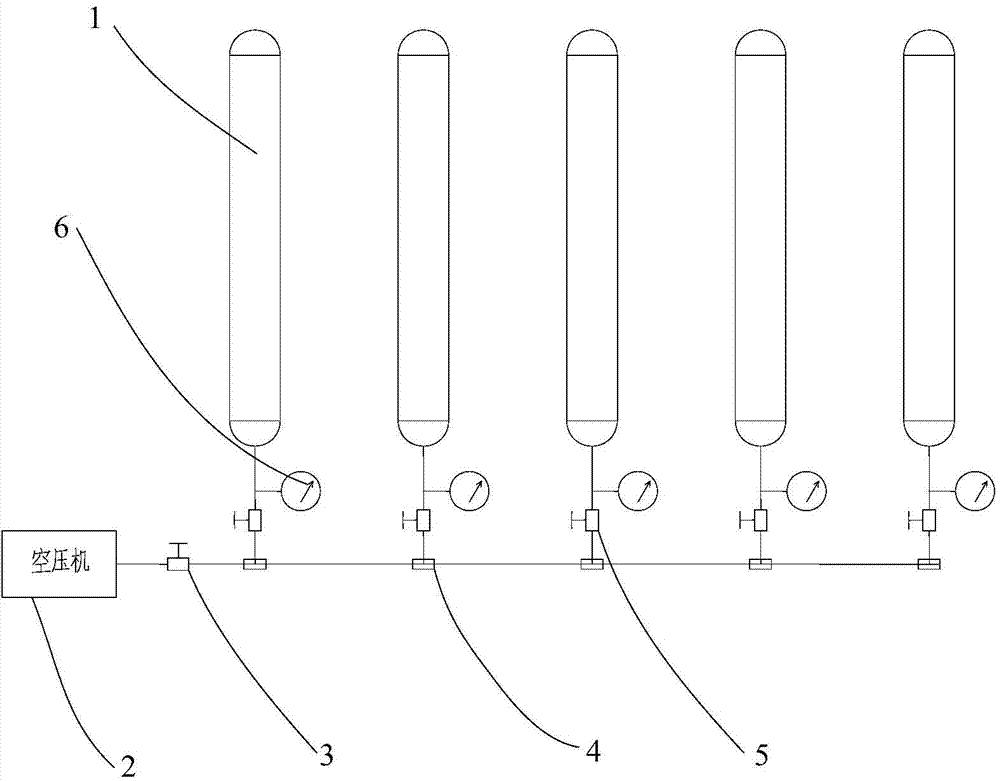

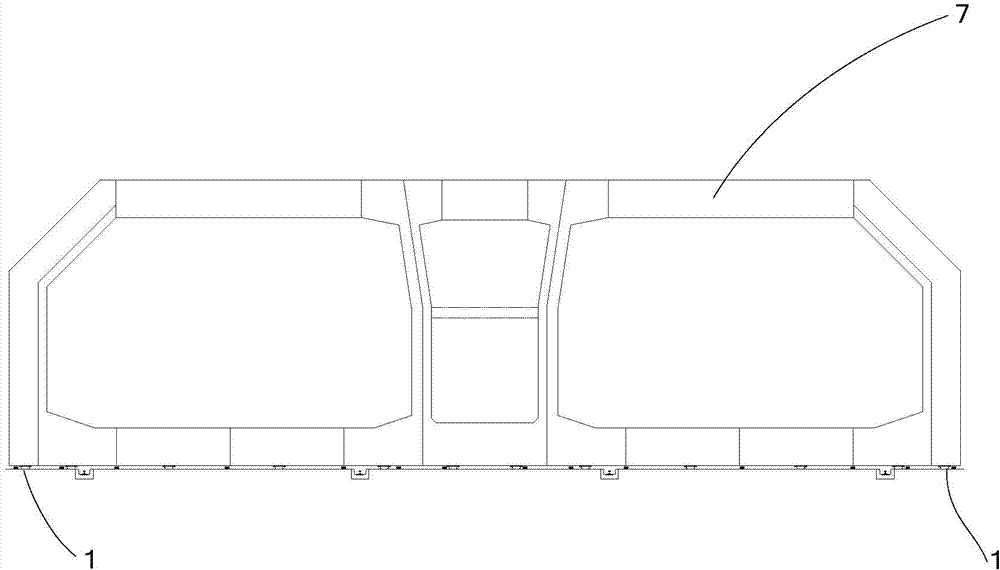

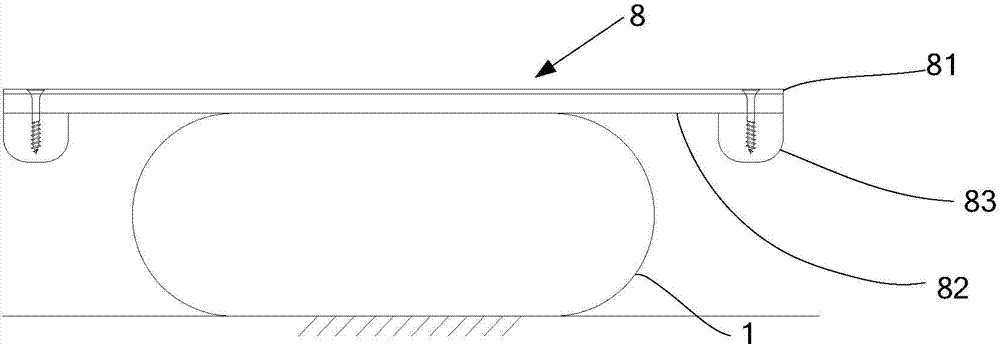

[0032] Such as figure 1 , image 3 As shown, this implementation provides a synchronous lifting reinforcement cage equipment in the process of manufacturing tunnel immersed tubes, and the equipment adopts the airbag jacking method. The device comprises a plurality of airbags 1 , an airbag backing plate 8 and an air compressor 2 , the airbag backing plate is arranged on the upper surface of the plurality of airbags, and the air compressor communicates with the plurality of airbags through pipelines. Such as figure 2 As shown, the airbag is in contact with the bottom of the reinforcement cage 7 through the airbag backing plate to increase the lifting contact area. The pipeline includes a trachea main circuit, and the trachea main circuit is provided with a plurality of trachea branches, and the trachea main circuit is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com