Multicolor 3D (three-dimensional) printer

A 3D printer and multi-color technology, applied in the field of 3D printing, can solve the problems that the color appearance of the model cannot be realized, and cannot further satisfy people, and achieve the effect of simplifying the structure and saving energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

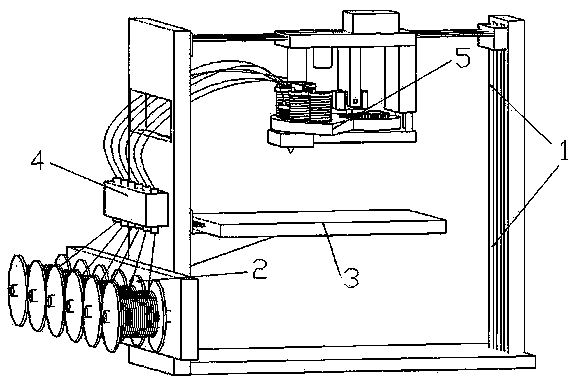

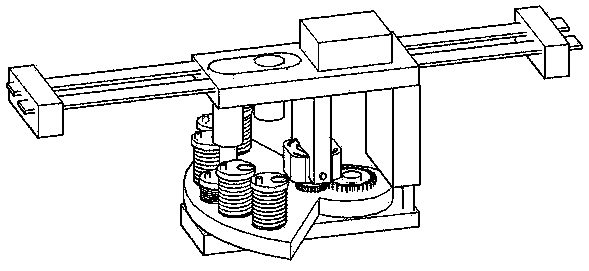

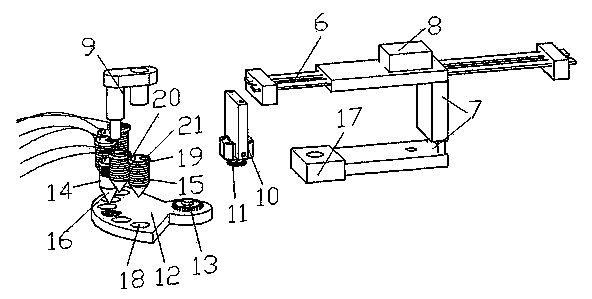

[0008] Embodiments are described in detail with reference to the accompanying drawings. A multi-color 3D printer, including a printer frame 1, a printing material mounting frame 2, a printing platform 3, a wire feeding module 4 and a printing color changing mechanism 5, wherein the two side plates of the printer frame 1 are fixed on both sides of the bottom plate, and the two sides The top of the board is connected by a guide rail 6, and vertical guide rails 6 are respectively provided on the inner sides of the two side plates; the printing platform 3 is slidably matched with the vertical guide rails 6 on the inner side of the side plates, and is lifted and lowered by computer control; The printing material mounting frame 2 is fixed on the outside of the side plate, and the printing material mounting frame 2 is provided with 6-8 printing material mounting heads, and ABS or PLA material discs are installed on the printing material mounting heads; the wire feeding The module 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com