A polypropylene resin composition for making high -temperature cooking CPP film and its high -temperature cooking CPP film

A polypropylene resin and high-temperature cooking technology, which is applied in the field of polypropylene resin composition, can solve the problems such as the deterioration of film quality, poor film-forming processability, poor discoloration resistance, etc. The effect of improved, good processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

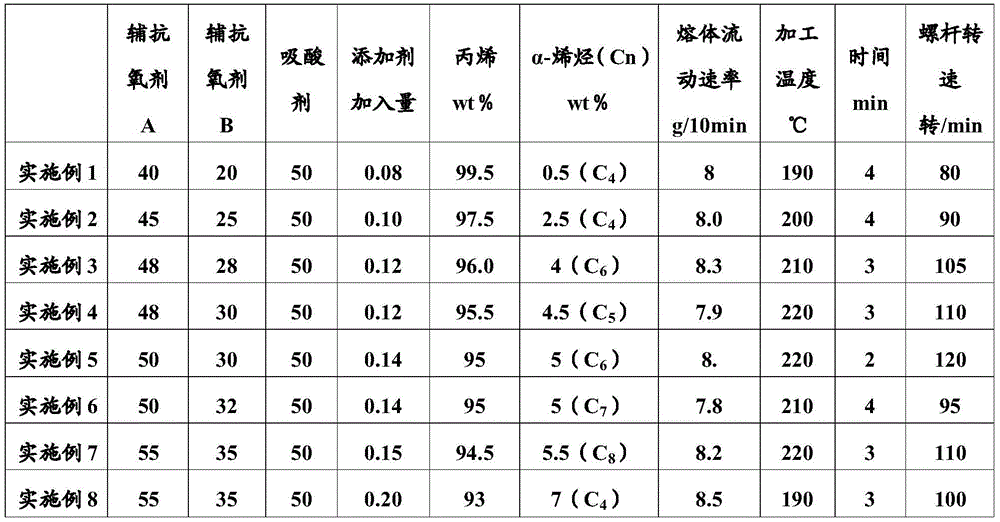

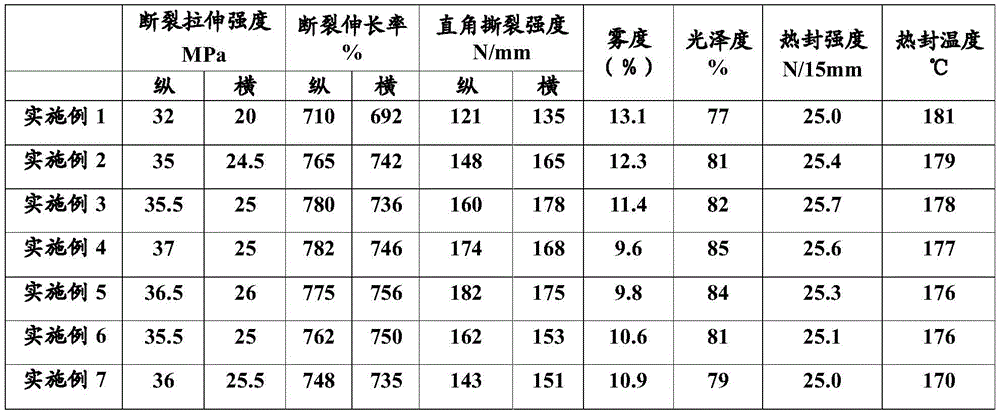

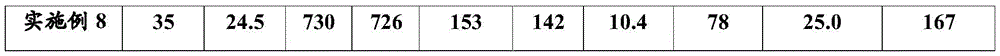

Embodiment 1~8

[0030] Take 500 kg of powdery polypropylene resin base material (light milky white powder, purchased from Shanghai Petrochemical Co., Ltd.), add each component of the additive according to the required ratio, and mix well. The material is put into a twin-screw extruder for melt mixing and granulation. The residence time of the material in the screw is 2-4 minutes. The temperature of the screw is controlled at 190-220°C, and the speed of the screw is controlled at 80-120 rpm. The obtained polypropylene resin particles are finished products after being cooled and dried. Each embodiment takes 500kg sample.

[0031] The polypropylene resin base material is composed of 93-99.5wt% propylene and 0.5-7wt% C 4 -C 8 The polypropylene copolymer obtained by copolymerization of α-olefin has a melt flow rate of 7.0-10.0 g / 10 min and an isotacticity of 95.0-98.0%.

[0032] The additive is composed of primary antioxidant, secondary antioxidants A and B and acid absorbing agent, among which...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com